L120 Revision A

Disassembly/Reassembly Detailed Disassembly/Reassembly Procedure for each Part/Unit 35

Confidential

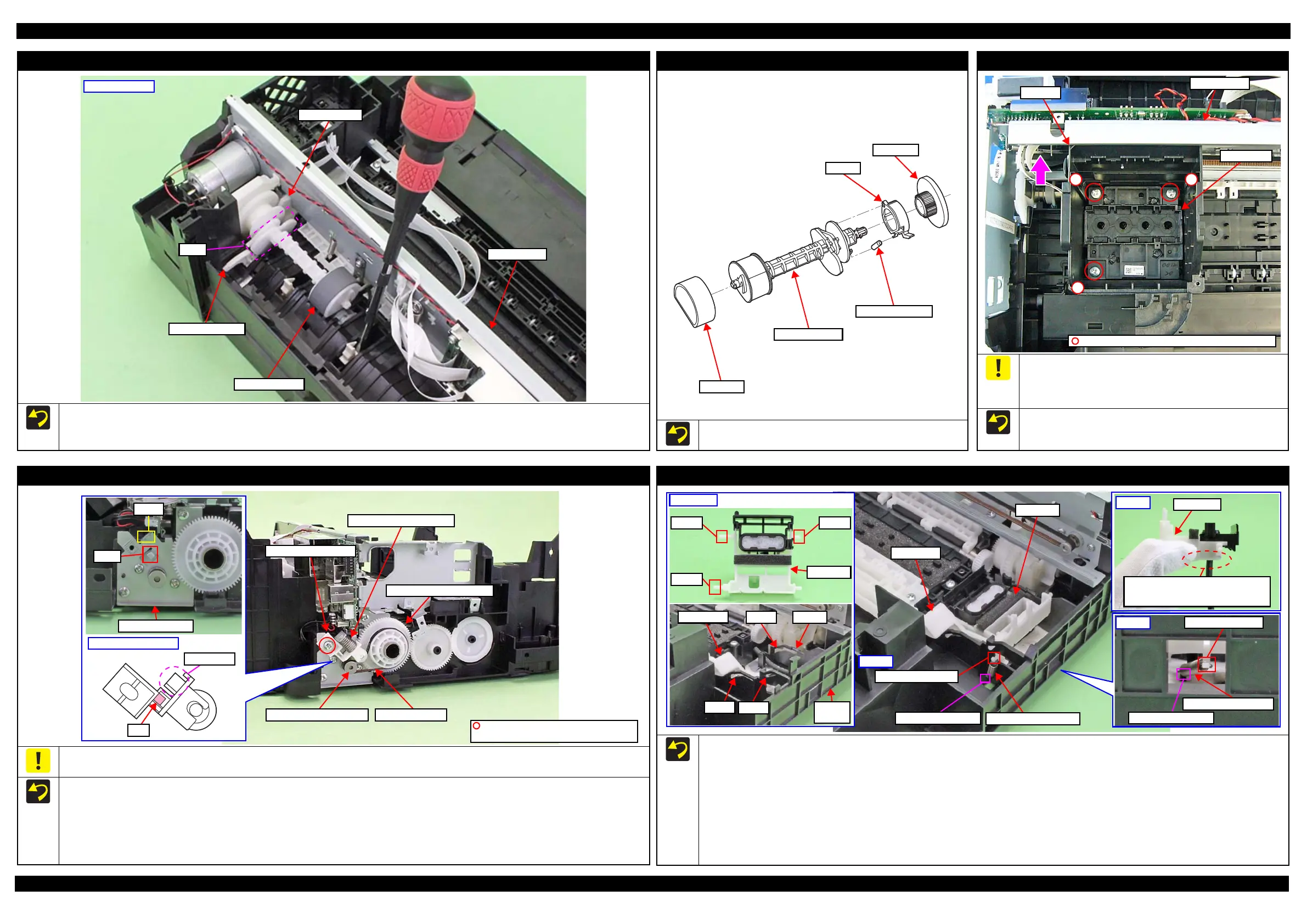

LD Roller Assy (1)

Install the LD Roller Assy with the following condition in order to avoid the Change Lever and Paper Back Lever.

