5

GB

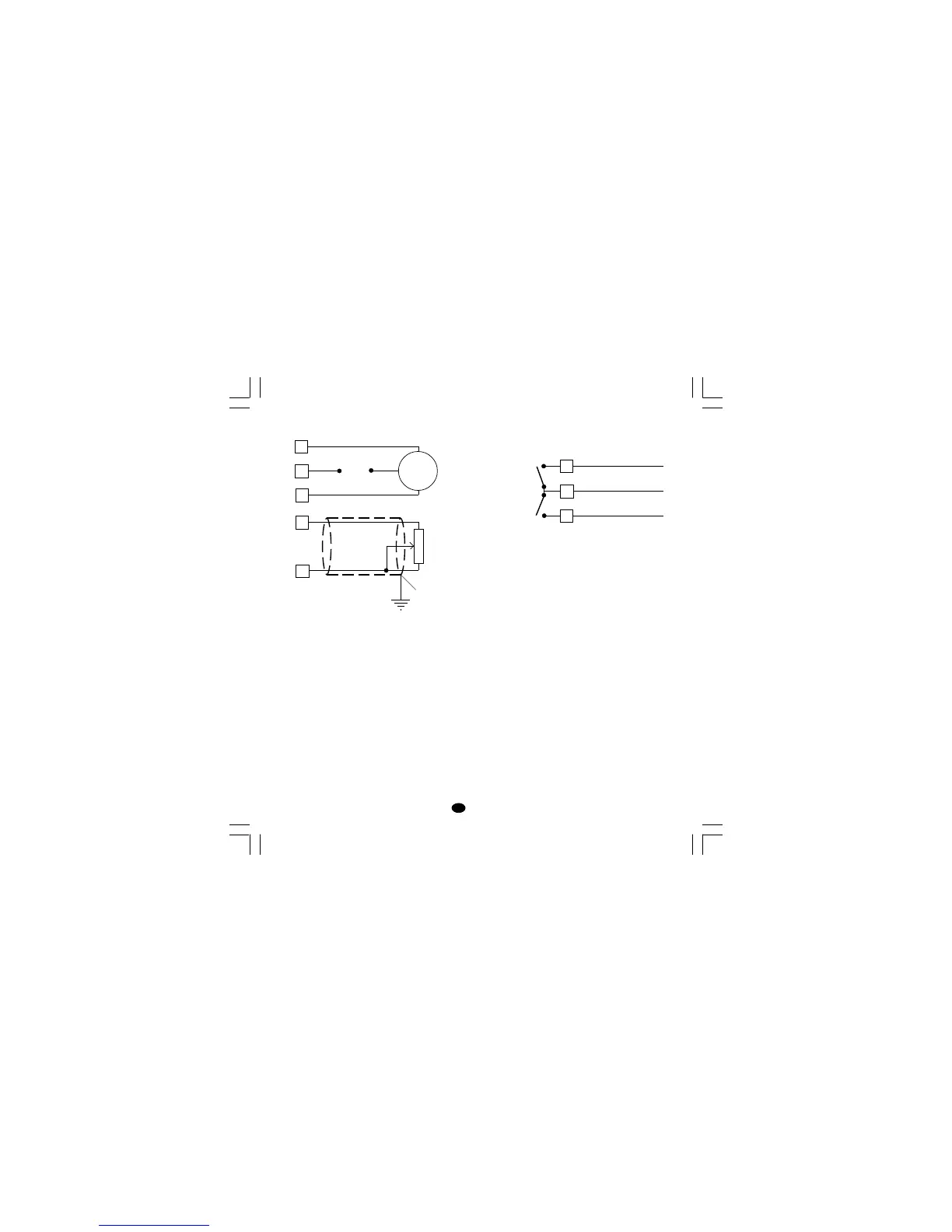

VALVE MOTOR DRIVE OUTPUT.

Fig. 8 - SERVOMOTOR WIRING

The two relay outputs are interlocked.

NOTE:

1) Before connecting the instrument to the power

line, make sure that line voltage and the load

current are in accordance with the contact rating

(3A/250V AC on resistive load).

2) To avoid electric shock, connect power line at the

end of the wiring procedure.

3) For servomotor connections use No 16 AWG or

larger wires rated for at last 75 °C.

4) Use copper conductors only.

5) Don’t run input wires together with power cables.

6) For feedback potentiometer, use shielded cable

with the shield connected to the earth at one point

only.

7) The relay outputs are protected by varistor

against inductive load with inductive compo-

nent up to 0.5 A.

