EVR AUTOMATIC RECLOSER http://www.entecene.co.kr

33

ENHANCED TECHNOLOGY

5.3.4. High voltage connection

Before installation, all terminals and connectors should be cleaned and prepared to be able to keep

low resistance connection.

Please refer to bushing assembly drawings shown in Figure 5-7.

Porcelain Bushing

The high voltage bare conductor should be placed in the hole of the universal clamp and fastened

with nut upto tensile torque of 400kg-cm.

Polymer Bushing

For the polymer mold type of bushing, the stud clamp type made of anti-corrosive bronze is placed

on the top of bushing.

Insert HV cable directly into the center of stud clamps placed on the top of polymer bushing, and

fasten four joint bolts evenly with tensile torque of 150kg-cm.

5.3.5 Bushing

Depending on request, Bushing of Recloser is made of either porcelain or polymer.

Bushing and bushing housing is completely assembled and tested at the factory before dispatching.

Simply users connect the high voltage cable onto High Voltage Terminal at the top of Bushing.

Porcelain Bushing

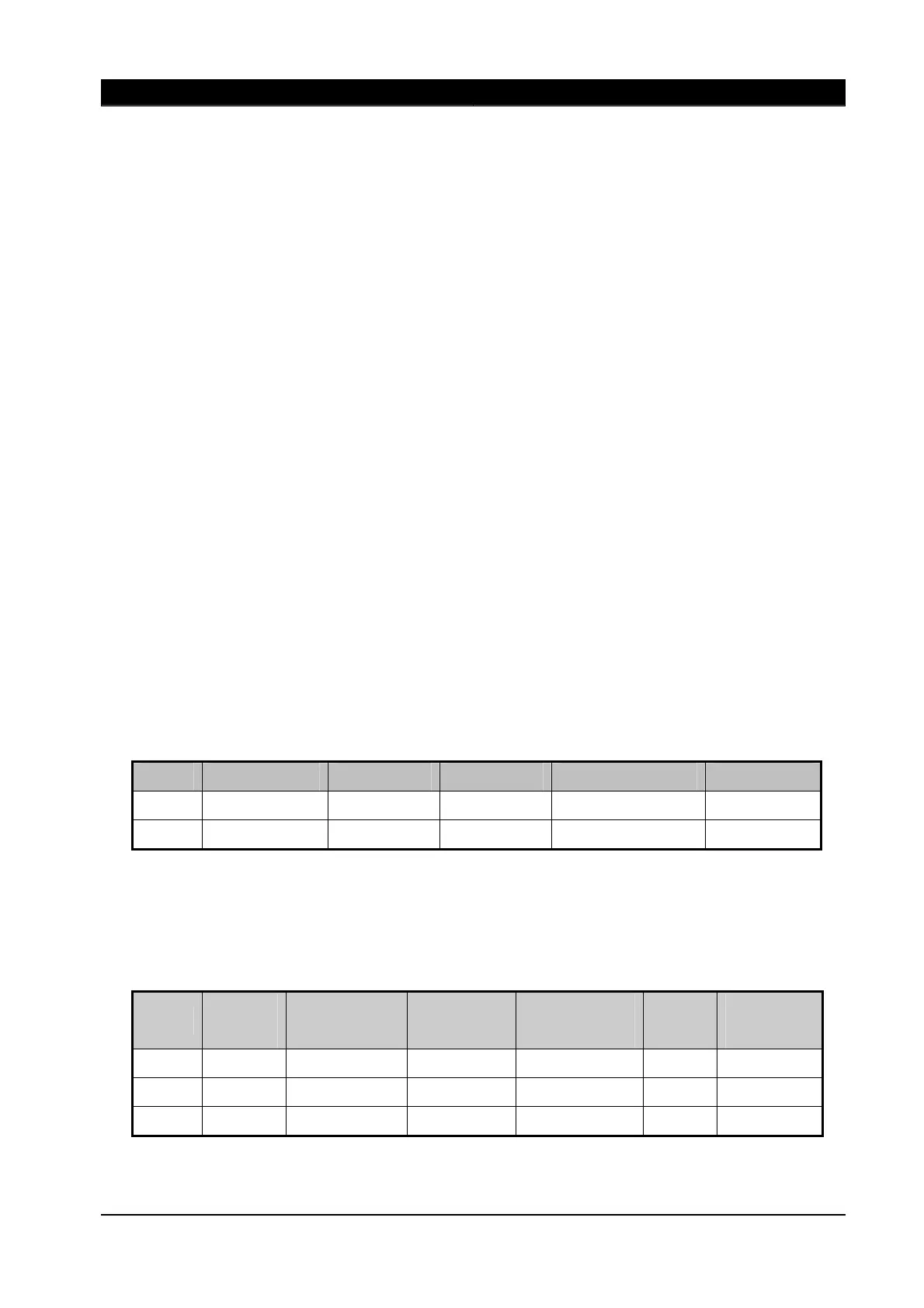

Table 5-1. Porcelain Bushing

Type Creepage distance Arcing distance Terminal type Applicable cable size Rating (Amps)

