Do you have a question about the EnerSys Hawker Perfect Plus and is the answer not in the manual?

Overview of ATEX certified batteries for use in hazardous areas with risks of explosion.

Details ATEX Directive compliance and lists EC type-examination certificates.

Specifies that charging is prohibited in a hazardous area.

Highlights critical safety warnings for handling, charging, and working with batteries.

Explains the role of local authorized service engineers for assistance.

Provides guidance on using approved equipment for lifting and moving heavy batteries.

Instructions for receiving and inspecting the battery for any damage.

Details the steps for safely commissioning the battery before initial operation.

Includes recharging, checking charger operation, and electrolyte levels.

Involves checking cell connections, insulation, and vent plugs.

Requires measuring cell voltages, electrolyte density, and temperature.

Covers insulation resistance testing and pump air filter checks.

Guidelines for optimal discharge to maximize battery life and performance.

Details safe charging methods and restrictions in zoned areas.

Instructions on how to accurately measure the electrolyte's specific gravity.

Explains how temperature affects performance and lists operational limits.

Discusses environmental conditions and material compatibility with explosive atmospheres.

Covers protection against hazards and resistance to aggressive substances.

Guidelines for keeping the battery clean and storing it properly when not in use.

Advises on how to report and resolve battery or charger malfunctions.

Explains the system's use for automatically maintaining electrolyte levels.

Covers system function, connection types, filling time, pressure, purity, piping, and flow control.

Describes the system's benefits for heavy-duty use and optimizing charge.

Details how the diaphragm pump circulates air to prevent electrolyte stratification.

Recommends regular checks and replacement of the pump air filter.

Guides on checking for leakage and using genuine spare parts.

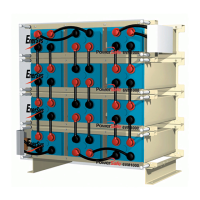

This document describes the Hawker® Perfect Plus™/Water Less® ATEX certified batteries, which are motive power batteries designed for use in hazardous areas with risks of explosion due to gas or dust. These batteries are certified for increased safety "e" and comply with ATEX Directive 2014/34/EU.

Hawker ATEX certified batteries are designed to provide motive power in applications within hazardous areas, such as electric counter-balance, reach, and pallet trucks, as well as floor sweepers and other cleaning equipment. The patented ventilation design allows these traction batteries to fit within existing DIN and British standard crate sizes while offering the specified capacity. The cells and connectors comply with IP65, and the crates with IP23.

The batteries are certified for:

The electrolyte circulation system (optional accessory) is based on the principle of pumping air into individual battery cells. This system prevents electrolyte stratification and optimizes battery charge with a charge factor of 1.07. It is particularly beneficial for heavy-duty use, short charge times, boost or opportunity charging, and high ambient temperatures. The air stream is continuous or pulsed depending on the battery voltage and pump type, with the air supply adjusted according to the number of cells. The pipe system to the individual battery cells must follow the existing electrical circuit to reduce the risk of current leakage in the presence of electrolytic gas causing an explosion (EN 62485-3).

The Aquamatic water refilling system (optional accessory) automatically maintains nominal electrolyte levels. A valve and a float control the topping-up process, allowing water flow into each cell and closing the valve when the correct water level is reached. The charging gases escape through the vent on each cell.

| Brand | EnerSys |

|---|---|

| Model | Hawker Perfect Plus |

| Category | Camera Accessories |

| Language | English |