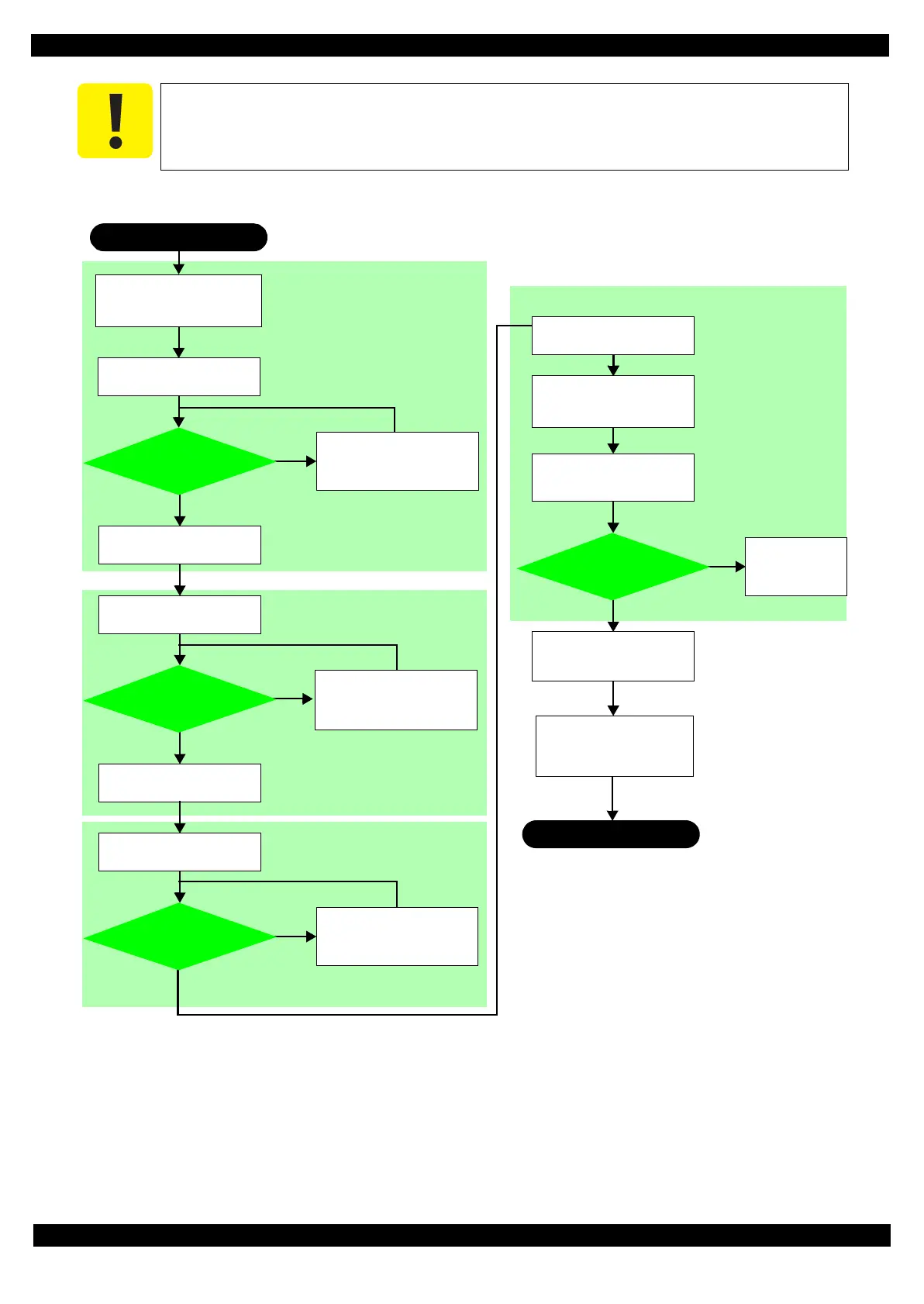

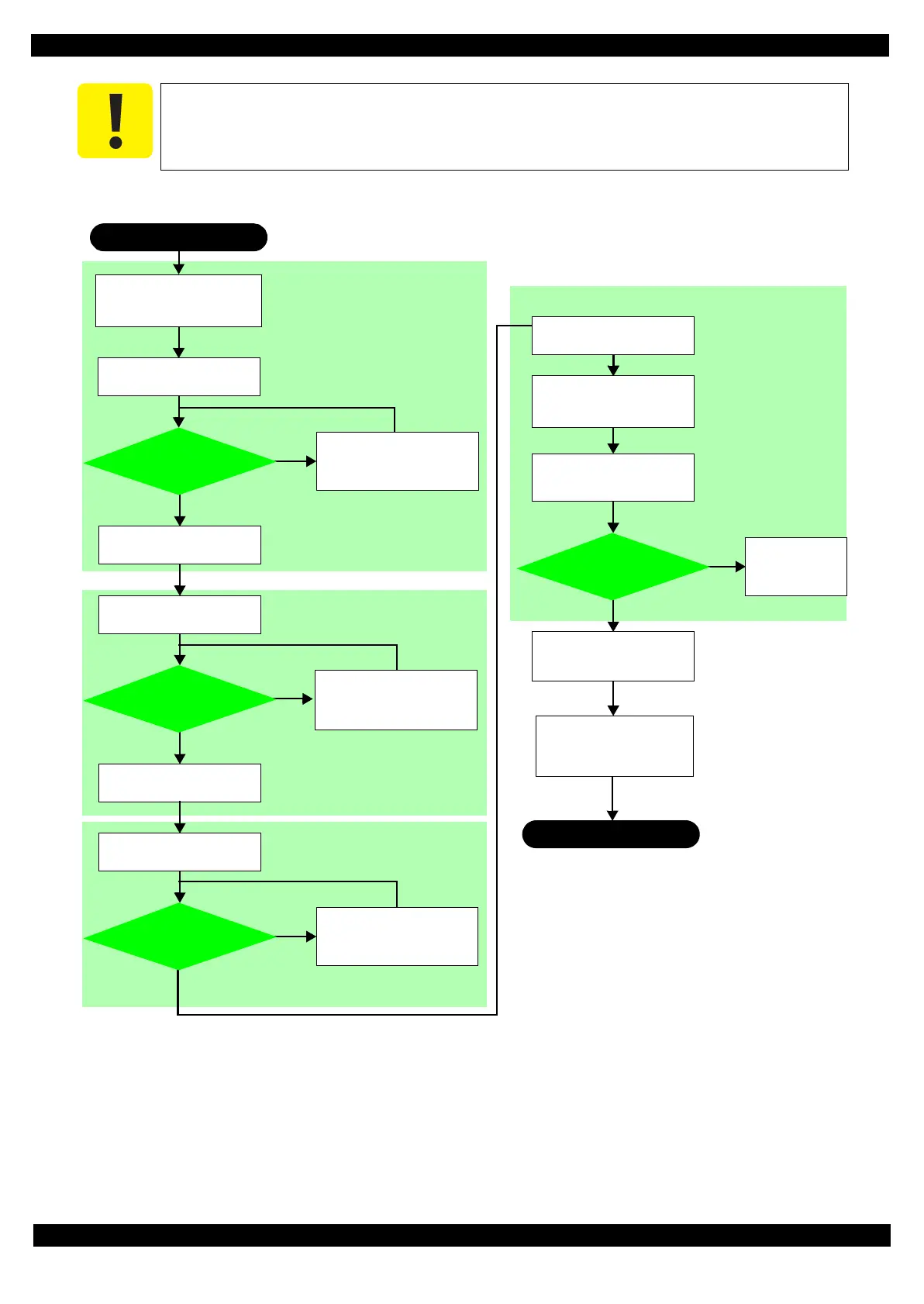

9. Follow the flowchart below to perform the PG adjustment.

Figure 3-27. PG Adjustment Flow

Frame. (See Figure 3-24 (p 72).)

START

Move the Carriage Assy to

the 0-digit side.

Yes

No

Move the Carriage Assy to

the center of the printer.

Move the Carriage Assy to

the center, and adjust one

notch for PG Cam Right to

make the PG wider.

Yes

No

Yes

No

Yes

No

Remove the PG Cam Right/

Left once, and attach them

back on the same positions

as shown in Step 1. (p 71).

Return to Step 7.

(p 73) and

perform the

adjustment again.

END

Change the thickness gauges

(x2) to 1.37 mm ones that the

teflon tape attached.

Adjusts the PG to more than

1.45 mm on the 0-digit side.

Move the Carriage Assy to

the center of the printer.

Move the Carriage Assy to

the 80-digit side.

Move the Carriage Assy to

the 0-digit side.

Move the Carriage Assy to

the center of the printer.

Change the thickness gauges

(x2) to 1.47 mm ones that

the Teflon tape attached.

Move the Carriage Assy to

the 0-digit side and to the

80-digit side.

Does the Carriage

Assy touch the

thickness gauges?

Does the Carriage

Assy touch the

thickness gauges?

Does the Carriage

Assy touch the

thickness gauges?

Does the Carriage

Assy touch the

thickness gauges?

Adjusts the PG to more than

1.45 mm on the 80-digit side.

Confirms the PG is more than

1.45 mm on the 0-digit side.

Confirms the PGs are less

than 1.55 mm on the 0-digit

side and 80-digit side.

Secure the CR Guide Frame

with the screws (x3).

(See Figure 3-22 (p 71).)

Move the Carriage Assy to

the center, and adjust one

notch for PG Cam Left to

make the PG wider.

Move the Carriage Assy to

the center, and adjust one

notch for PG Cam Right to

make the PG wider.

Loading...

Loading...