A DJ & DG MANUAL

27 of 34 May 12 R2

m CAUTION: Excessive belt tension is the most frequent cause of belt wear, bearing wear and noise.

SET SCREWS

Check set screws on fan wheel, fan bearings, fan and motor pulleys for looseness on the shaft. Tighten

where required. IT IS IMPORTANT TO PERFORM THIS CHECK BEFORE INITIAL START-UP, AFTER A

RUN-IN PERIOD OF 2 WEEKS AND THEN ON 4 MONTH INTERVALS.

m CAUTION: OVERTIGHTENING SET SCREWS CAN DAMAGE BEARINGS.

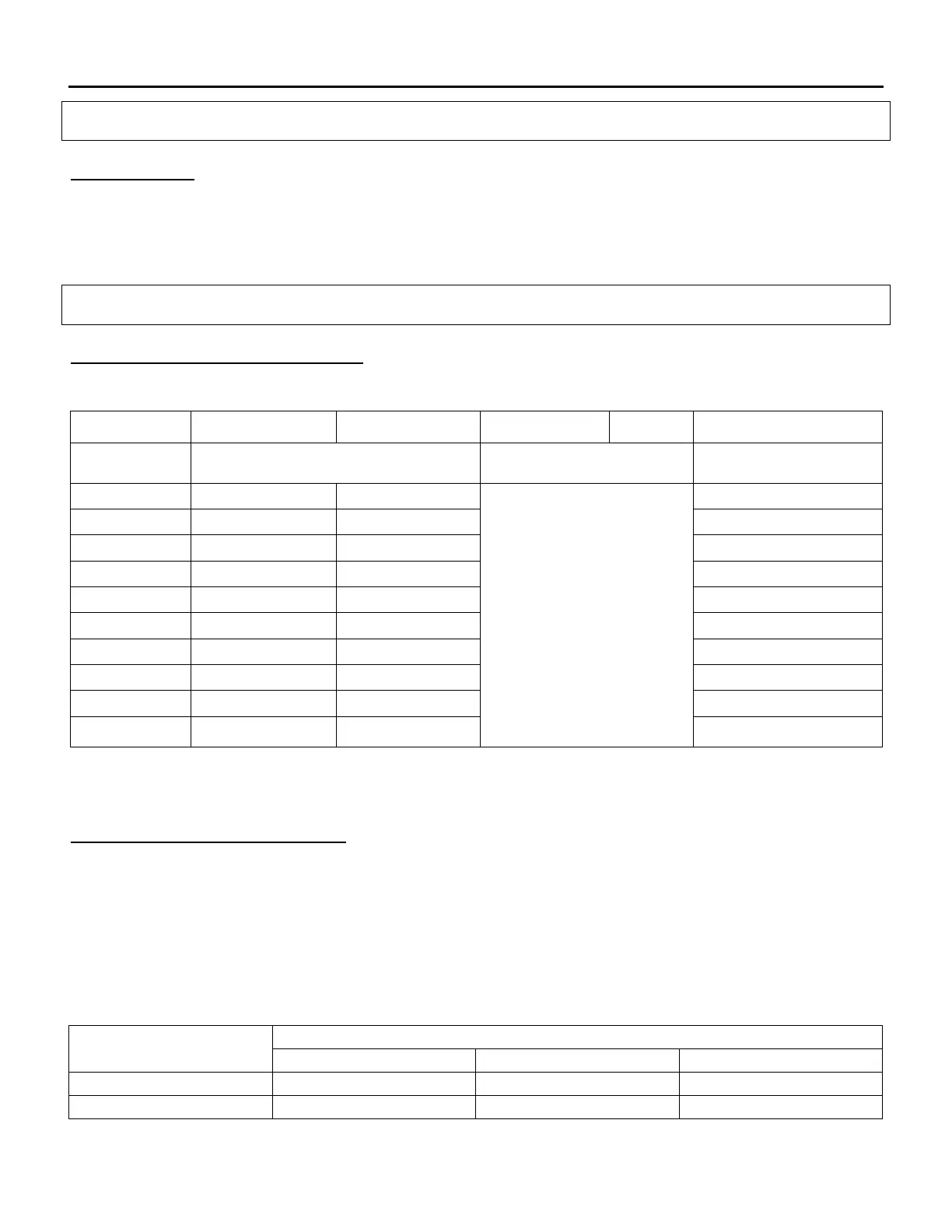

BEARING SETSCREW TORQUES

Shaft diameter

NTN KOYO NTN KOYO DODGE

Type

UC SERIES

(set screw)

UK SERIES

(adapter sleeve locknut)

SC 203-215 SERIES

3/4" (19mm) 35 in-lb (3.9 Nm) 35 in-lb (4.0 Nm) 66 - 80 in-lb (7.5 - 9 Nm)

1" (25mm) 35 in-lb (3.9 Nm) 35 in-lb (4.0 Nm) 126 - 156 in-lb (14 -18 Nm)

1 3/16" (30mm) 43 in-lb (4.9 Nm) 35 in-lb (4.0 Nm) 126 - 156 in-lb (14 -18 Nm)

1 7/16" (37mm) 51 in-lb (5.8 Nm) 75 in-lb (8.5 Nm) 126 - 156 in-lb (14 -18 Nm)

1 11/16"(43mm) 69 in-lb (7.8 Nm) 75 in-lb (8.5 Nm) 228 - 272 in-lb (26 -31 Nm)

1 15/16"(49mm) 69 in-lb (7.8 Nm) 155 in-lb (17.5 Nm) 228 - 272 in-lb (26 -31 Nm)

2 3/16"(56mm) 87 in-lb (9.8 Nm) 155 in-lb (17.5 Nm) 228 - 272 in-lb (26 -31 Nm)

2 7/16"(62mm) 147 in-lb (16.6 Nm) 155 in-lb (17.5 Nm) 228 - 272 in-lb (26 -31 Nm)

2 11/16"(68mm) 173 in-lb (19.6 Nm) 248 in-lb (28.0 Nm) 228 - 272 in-lb (26 -31 Nm)

2 15/16"(75mm) 173 in-lb (19.6 Nm) 248 in-lb (28.0 Nm)

Install the washer and lock nut;

tighten the nut fully by hand.