Using a screw driver or the like, hold the Paper Back Lever to the rear as shown above not to let it touch the LD Roller Assy.

Push the Change Lever to the front to keep it in the hole of the Main Frame.

LD Roller Assy

Paper Back Lever

Change Lever

Cam

Main Frame

Rear of printer

LD Roller Assy (2)

If each part shown above comes off when removing the LD Roller

Assy, attach them back in place as shown in the figure above.

LD Roller

LD Roller Shaft

Extension Spring

Clutch

Spur gear

Printhead

When removing/replacing the Printhead, do not apply excess

downward force when tightening the screws. Otherwise, the Main

Frame may be deformed by the applied perpendicular force when

screwing, and the print quality may be affected adversely.

Tighten the screws of the Printhead in the order indicated in the

figure above while pressing the Printhead in the direction of the

arrow.

2 1

3

Main Frame

Printhead

CR Unit

C.B.P-TITE SCREW 3x10 F/ZN-3C (7 ± 1 kgf·cm)

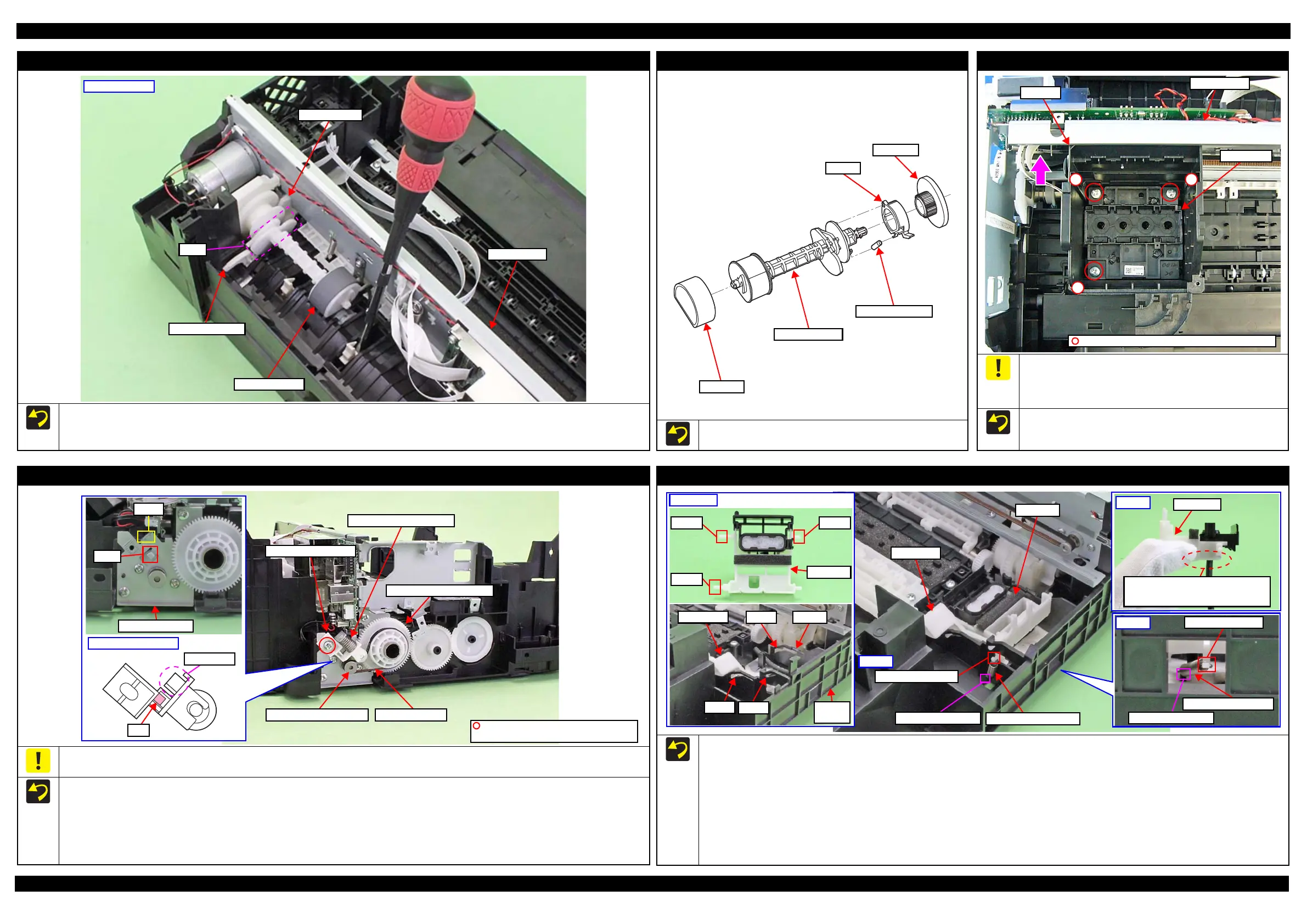

PF Driven Pulley Assy / PF Timing Belt

Do not hold the PF Driven Pulley Assy when securing it with the screw in order to prevent applying improper tension to the PF Timing Belt.

When installing the PF Driven Pulley Assy, follow the procedure below.

1. Align the rib of the PF Driven Pulley Assy with the hook of the PF Motor Frame, and install the PF Driven Pulley Assy.

2. Attach the Compression Spring 5.07 to the protrusion of the PF Driven Pulley Assy and the dowel of the PF Motor Frame.

3. Attach the PF Timing Belt in the order of the pinion gear of the PF Motor, PF Driven Pulley and Combination Gear 29.2,42.

