A DJ & DG MANUAL

28 of 34 May 12 R2

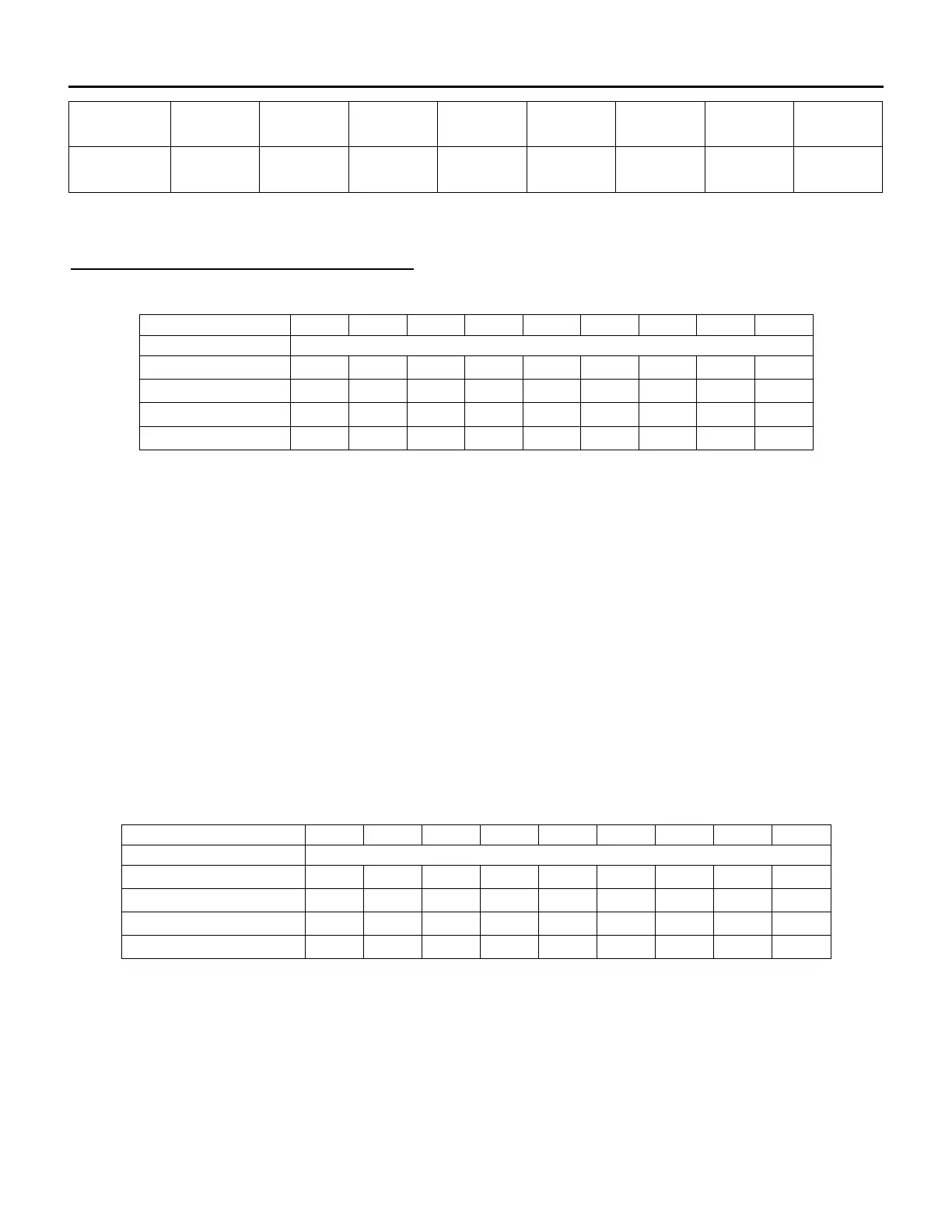

Shaft Dia.

3/4"

(19mm)

1"

(25mm)

1 3/16"

(30mm)

1 7/16"

(37mm)

1 11/16"

(43mm)

1 15/16"

(49mm)

2 7/16"

(62mm)

2 15/16"

(75mm)

Grease

0.06 oz.

(1.8g)

0.12 oz.

(3.3g)

0.20 oz.

(5.6g)

0.23 oz.

(6.5g)

0.27 oz.

(7.7g)

0.36 oz.

(10.3g)

0.53 oz.

(14.9g)

1.00 oz.

(31.0g)

For additional information refer to the fan and/or bearing manufacturers’ literature.

