17

3.0 TRANSMISSION SYSTEM

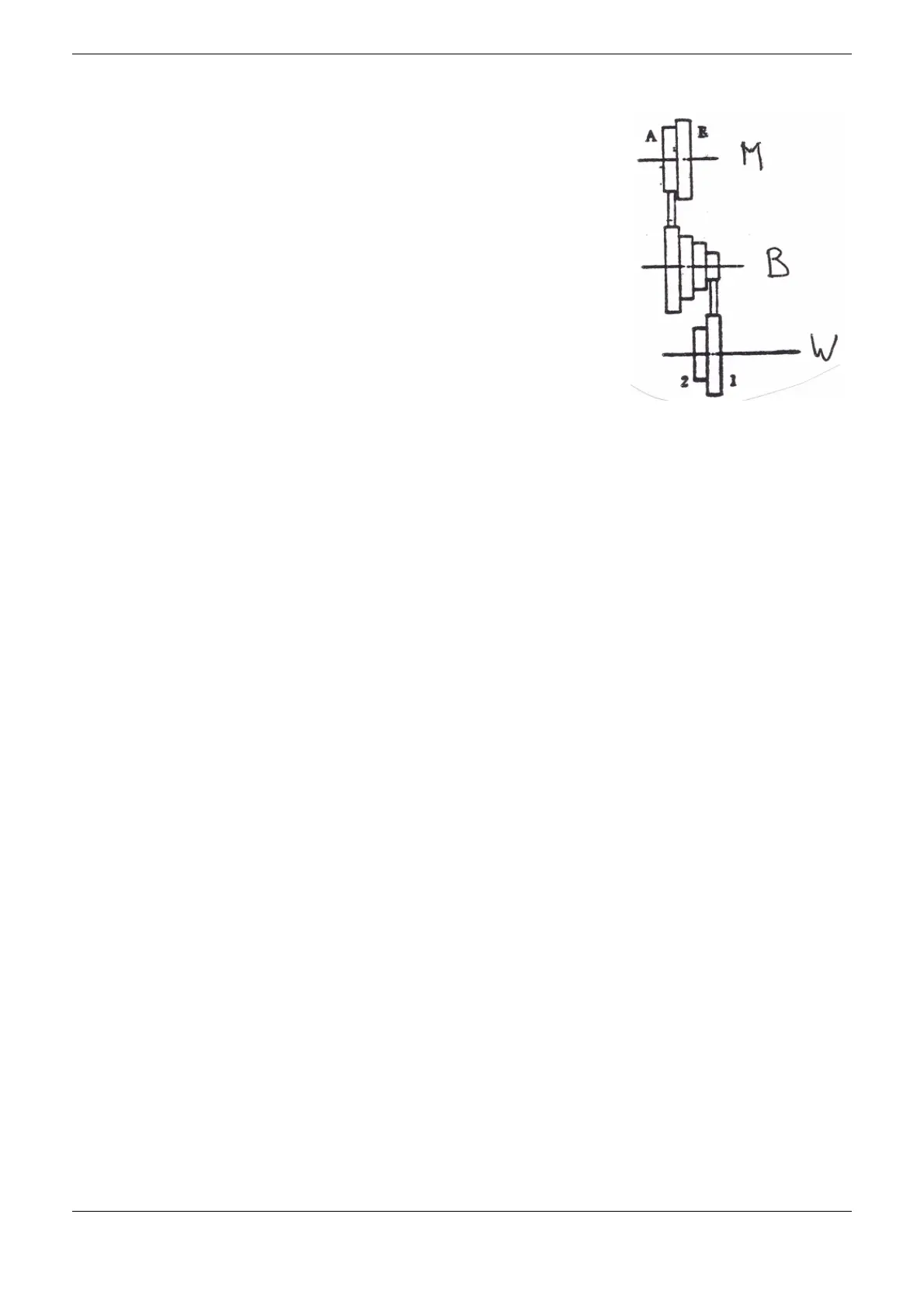

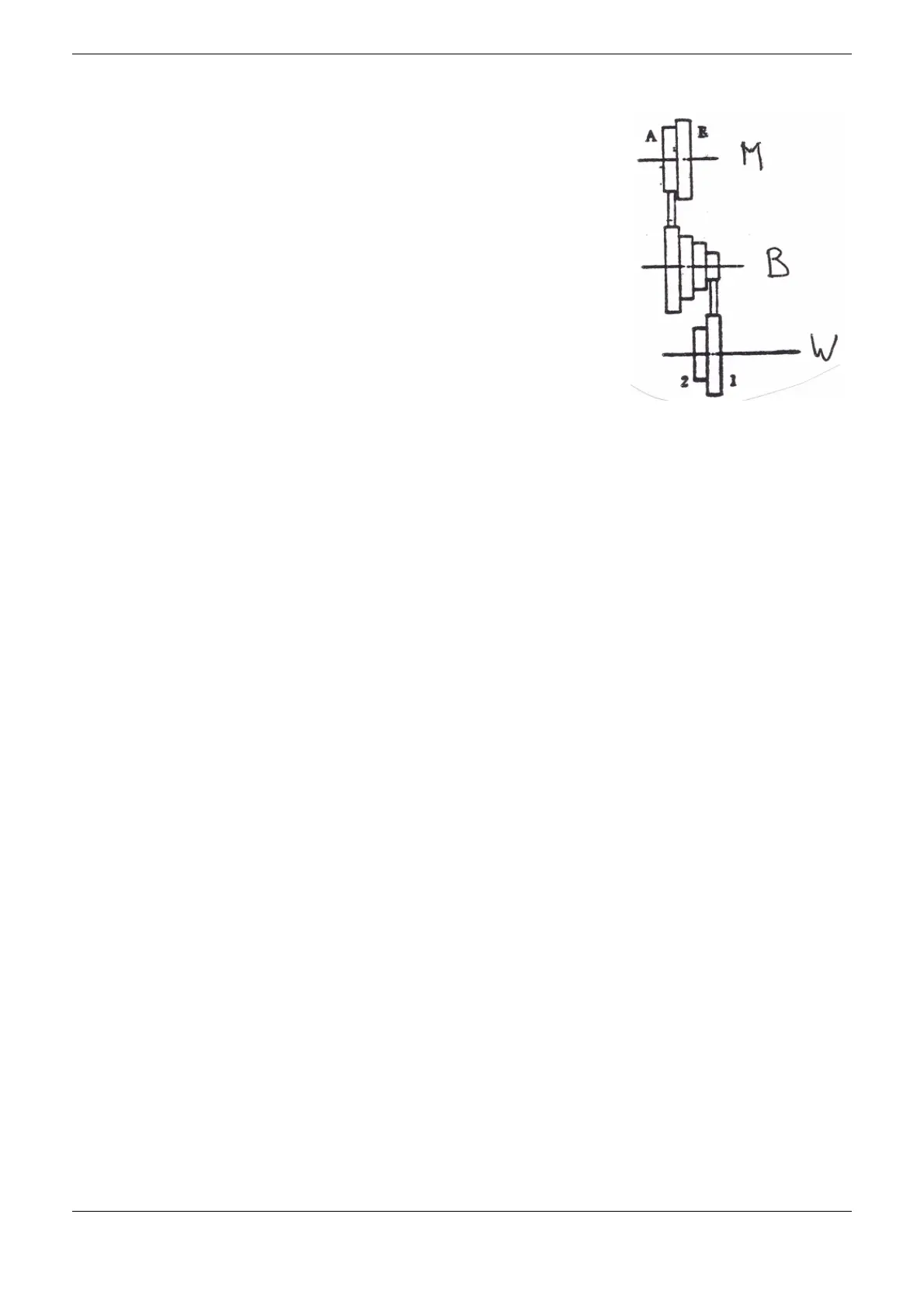

1. Main moving system

The four-grade speeds spining at the main

spindle of machine tool is realized by three

triangle belt cone pulleys, driven by triangle

belts, the speed changes is shown as Fig. 2.

Motor shaft

A: 1; 250 rpm.

A: 2; 500 rpm.

Bridge shaft

B: 1; 1000 rpm.

B: 2; 2000 rpm.

Fig. 2 Main spindle

2. Feed moving system

The longitudinal feed motion of the machine tool is done by a gear at the spindle

end, through a gear change transmitted to the leading screw and towing the slider,

the threads of which is as table 1 on page 29.

4.0 INSTALLATION AND TEST RUN

1. After opening package box, check whether the accessories of machine tool is

complete, whether machine tool and electric apparatus circuits have any

damage, according to packing list.

2. Install the machine tool securely on a solid platform with two M8 screw bolts.

3. When the lathe is transitted, all movable parts must be fixed, so as to avoid

machine tilt and damage by parts slid and impact.

4. Clear the anti-rust grease surfaces with gasoline and kerosene, pour some

mechanical oil on surfaces of slideway, tailstock sleeve, leading screw and

other places for lubrication.

5. Turn the handwheels by hand, check whether the moving parts are blocked or

loosened and make appropriate adjustments.

6. Insert the motor plug into a three-line socket (the grounding protection must be

secure and reliable).

7. Shift the machine speed in to minimum, start the motor. After running the main

spindle for 20 minutes, check whether different parts have abnormal condition,

increase the speed progressively to continue the test run.

8. Prior to test run and formal use of the machine, you must first read this

instruction manual carefully. Understand thoroughly the basic construction of

machine tool, the operating procedure, the lubricating condition, securities and

maintenance etc., then you can operate the lathe.

Loading...

Loading...