3

Function monitoring

To increase operating safety, the Nivotester is equipped with a function monitoring system.

A fault is indicated by a red LED and causes the level alarm relay in the affected channel as well

as the fault alarm to drop out. A fault is signalled when the Nivotester receives no more current

pulses. This could occur for example in the event of a short-circuit, an interruption in the signalling

line to the measuring sensor, vibrator corrosion in the Liquiphant, a defect in the measuring

sensor electronics or a defect in the input circuit of the Nivotester. The function of each channel

can be monitored by pressing the test button. The power supply to the sensor is then interrupted.

Simplified iterative test for Liquiphant M and Liquiphant S (HT)

Regular function checks are a statutory requirement for overspill protection systems. For the

Nivotester and the downstream plant sections, there is the possibility of a function test without

starting up or removing the sensor. For this reason, the Nivotester has a test button on the front

panel for each singal input. Pressing the test button interrupts the power supply. When the test

button is released, the power supply is returned to the Liquiphant and the FEL 57 and the test

phase begins. You can find detailed information on this in KA 147F.

L00-FTL325Px-19-06-xx-xx-001

Two-point control (∆s)

Two-point control is possible in one tank using the three-channel Nivotester (e.g. for pump

control). The switching hysteresis is specified by the installation location of the two measuring

sensors.

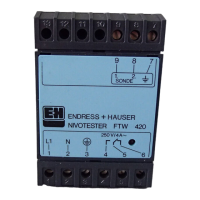

Measuring system A simple measuring device consists of one to three measuring sensors, a 1- or 3-channel

Nivotester and control or signal devices. A Liquiphant M, Liquiphant S (high temperature) or

Soliphant can be used as measuring sensor.

[Ex ia]

CH1 CH2

CH3

CH1 CH2 CH3

T

FTL 325 P

Loading...

Loading...