A DJ & DG MANUAL

26 of 34 May 12 R2

To provide a maintenance history, It is recommended that the owner have a maintenance file for each unit.

The following maintenance instructions are to be carried out each spring and fall or as otherwise

indicated by qualified service personnel.

Caution:

m

c

Label all wires prior to removal when servicing controls or critical

components. Wiring errors can cause improper and dangerous operation.

Verify proper operation after servicing.

ELECTRICAL

1. Check all wiring for loose connections.

2. Check voltage at unit (while in operation).

3. Check amperage draw against unit rating plate.

4. Where possible, all contactors should be inspected to ensure that contacts are clean and are

making good contact. If contacts are abnormally pitted or burned badly, replace contactor. Single

phasing and motor burnouts can result from bad contacts.

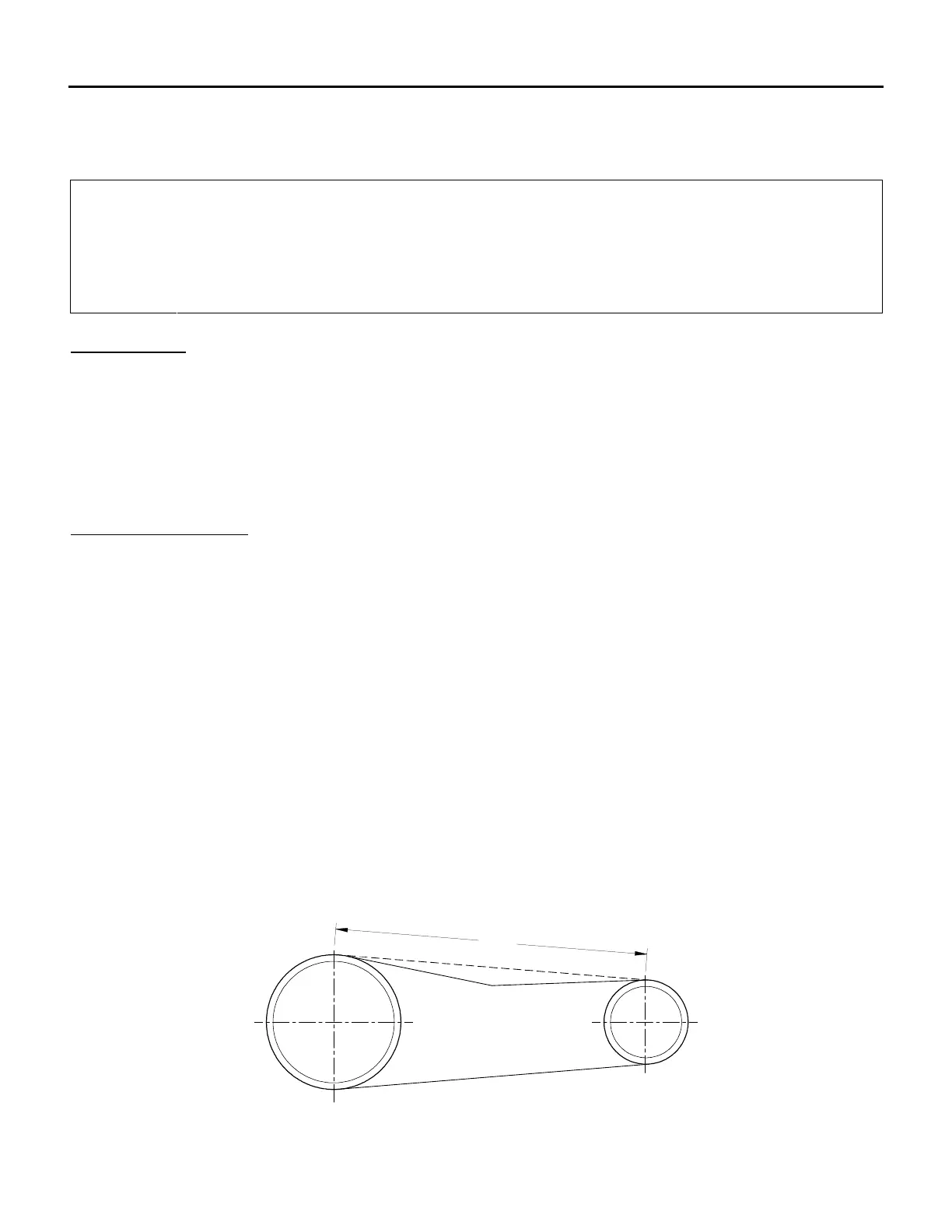

BELT ADJUSTMENT

For maximum belt and bearing life, pulley alignment and belt tension must be properly maintained. Only

replace with belts of the proper type and size.

NOTE: If belts are too tight or improperly aligned, the life expectancy of the motor(s), fan bearings and

belt(s) are reduced.

Alignment: Pulleys must be aligned to within 1/16” per foot (1mm per 760mm) of span.

FOR FANS EQUIPPED WITH SPIDER BRACKETS:

A properly adjusted V-belt rides the inside of the pulley faces. Because the sides of the belt wedge in the

pulleys, the V-belt does not have to be extremely tight. It should be as loose as possible without slipping in

the pulley grooves.

Belt deflection: 3/4 “ (19mm) for each foot (300mm) of span between the pulleys.

FOR FANS EQUIPPED WITH PILLOW BLOCK BEARINGS:

Belt Deflection: Allow 1/64” (0.4mm) of deflection for each 1” (25.4 mm) of span length.

DEFLECTION

SPAN

Loading...

Loading...