Epson Stylus NX510/515/SX510W/515W/TX550W/NX415/SX410/415/TX410/419/NX215/SX210/215/TX210/213/219/ME OFFICE 510 Revision A

ADJUSTMENT Adjustment Items and Overview 162

Confidential

5.1 Adjustment Items and Overview

This chapter describes adjustments required after the disassembly/reassembly of the

printer.

5.1.1 Servicing Adjustment Item List

The adjustment items of this product are as follows.

In this chapter, the product names are called as follows:

For information on how to carry out the adjustments and

media required for the adjustments, see the instructions

displayed by the Adjustment Program.

Notation Product name

NX510 series Epson Stylus NX510/NX515/SX510W/SX515W/TX550W

SX410 series Epson Stylus NX415/SX410/SX415/TX410/TX419

SX210 series

Epson Stylus NX215/SX210/SX215/TX210/TX213/

TX219/ME OFFICE 510

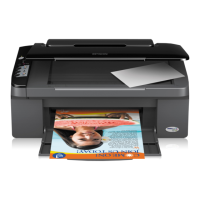

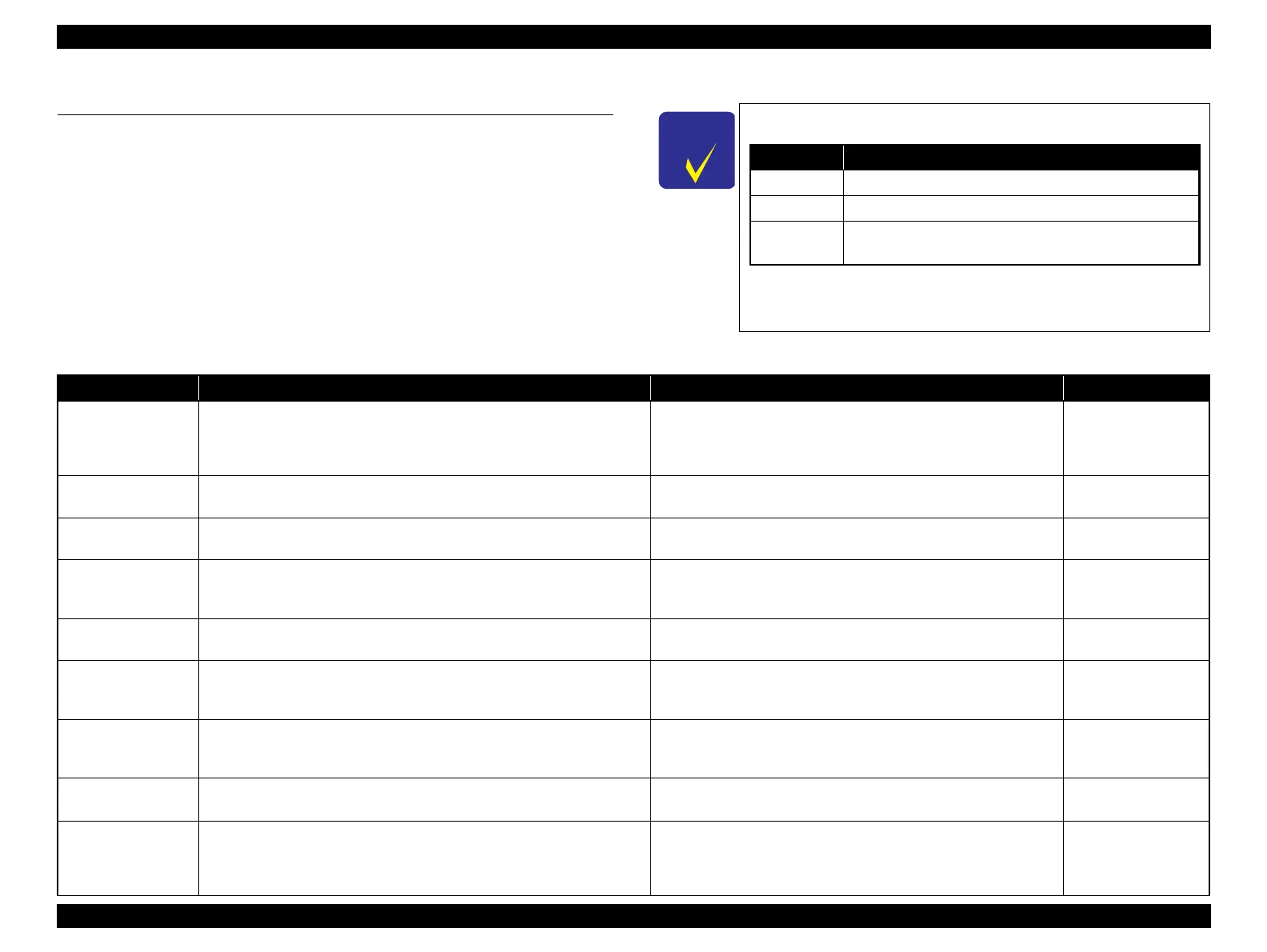

Table 5-1. Adjustment Items

Adjustment Item Purpose Method Outline Tool

EEPROM data copy

When the main board needs to be replaced, use this to copy adjustment

values stored on the old main board to the new board. If this copy is

completed successfully, all the other adjustments required after replacing the

main board are no longer be necessary.

Readout the EEPROM data from the main board before removing it.

Then replace the board with a new one, and load the EEPROM data to

the new board.

• Adjustment Program

Initial setting

This must be carried out after replacing the main board to apply settings for

the target market.

Select the target market. The selected market settings are

automatically written to the main board.

• Adjustment Program

USB ID input

This sets a USB ID of the printer. A computer identifies the printer by the ID

when multiple same models are connected via a USB hub.

Enter the product serial number of the printer. The ID is automatically

generated and written to the main board.

• Adjustment Program

Head ID input

This must be carried out after replacing the Printhead in order to enter the

new Printhead ID (Head ID) that reduces variation between Printheads.

Enter the ID printed on the Head QR code label attached on the

Printhead. The correction values are automatically written to the main

board.

• Adjustment Program

MAC address

read/write

*1

When the Main board needs to be replaced use this menu to write necessary

information onto the new board.

See “ 5.2.8 MAC Address Setting (NX510 series only) (p173) ”for the

detailed procedure.

• Adjustment Program

• USB Cable

TOP margin

adjustment

This corrects top margin of printout. A top margin adjustment pattern is printed. Examine the lines printed

near the top edge of the printout, and enter the value for the line that

is exactly 3 mm away from the top edge.

• Adjustment Program

•Ruler

First dot position

adjustment

This corrects left margin of printout. The print start position in the carriage

moving direction is corrected by software.

A first dot adjustment pattern is printed. Examine the lines printed

near the left edge of the printout and enter the value for the line that is

exactly 5 mm away from the left edge.

• Adjustment Program

•Ruler

Head angular

adjustment

This must be carried out after replacing the Printhead in order to correct tilt

of the Printhead by software.

A head angular adjustment pattern is printed. Examine the printed

lines and enter the value for the most straight lines.

• Adjustment Program

Bi-D adjustment

This corrects print start timing in bi-directional printing to improve the print

quality.

A Bi-D adjustment pattern is printed. Black and color patterns are

printed for each of the five dot sizes (ECO, VSD1, VSD2, VSD3,

VSD4). So, there are 10 groups. Examine the patterns and enter the

value for the pattern with no gap and overlap for each mode.

• Adjustment Program

Loading...

Loading...