-- 2 4 --

dha4d1ea

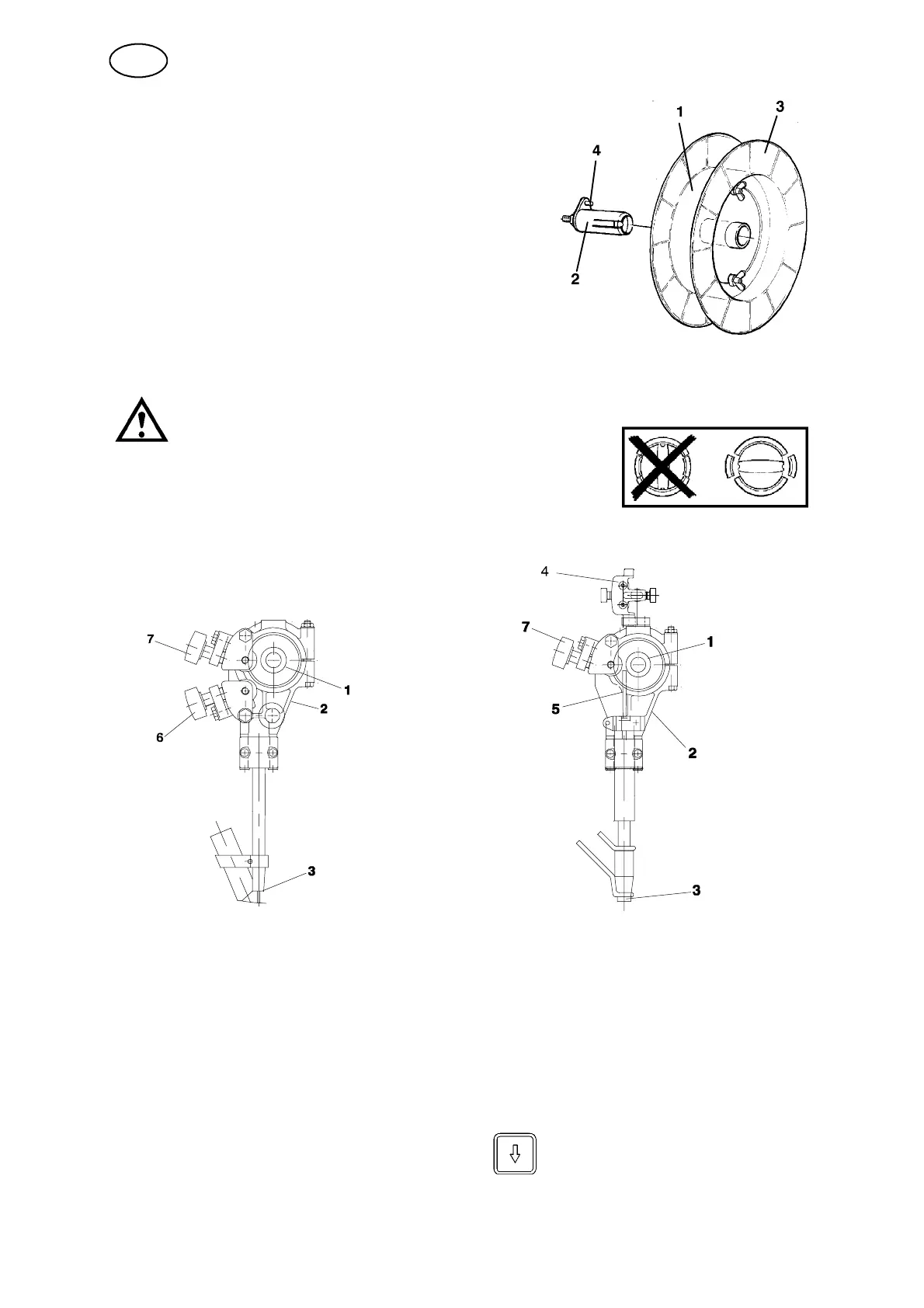

2. Loading the welding wire

S Remove the wire drum (1) from the brake hub (2)

and take off the side plate (3).

S Locate the wire reel on the wire drum (1).

S Cut off the binding wires from around the

wire reel.

S Replace the side plate (3).

S Replace the wire drum (1) on the brake hub (2).

Check that the carrier (4) is in the correct position.

NOTE! The maximum angle for the wire bobbin is 25°.

At extreme angles, wear will occur on the brake hub locking

mechanism and the wire bobbin will slide off the brake hub.

IMPORTANT!

To prevent the reel sliding off the hub: Lock the reel in place

by turning the red knob as shown on the warning label atta-

ched next to the hub.

