Instruction manual for installation and operation of automatic pellet burner “ERATO GP20+”

(Version : 02.02.2010 10:36) p. 36/50

considered as a result of the operating process of the pellet burner, it is possible

to arise risks as follows:

• Cauterization risks, caused by high temperatures, as a result of the

combustion process in the combustion chamber, at manual cleaning

processes of the surfaces of the burner (i.e. its combustion chamber), or

ash residue cleaning, or any unburned fuel material, smoldering on the

grate of the combustion chamber;

• Electrical shock risks at indirect contact. The burner is connected to the

power supply and its operating modules are separated in a section of its

main module, equipped with required protective and short-circuit

preventive elements. It is obligatory to perform by authorized

personal/technician the burner ground connection. It is forbidden to

remove the cover of the main unit of the burner, as well as the protective

cover of the electric motor of the fuel transport auger, by unauthorized

person.

• Fingers injuring risks at operating mode or at maintenance and cleaning

process of the burner. It is recommended to use appropriate individual

resources for self-protection;

• Suffocation risks due to flue gas uncontrolled emissions, in case when the

chimney draught is insufficient, in case that the flue gas duct (of the heat

consumer unit) is clogged, or in case that the flue gas duct is not fully

tightened and gas leaks are possible;

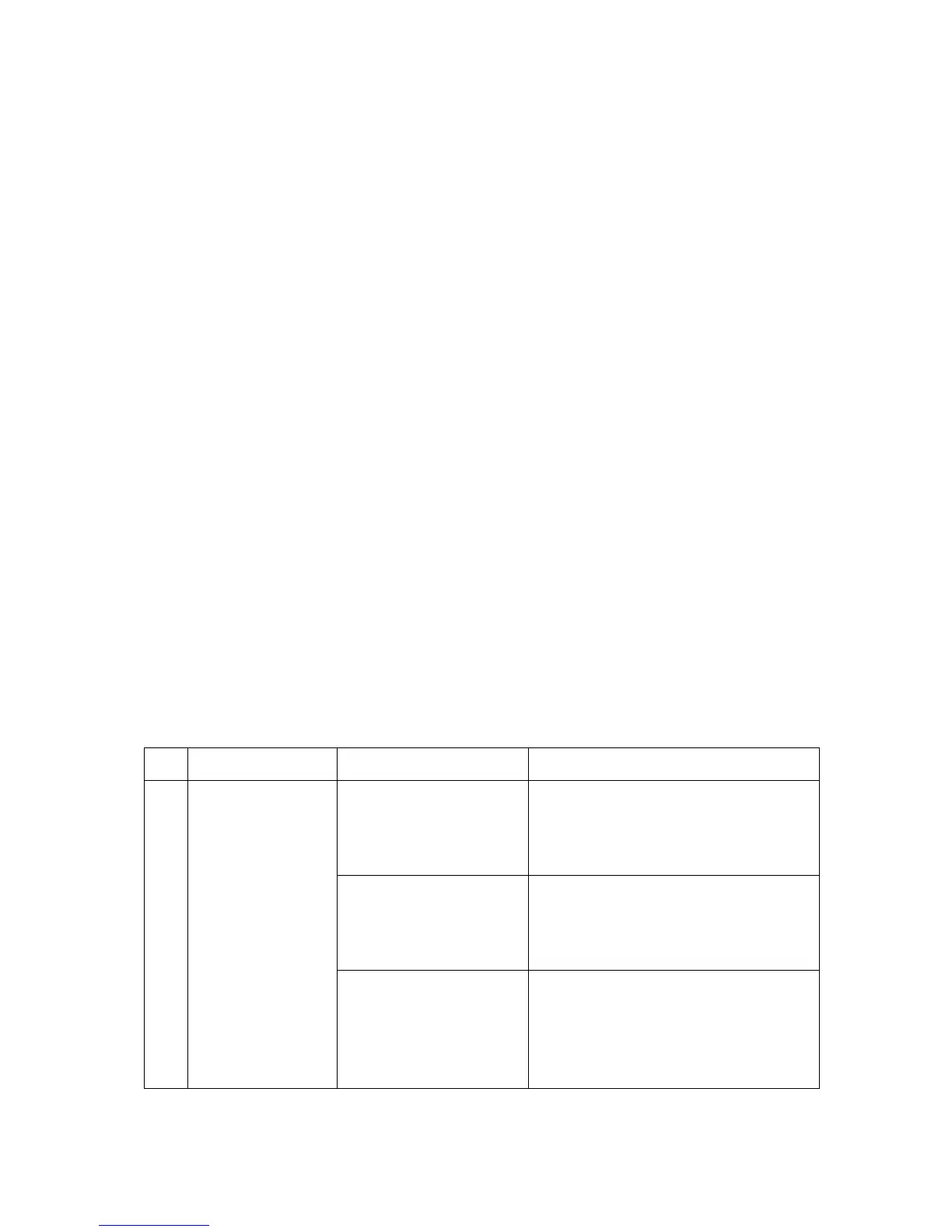

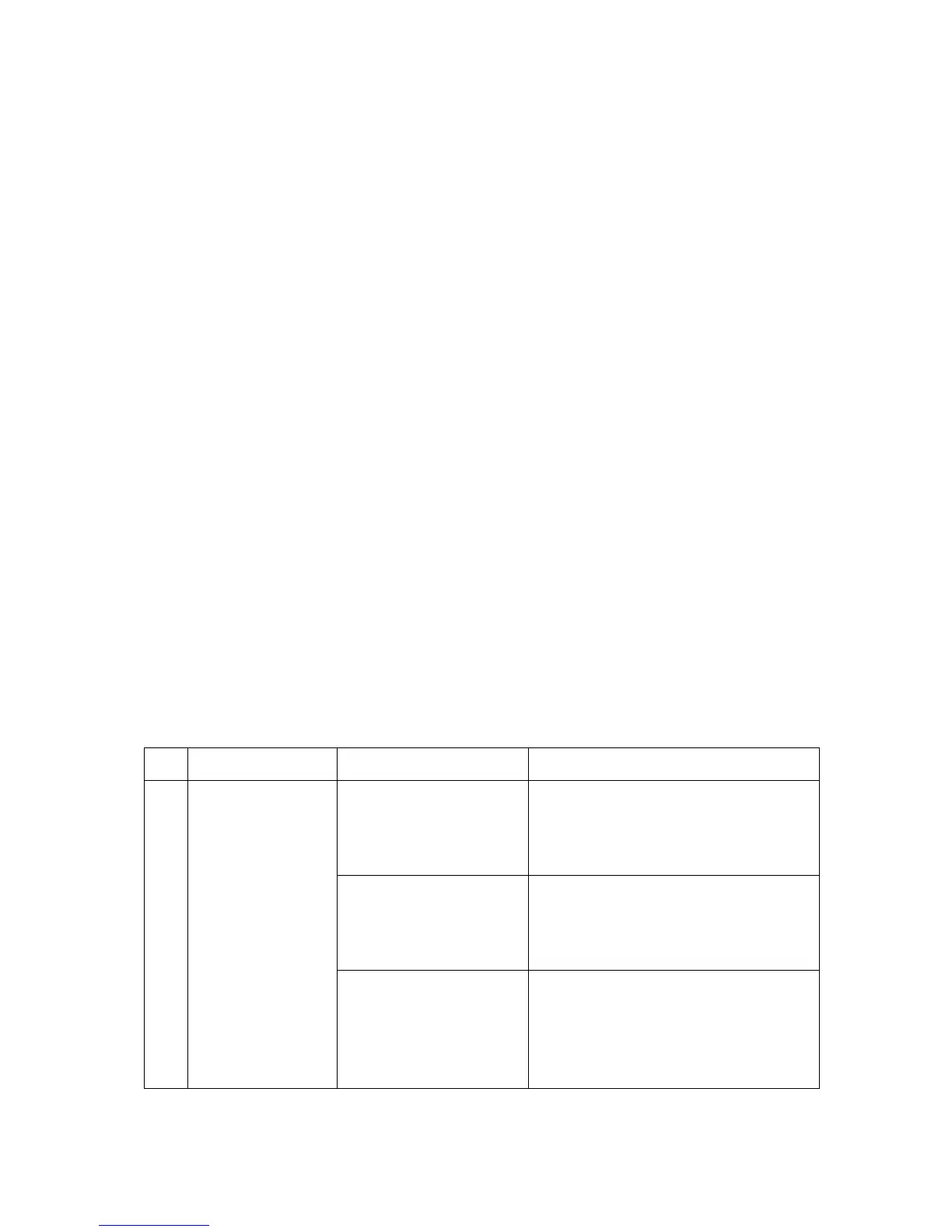

5.8. Operation faults and repairing procedures

No Operation fault Cause Method of repairing

Insufficient heat

capacity of the burner

Adjustment of operating

parameters is required – this

Loading...

Loading...