4. Rotate the Combination Gear 29.2,42 clockwise three times to confirm the PF Timing Belt is correctly attached, and then secure the PF Driven

Pulley Assy with the screw and washer to the PF Motor Frame.

Rib

PF Driven Pulley Assy

Protrusion

Compression Spring 5.07

Combination Gear 29.2,42

PF Timing Belt

PF Driven Pulley Assy

C.B.S-TITE(P2) SCREW 3x6 F/ZN-3C

P.W. 3.4x0.43x7 (7 ± 1 kgf·cm)

Cap Lever/Cap Assy

When installing the Cap Lever/Cap Assy, follow the procedure below.

1. Attach the Cap Lever to the Frame Base, and attach one end of the Extension Spring 0.65 to the hook of the Frame Base.

2. Connect the tube of the Pump Unit to the joint on the bottom of the Cap Assy. Then, viewing from the side, confirm the marking (10

1 mm

from the tube end) on the tube is covered by the Cap Slider.

3. Insert the shaft A of the Cap Assy through the hole of the Cap Lever to the hole A of the Frame Base.

4. Insert the shaft B of the Cap Assy through the cutout of the Frame Base and to the hole B of the Frame Base.

5. Insert the shaft C of the Cap Assy to the hole C of the Frame Base.

6. Using a “spring hook jig” (p 16), attach the other end of the Extension Spring 0.65 to the hook of the Cap Assy.

7. Attach the Extension Spring 1.329 to the hooks of the Cap Lever and Frame Base.

Cap Lever

Extension Spring 1.329

Cap Assy

Extension Spring 0.65

Hook of Cap Assy

Hook of Frame Base

Step 6

Shaft BShaft A

Shaft C

Cap Assy

Step 2

Make sure the marking (10 ± 1 mm

from the tube end) on the tube cannot

be seen when viewed from the side.

Cap Slider

CutoutHole B

Cap Lever

Frame

Base

Hole A

Hole C

Step 1, 3-5

Hook of Frame Base

Hook of Cap Lever

Step 7

Loading...

Loading...