-- 2 0 --

dha4d1ea

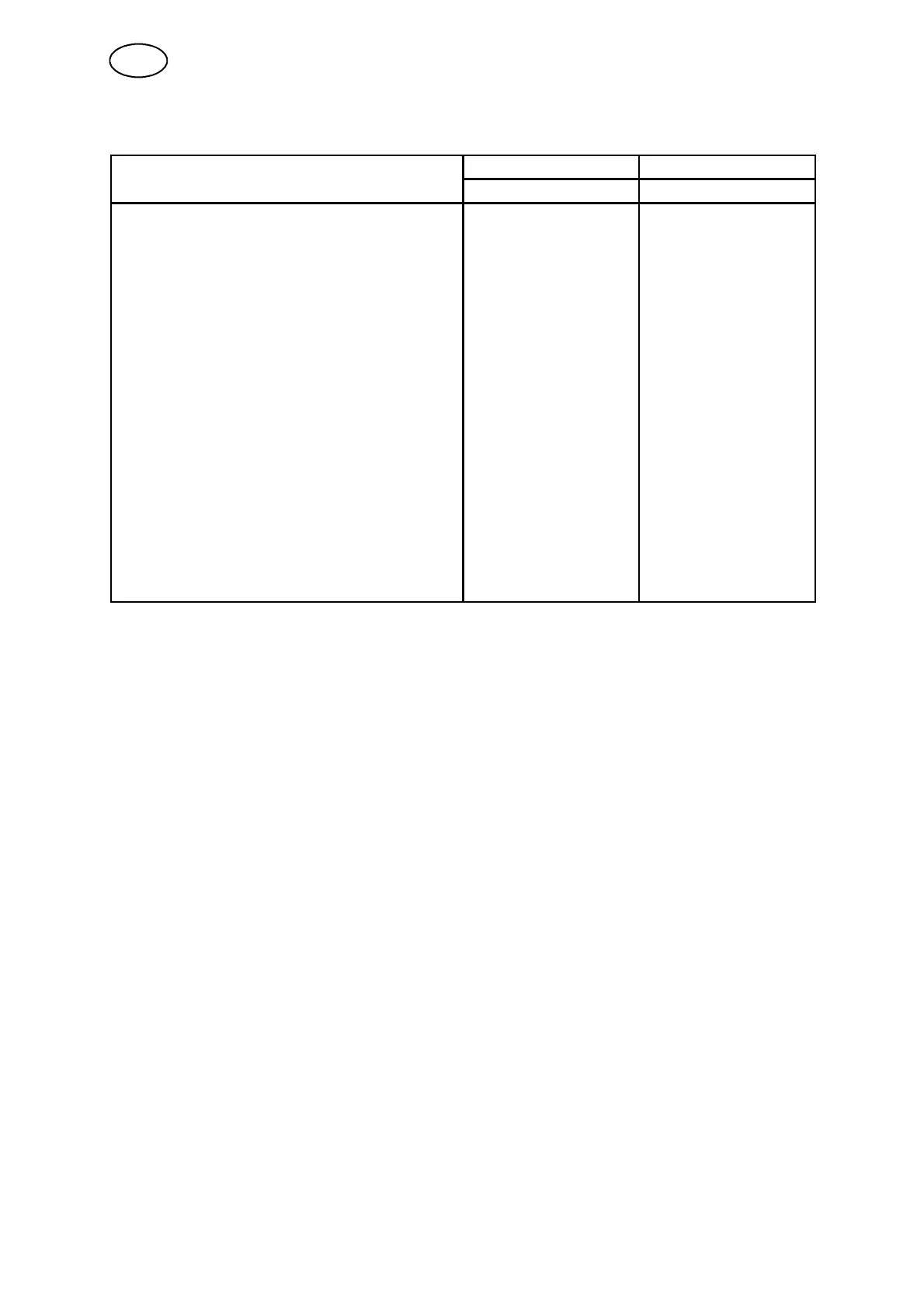

2.2 Technical data

A2 TFE1 A2 TGE1

2

u

t

trac

UP MIG/MAG

Supply voltage 42 V AC 42 V AC

Rating 100 % 800 A DC 600 A DC

Wire sizes:

solid single wire 1.6--4.0 mm 0.8--1.6 mm

hollow wire 1.6--4.0 mm 1.2--2.4 mm

twin wire 2x1.2--2.5 mm -- --

Wire feed speed, max 9m/min 19 m/min

Brake hub braking torque 1.5 Nm 1.5 Nm

T ravel speed 0.1--2.0 m/min 0.1--2.0 m/min

T urning radius for circumferential welding, min 1500 mm 1500 mm

Pipe diameter for internal joint welding, min 1100 mm 1100 mm

Electrode weight, max 30 kg 30 kg

Flux container volume (Must not be filled with

preheated powder)

6l -- --

Weight (excl. wire and flux) 47 kg 43 kg

T ransverse inclination, max

25_ 25_

Continuous A--weighted noise pressure 68 dB 83 dB

2.3 Welding method

Submerged--arc welding

For submerged--arc welding, an A2 Multitrac of type A2 TFE1 UP light duty is used,

with a Ø 20 mm connector which permits a load of up to 800 A (100%) or 1000 A

(60%).

The welding head can be equipped with feed rollers for single or twin wire welding

(twin--arc). A special knurled feed roller is available for flux--cored wire, which

guarantees even wire feed without the risk of deformation due to high feed pressure.

MIG/MAG welding

For MIG/MAG welding, an A2 Multitrac A2 T GE1 is used, which has a maximum

rated load of 600 A. The welding head is water cooled, with the cooling water

supplied by hoses from connections intended for the purpose.

Connection instructions for submerged--arc and MIG/MAG welding are shown in the

connection diagram, see pages 22 and 23.

GB

Loading...

Loading...