Apply a punch or screw driver

into the notch of the nut and

tap it with a hammer. Stop

tapping after the nut has turned

60° to 90°.

Do not strike the seal.

Bend the tab on the rim of the

washer, which is in line with the

notch of the nut.

If a tab does no line up with a

notch, tighten the nut further.

DO NOT BACK THE NUT

OFF.

228 - 272 in-lb (26 -31 Nm)

Refer to bearing manufacturers’ literature for all other types of bearings.

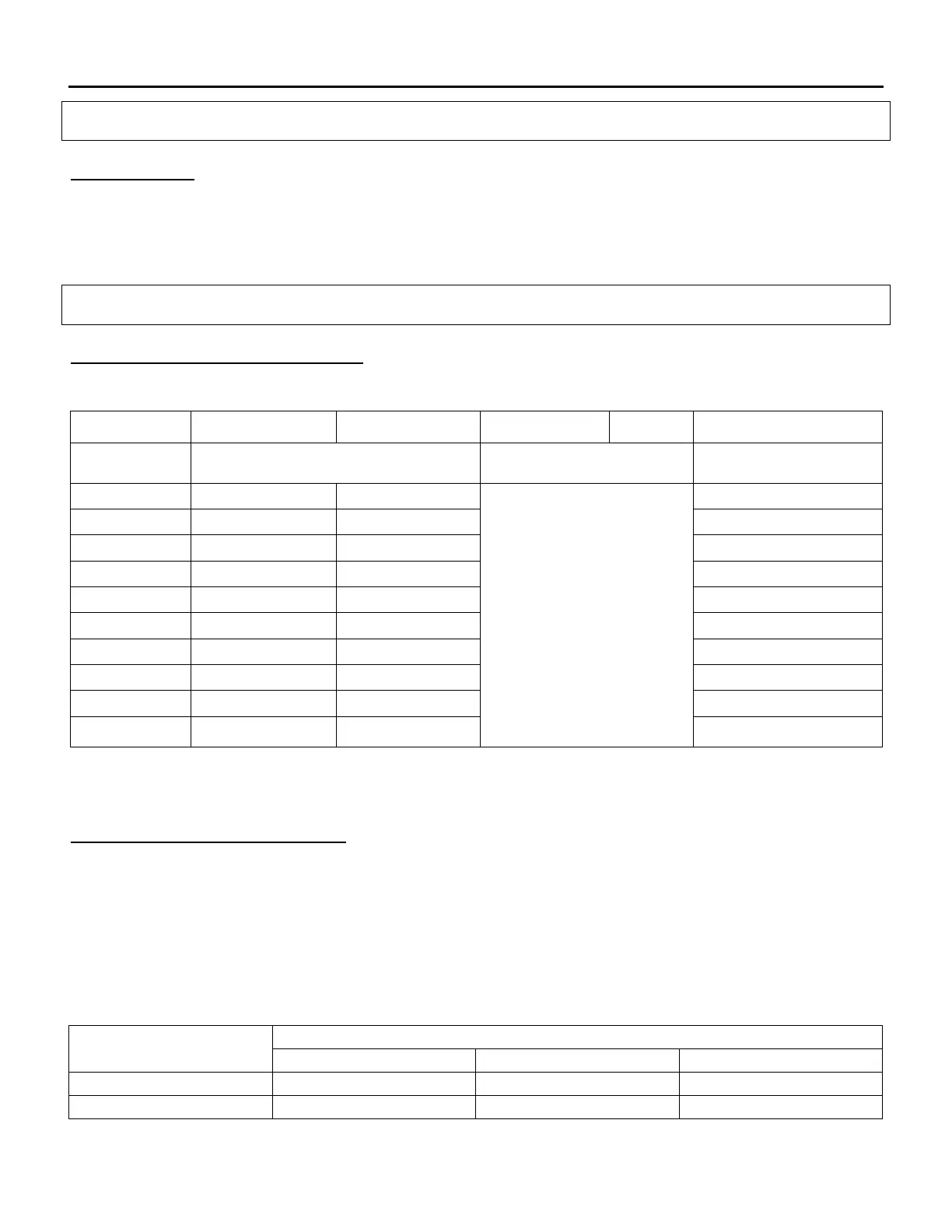

LUBRICATION OF FAN BEARINGS

Some fans have permanently lubricated sealed ball bearings which should not require lubrication. These

bearings are factory packed 30 to 50% full. Bearings that require lubrication should be greased while

the bearing is rotating slowly, with the following quantities of a lithium base lubricant. DO NOT

OVERGREASE. DO NOT USE NON-LITHIUM BASED GREASE.

Extended lubrication lines may be provided. Tubing is not factory filled.

RECOMMENDATIONS FOR BALL BEARINGS

Re-Greasing Interval

Bearing Temperature

° F (°C)

Clean Dusty Dusty & Wet

Under 120 (50)

2 ½ Years Yearly 4 Months

Under 158 (70)

Yearly 4 Months 1 Month

Loading...

Loading...