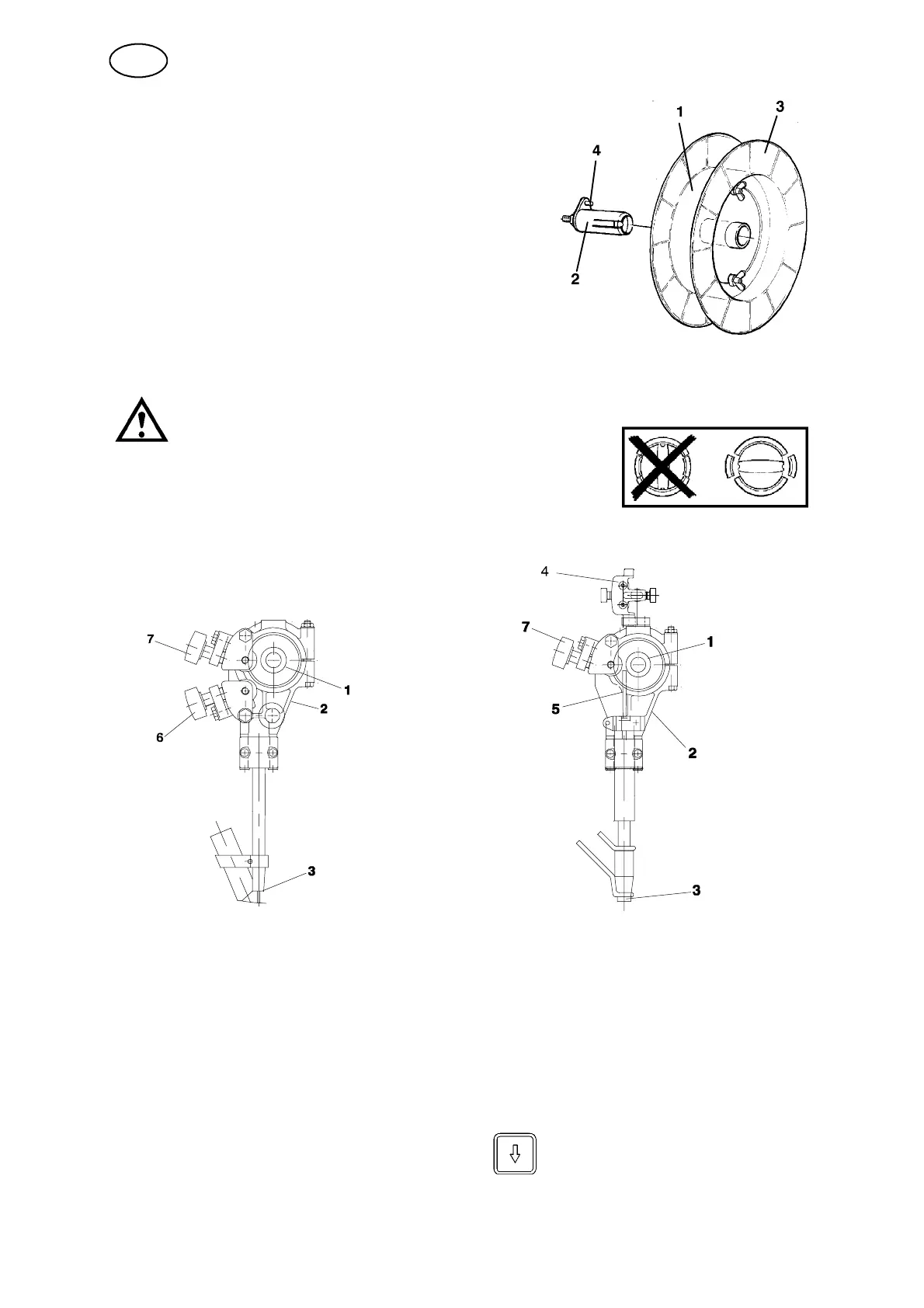

SAW MIG/MAG

S Check that the feed roller (1) and contact jaw or contact tip (3) are of the correct

dimension for the selected wire size.

S Pull the end of the wire through the straightener (2). For a wire diameter greater

than 2 mm; straighten out 0.5 m of wire and feed it by hand down through the

straightener.

S Locate the end of the wire in the feed roller (1) groove.

S Set the wire tension on the feed roller with the knob (7). Note! Do not tension

more than is required to achieve an even feed.

S Feed the wire forward 30 mm by pressing on the control box A2--A6

Process Controller.

GB

Loading...

Loading...