A DJ & DG MANUAL

30 of 34 May 12 R2

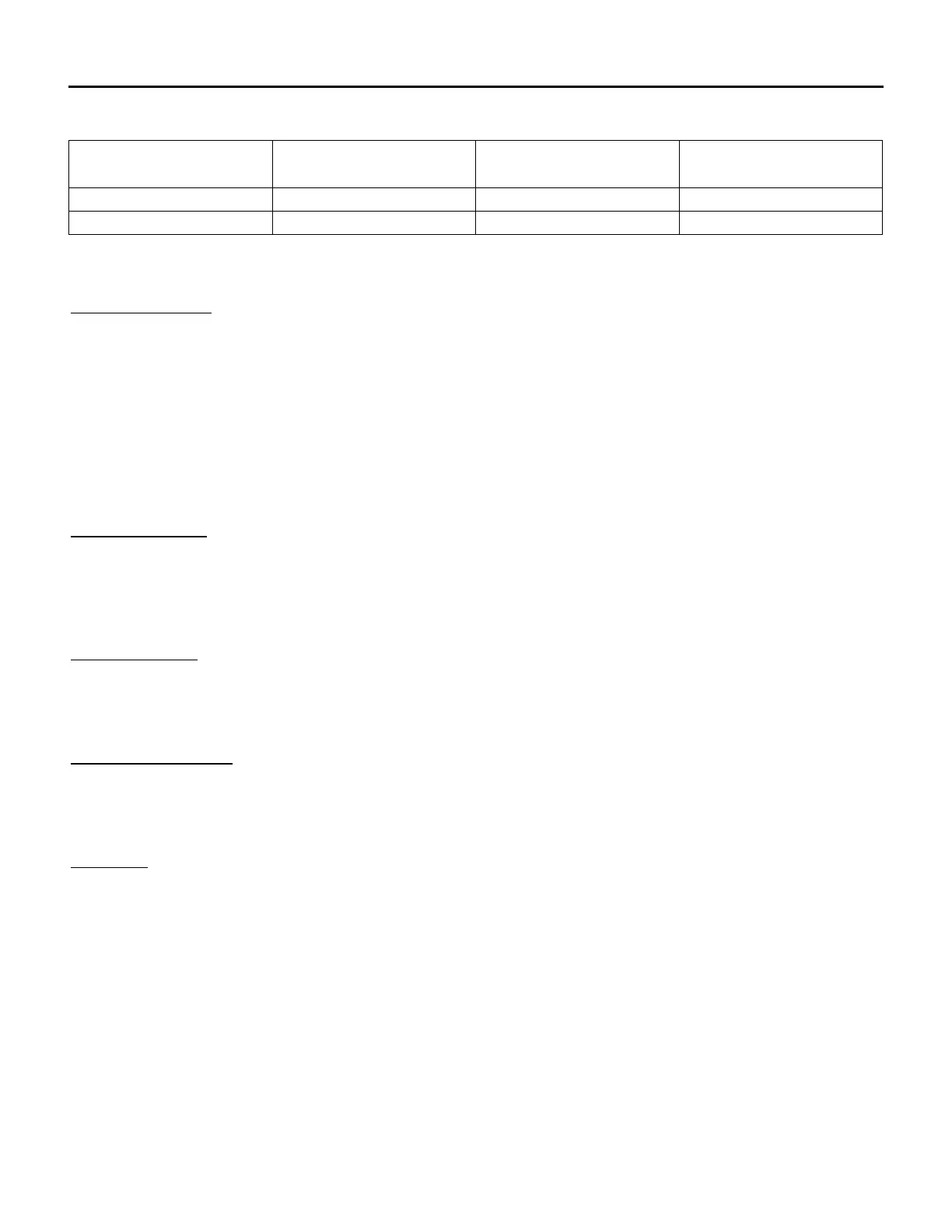

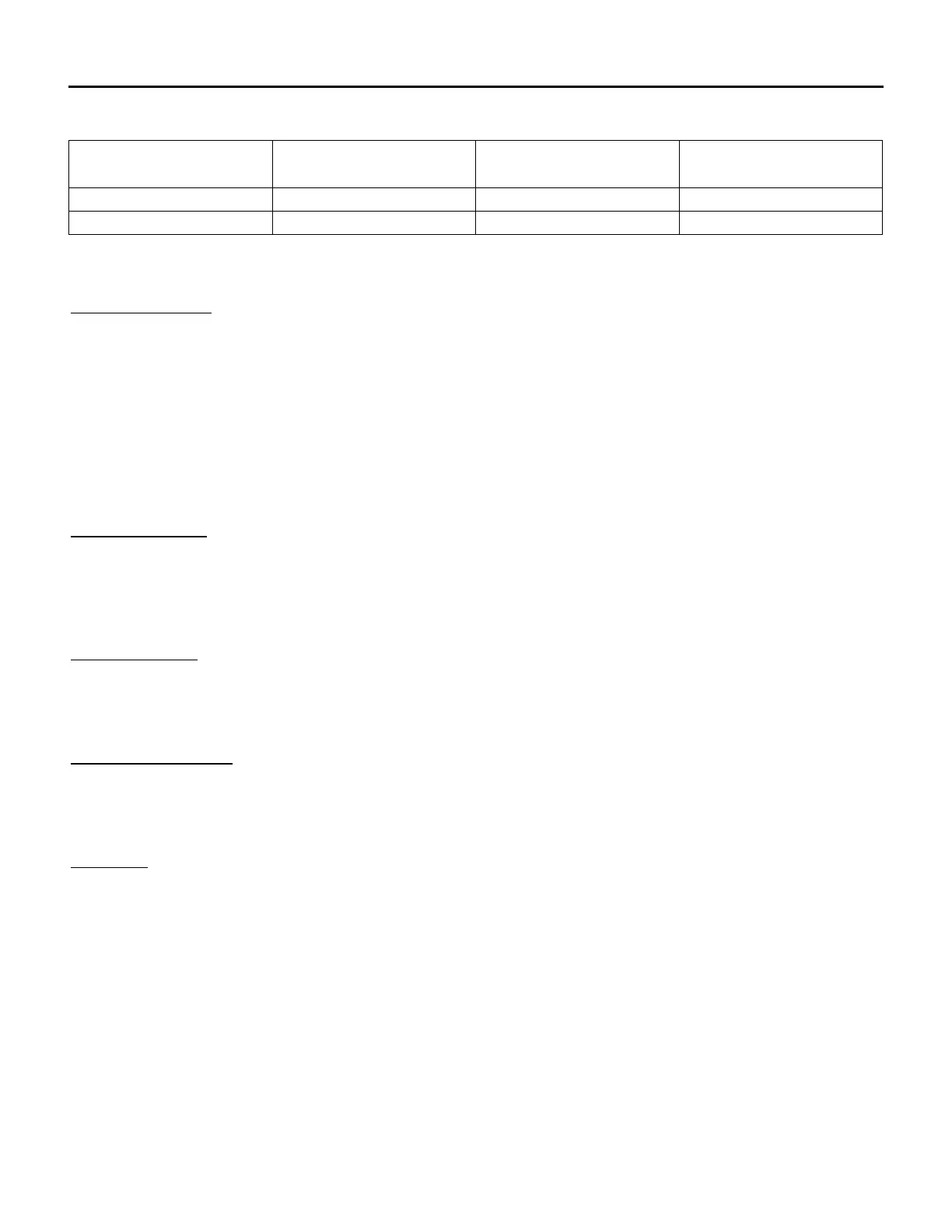

RECOMMENDED MOTOR LUBRICATION INTERVALS

Hours Service

Per Day

Up to 7.5 HP

Up to 5.6 kW

10 to 40 HP

7.5 to 29.8 kW

Over 40 HP

Over 29.8 kW

Less than 12

5 Years 3 Years 1.5 Years

More than 12

2 Years 1 Year 9 Months

NOTE: Motors that run in severe conditions should be greased as specified by the motor manufacturer.

GAS MANIFOLD

It is recommended that at least once each year the safety devices should be checked. Follow operational

check at detailed in this manual.

The Safety Shut Off Valves must be tested on at least an annual basis or as per the manufacturer’s

recommendations which ever is less.

Regulators with vent terminals must have yearly cleaning of the screen.

GAS BURNERS

It is recommended that the burner be inspected once each year. Remove any scale that may have

accumulated on the burner plates. Ensure that the holes on the burner plates and gas orifices are

completely clear of foreign material. All casting orifices on straight burners are #42.

OIL BURNERS

It is recommended that the oil burner be inspected and cleaned at least once each year. Refer to the

supplemental information bulletin from the burner manufacturer included with the unit.

VENT TERMINALS

The vent terminal should be checked and cleaned every fall. If the terminal is found to have accumulations

of leaves or other debris, clean more often as necessary.

FILTERS

Filter-changing intervals can be based on the pressure drop across the filter or by calendar scheduling or

visual inspection. Scheduled intervals should be between one and six months, depending on the pollutant

loading from indoor and outdoor air. More-frequent changes may be required during the economizer

season.

Units that operate with high levels of outside air should have filters removed (or moved to winter

filter location if available) during the winter months in areas that have heavy frost or snow.

Plugged or excessively dirty filters can cause damage to the equipment. See submittal record for filter

quantities, sizes and types. Use same size and type for replacement.

A. High Velocity Permanent:

It is important that the filters be checked and cleaned regularly during the period immediately

Loading...

Loading...