Page 5

Installation and Operation Requirements - Solution 2.3

ENGLISH

2. General Information

2.1 Performances

Values are as measured per test method, except for the recommended heating area, firebox volume,

maximum burn time and maximum heat output.

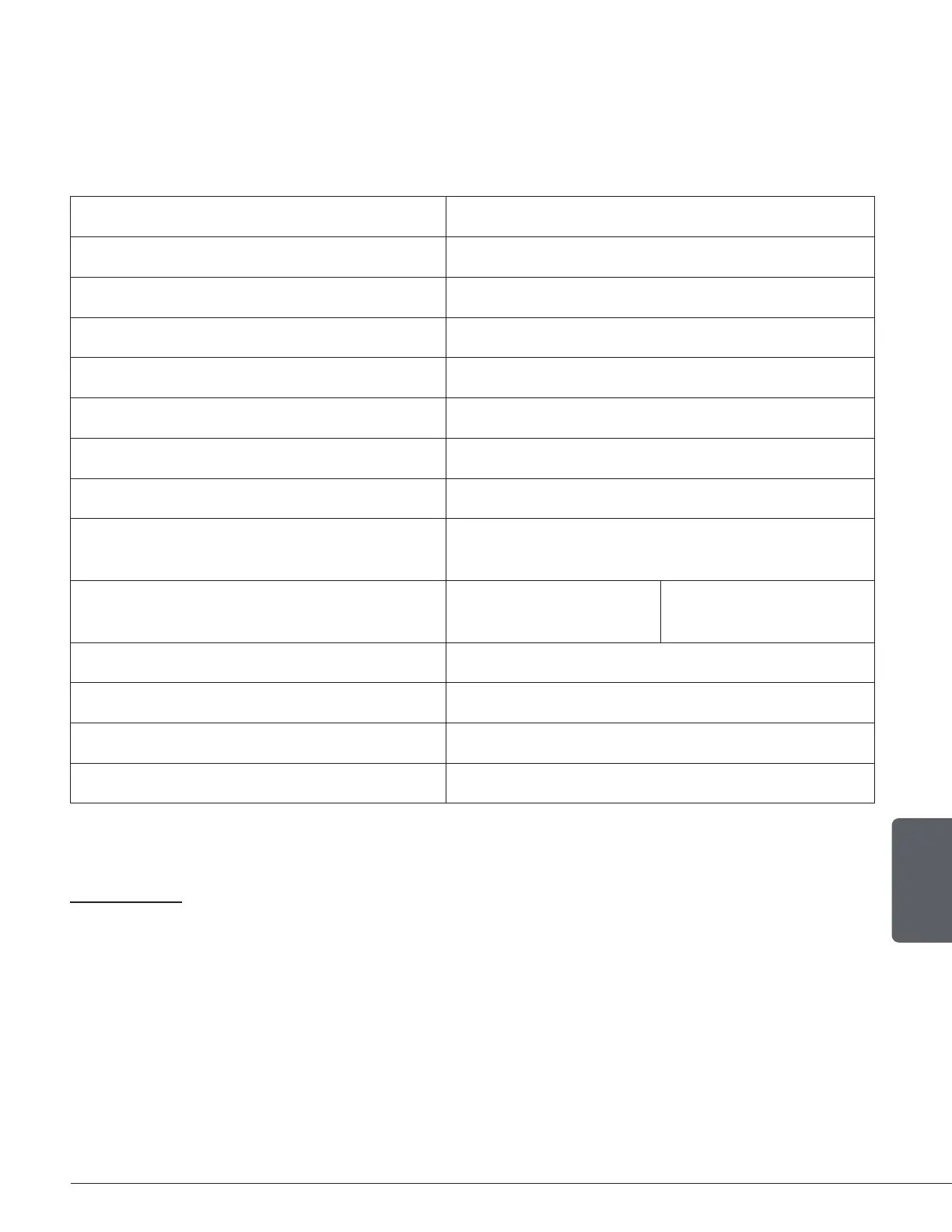

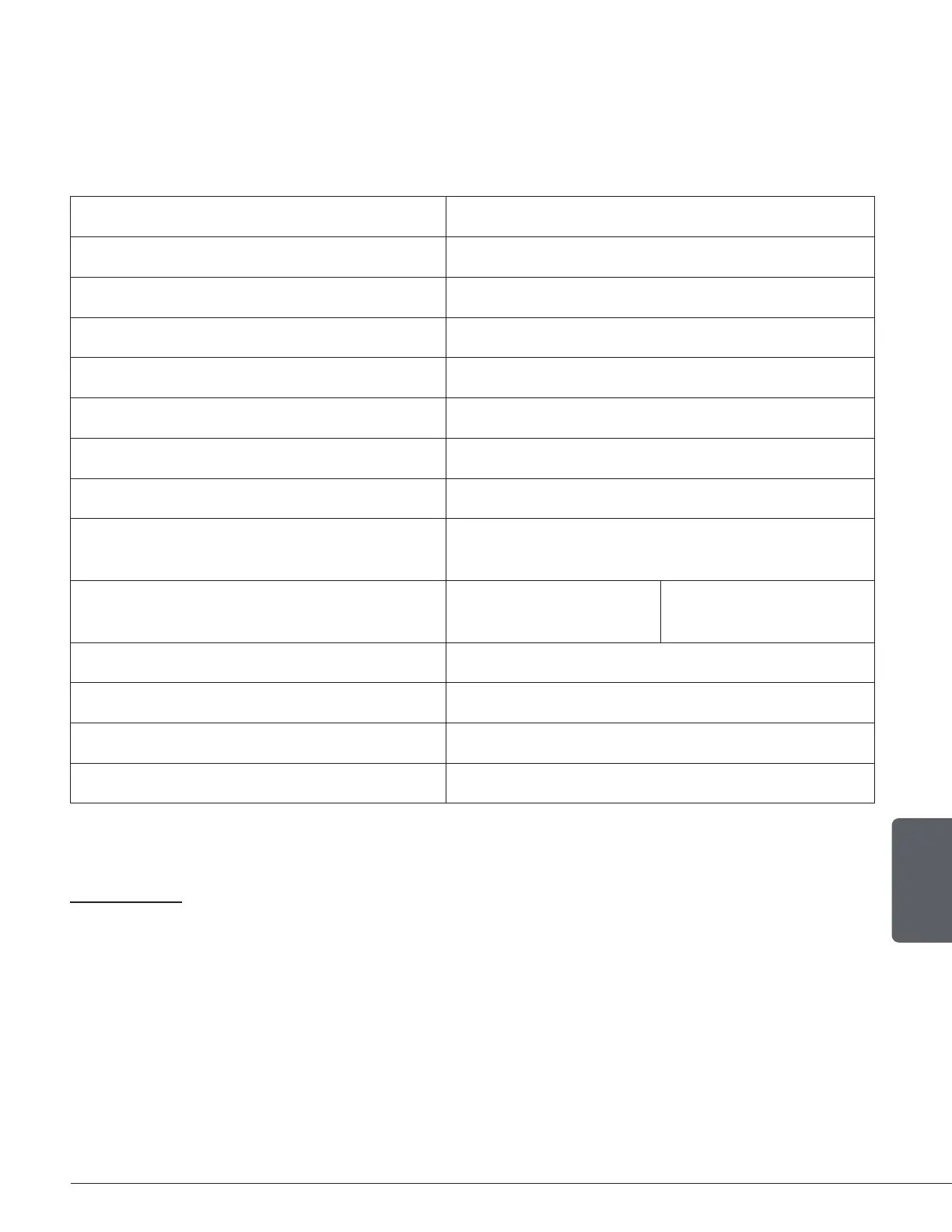

Model Solution 2.3 (EB00063)

Combustion Technology

Non-catalytic

Fuel Type

Dry Cordwood

Recommended heating area (sq. ft.

.

)

1

500 to 2,100 ft

2

(47 to 195 m

2

)

Total firebox volume 2.4 ft

3

(0.068 m

3

)

Loading volume EPA

2.02 ft

3

(0.057 m

3

)

Maximum burn time

1

8 hours

Maximum heat output (dry cordwood)

2

75,000 BTU/h (22.0 kW)

Overall heat output rate (min. to max.)

2 3

14,800 BTU/h to 28,600 BTU/h

(4.34 kW to 8.38 kW)

Average overall efficiency

3

(Dry cordwood)

69 % (HHV)

4

74 % (LVH)

5

Optimum efficiency

6

77 %

Optimum overall efficiency

7

75 %

Average particulate emissions rate

8

1.54 g/h (EPA / CSA B415.1-10)

9

Average CO

10

89.4 g/h

1

Recommended heating area and maximum burn time may vary subject to location in home, chimney draft,heat loss factors, climate, fuel type

and other variables. The recommended heated area for a given appliance is dened by the manufacturer as its capacity to maintain a minimum

acceptable temperature in the designated area in case of a power failure.

2

The maximum heat output (dry cordwood) is based on a loading density varying between 15 lb/ft

3

and 20 lb/ft

3

. Other performances are based on

a fuel load prescribed by the standard. The specied loading density varies between 7 lb/ft³ and 12 lb/ft

3

. The moisture content is between 19%

and 25%.

3

As measured per CSA B415.1-10 stack loss method.

4

Higher Heating Value of the fuel.

5

Lower Heating Value of the fuel.

6

Optimum overall efciency at a specic burn rate (LHV).

7

The optimum heat transfer efciency is for the low burn rate and represents the appliance's ability to convert the energy contained in the wood logs

into energy transferred to the room in the form of heat and does not take into account the chemical losses during combustion.

8

This appliance is ofcially tested and certied by an independent agency.

9

Tested and certied in compliance with CFR 40 part 60, subpart AAA, section 60.534(a)(1(ii) and ASTM E3053-17. Based on ALT-125 sent by EPA on

February 28th, 2018.

10

Carbon monoxide.

Loading...

Loading...