A DJ & DG MANUAL

15 of 34 May 12 R2

1) The field wiring load depends on the actual load on a particular control circuit the field wiring is

connected to. Refer to the internal wiring diagram of the unit.

2) The table above is based on a maximum 10% voltage drop on a 24V control circuit. Wire size was

calculated using the following formula:

CM = (25 x I x L ) / V

Where CM is circular mils of conductor for a constant load of I amps, wire length L in feet from the

unit to the field device and back, and voltage drop V.

When connecting to a three phase power supply, check for the correct rotation of all motors and fans. If the

rotation is incorrect, reverse the rotation at the incoming power only. All electrical conduit outlets in the

control panel must be sealed to prevent moist building air from migrating to the control panel.

All penetrations through the unit walls must be caulked and sealed to prevent air and/or water from

entering the unit.

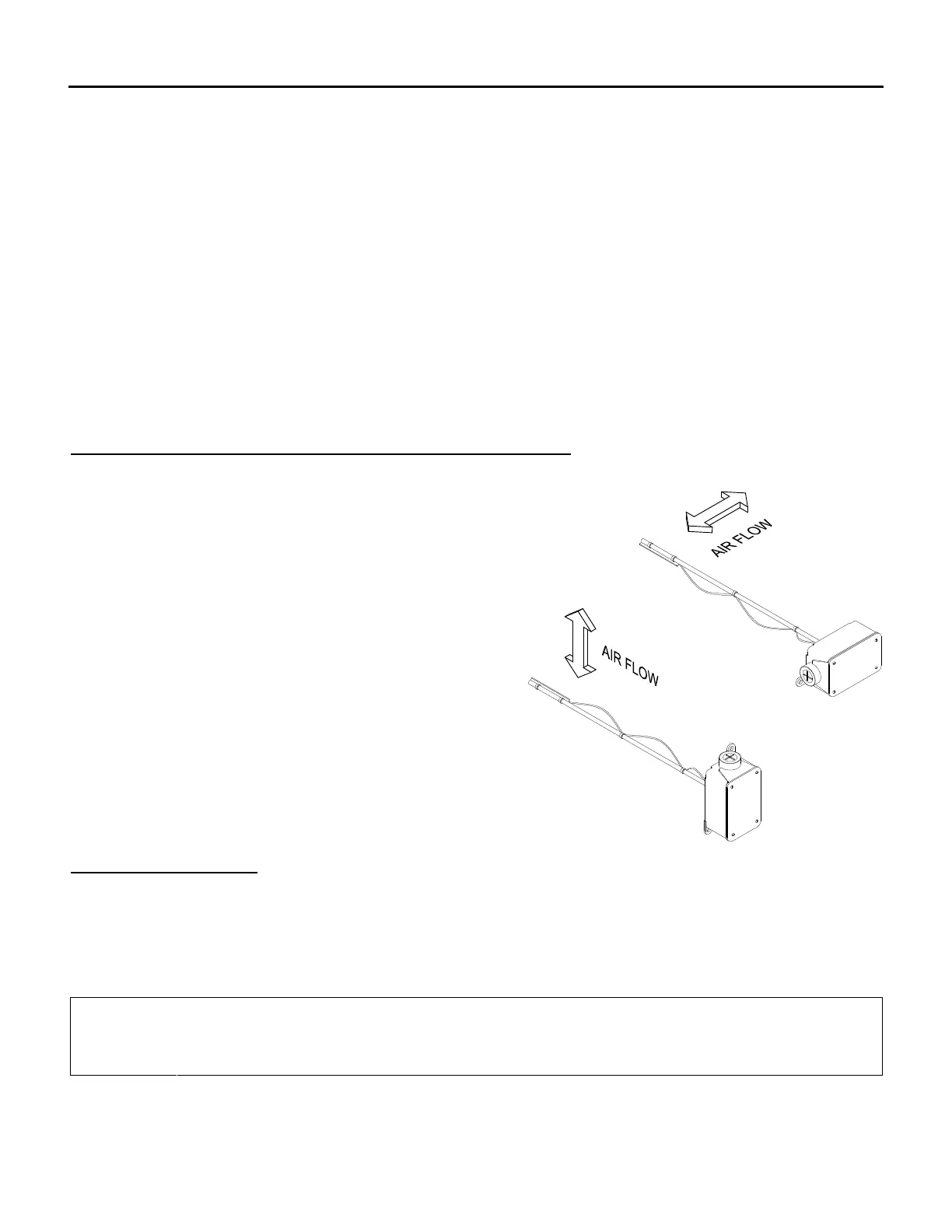

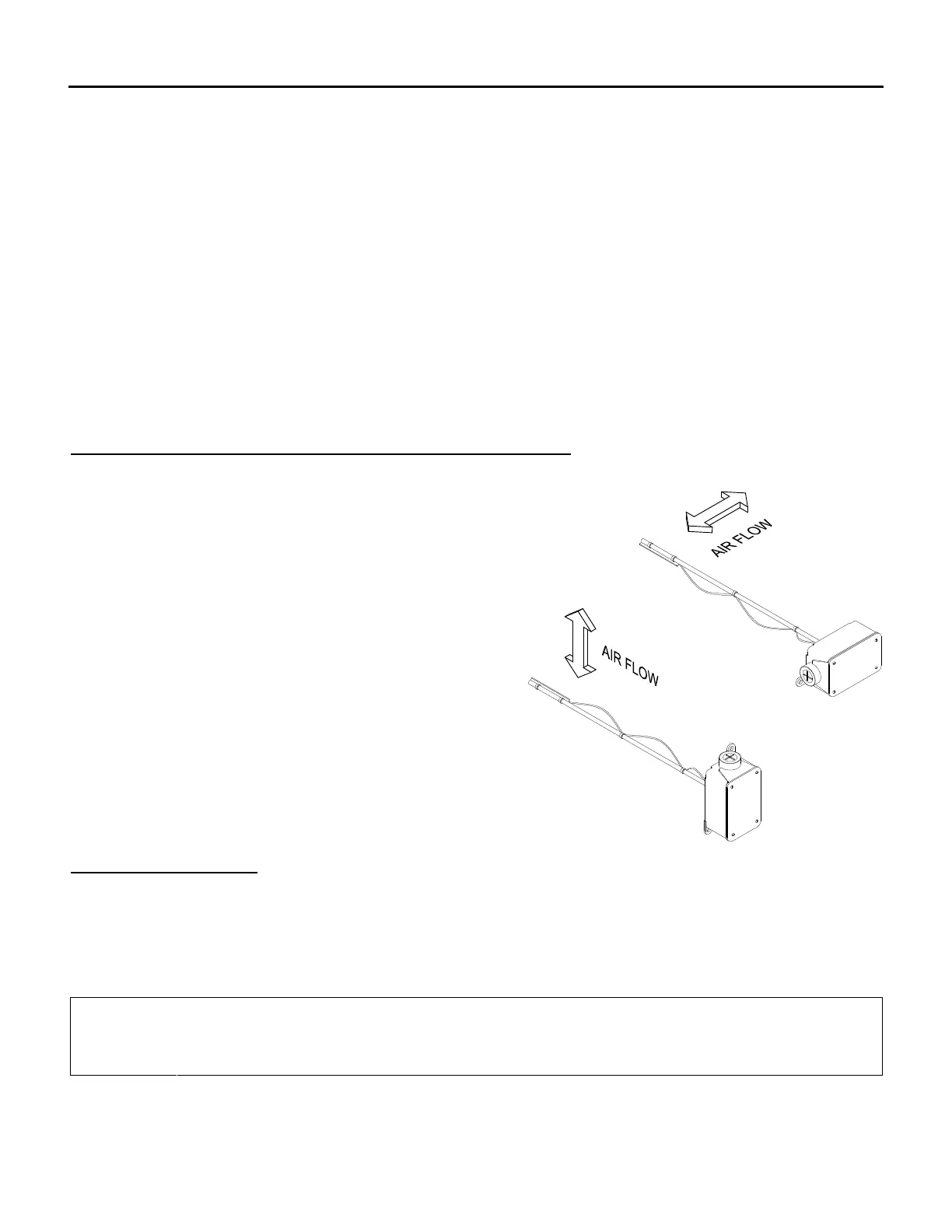

DUCT MOUNTED TE-6000-EA3 TEMPERATURE SENSOR

Some applications require field installed discharge air

sensors.

The sensor strip must be parallel to the air flow. The

sensor should be mounted near the center of a straight

duct 5 to 10 feet (1500 to 3000mm) downstream of the

supply air connection to the Engineered Air unit. Avoid

installing near duct transitions or elbows.

Use twisted pair or shielded wiring. The ground shield

should be grounded only at the unit control panel end.

Protect the opposite end ground and any unused wire with

electrical tape.

When installing an Engineered Air TE-6000-EA3 duct

mounted temperature sensor, the sensor strip must be

parallel to the air flow as shown.

COIL CONNECTIONS

This equipment may require field connection of water, steam or refrigerant coils. For proper operation

airflow must be counterflow to the flow of the fluid. The inlet water connection is normally at the bottom of

one header and the outlet water connection at the top of the other header. The steam connection is at the

middle of the supply header and the condensate is at the bottom of the other header.

Caution:

m

Use a backup wrench on threaded coil connections when installing piping.

For refrigerant coils, all piping is to be installed by a qualified refrigeration mechanic. All refrigeration

specialties shall be installed using good refrigeration installation and design practices.

Loading...

Loading...