1

2

3

Servo-

motor

Power

line

s (Open the valve)

t (Close the valve)

RELAY OUTPUTS

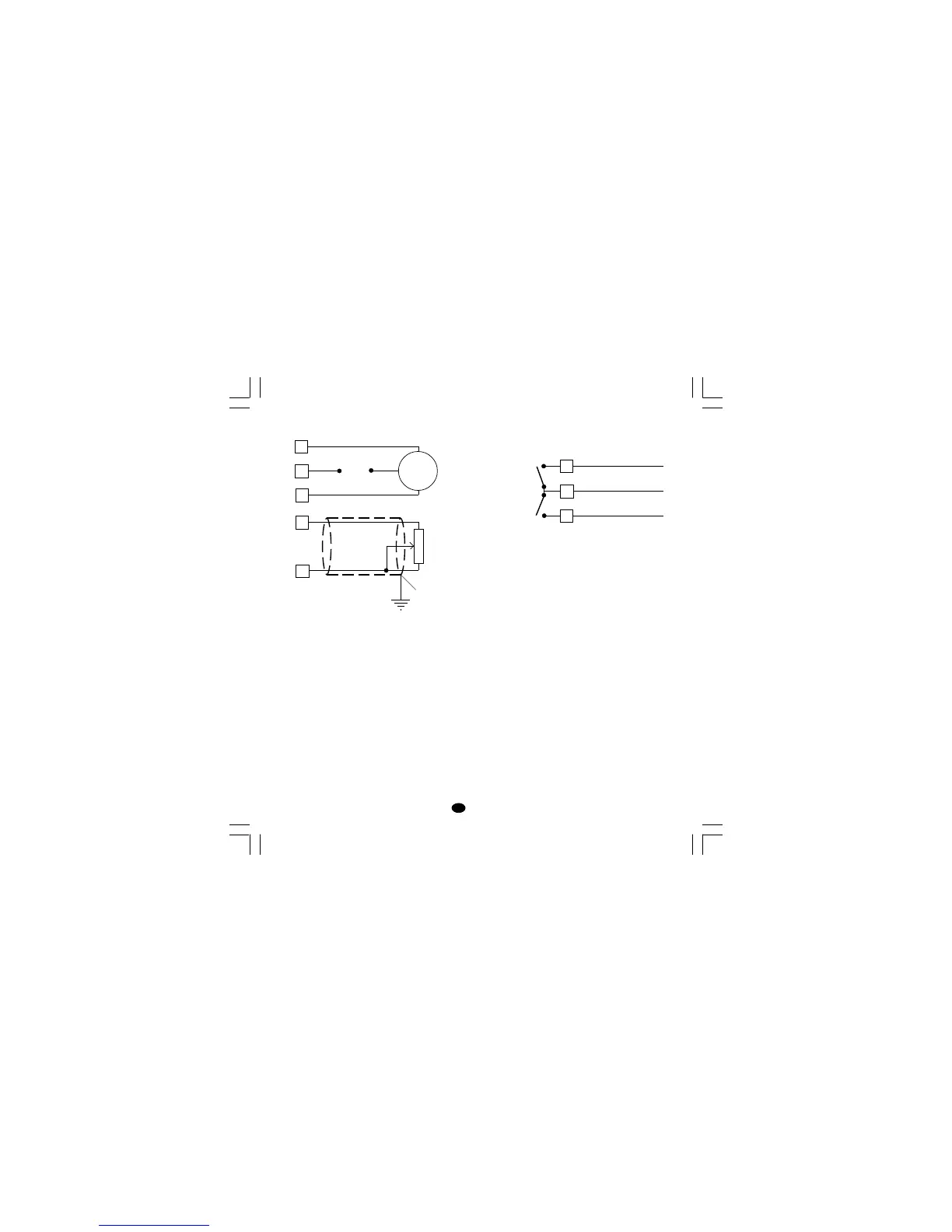

Fig. 9 RELAY OUTPUTS WIRING

NOTE: OUT 1 can be used either as servomotor

output or as time proportional relay output;

by the P5 parameter (see pag.11) it is

possible to set the desired output.

All relay outputs are protected by varistor against

inductive load with inductive component up to 0.5 A.

The contact rating of the OUT 3 and 4 is 2A/250V AC

resistive load.

The number of operations is 1 x 10

5

at specified

rating.

Alarm 2 and alarm 3 are in OR condition on the

out 4.

The following recommendations avoid serious

problems which may occur, when using relay

output for driving inductive loads.

8

6

7

C - OUT 3/4

NO - OUT 4

NO - OUT 3

OUT 4

OUT 3

14

15

Feedback

potentiometer

Shield

LFS-servo-1-02.p65 1/14/02, 3:43 PM5

Loading...

Loading...