EVR 1 440 m/m 220m/m Universal clamp 24 m/m (diameter) 630

EVR 2 750 m/m 300 m/m Universal clamp 24 m/m (diameter) 630

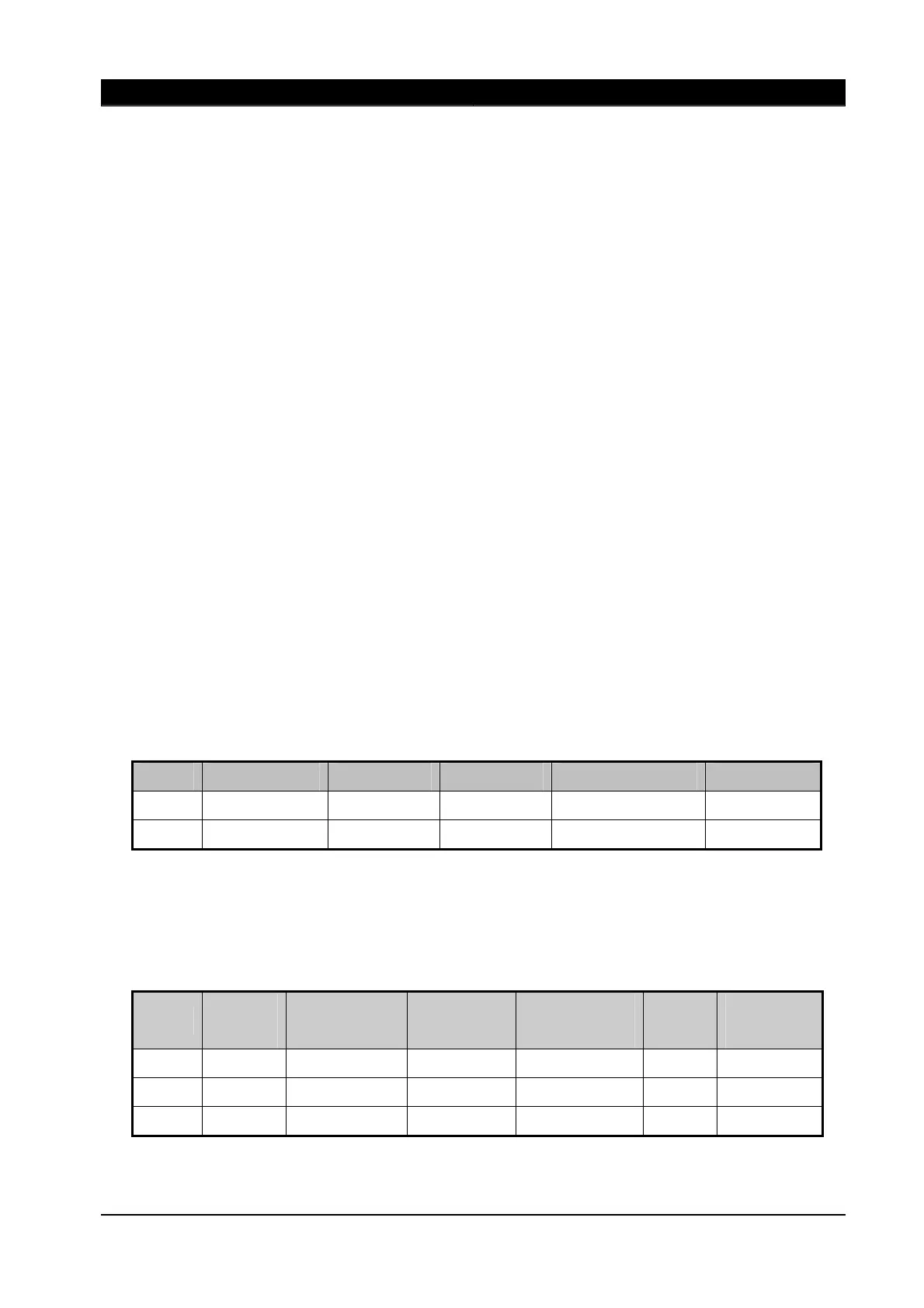

Polymer Bushing

Type of Bushing is Separable connector type standardized by IEEE 386, the material of Insulation

Housing can be made of either E.P.D.M or Silicone.

Table 5-2. Polymer Bushing

Type

Creepage

distance

Arcing Distance Terminal type

Applicable

cable size

Rating

(Amps)

Housing

Material

EVR1 520 m/m 220 m/m STUD clamp 25 m/m(Max.dia.) 630 EPDM/Silicone

EVR2 860 m/m 330 m/m STUD clamp 25 m/m(Max.dia.) 630 EPDM/Silicone

EVR3 1100 m/m 400 m/m STUD clamp 30 m/m(Max.dia.) 800 EPDM/Silicone

Loading...

Loading...