LUBRICATION OF DODGE FAN BEARINGS

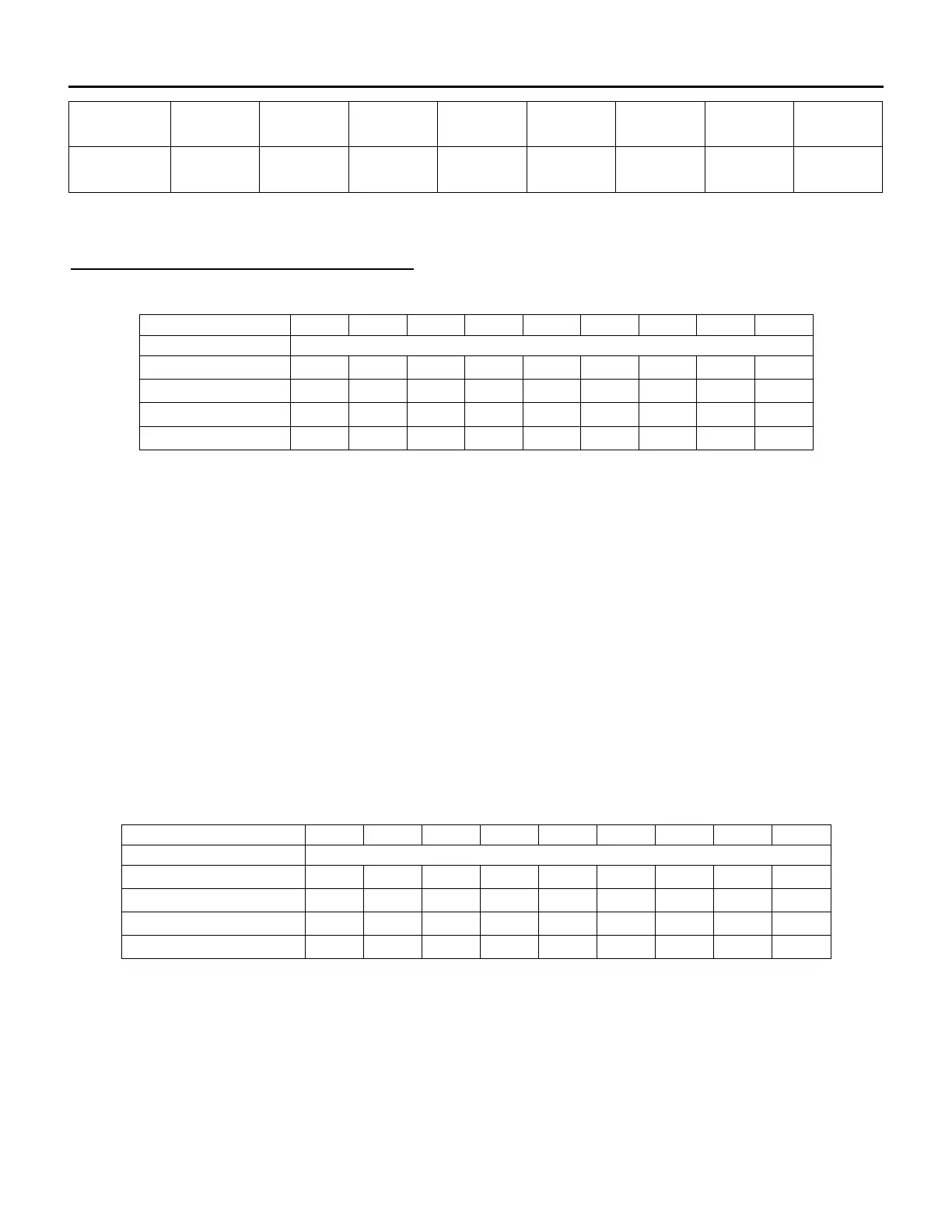

Suggested Re-lubrication Schedule (Months)* for Dodge Ball Bearing Pillow Block

Speed (RPM) 500 1000 1500 2000 2500 3000 3500 4000 4500

Shaft DIA.

½” - 1

1

/

16”

6 6 5 3 3 2 2 2 1

1

15

/

16

” – 2

7

/

16

”

6 5 4 2 2 1 1 1 1

2

11

/

16

” – 2

5

/

16

”

5 4 3 2 1 1 1

3

7

/

16

” – 3

15

/

16

”

4 3 2 1 1

* Suggested initial greasing interval. . If safety permits, re-lubricate while running until some purging

occurs at seals. Adjust lubrication frequency depending on condition of purged grease. Hours of

operation, temperature and surrounding conditions will affect the re-lubrication frequency required. For 24

hour operation double the lubrication frequency.

Lubricate with a multipurpose NLGI No. 2 or No. 3 ball bearing grease having rust inhibitors, antioxidant

additives and a minimum viscosity of 500 SSU at 100°F (38°C). Some examples of grease having these

properties are:

Shell Alvania RL 2

Mobil Mobilith SHC220

Exxon Ronex MP

Lubricate bearings prior to extended shutdown or storage and rotate shaft monthly to aid corrosion

protection.

Suggested Re-lubrication Schedule (Months)* for Dodge Spherical Roller Bearing - Solid Pillow

Block

Speed (RPM) 500 1000 1500 2000 2500 3000 3500 4000 4500

Shaft DIA.

1

3

/

16

” – 1

7

/

16”

6 4 4 2 1 1 1 1

1

/

2

1

11

/

16

” – 2

3

/

16

”

4 2 1

1

/

2

1

1

/

2

1

/

2

1

/

2

1

/

2

1

/

2

2

7

/

16

” – 3

7

/

16

”

3 1

1

/

2

1

1

/

2

1

/

2

1

/

4

1

/

4

3

15

/

16

” – 4

15

/

16

”

2

1

/

2

1

1

/

2

1

/

4

* Suggested initial greasing interval. If safety permits, re-lubricate while running until some purging occurs

at seals. Adjust lubrication frequency depending on condition of purged grease. Hours of operation,

temperature and surrounding conditions will affect the re-lubrication frequency required. For 24 hour

operation double the lubrication frequency.

Lubricate with a multipurpose roller bearing NLGI No. 2 having rust inhibitors and antioxidant additives, and

a minimum oil viscosity of 500 SSU at 100°F. Some examples of grease having these properties are:

Loading...

Loading...