-- 7 2 --

ffa9d1ea

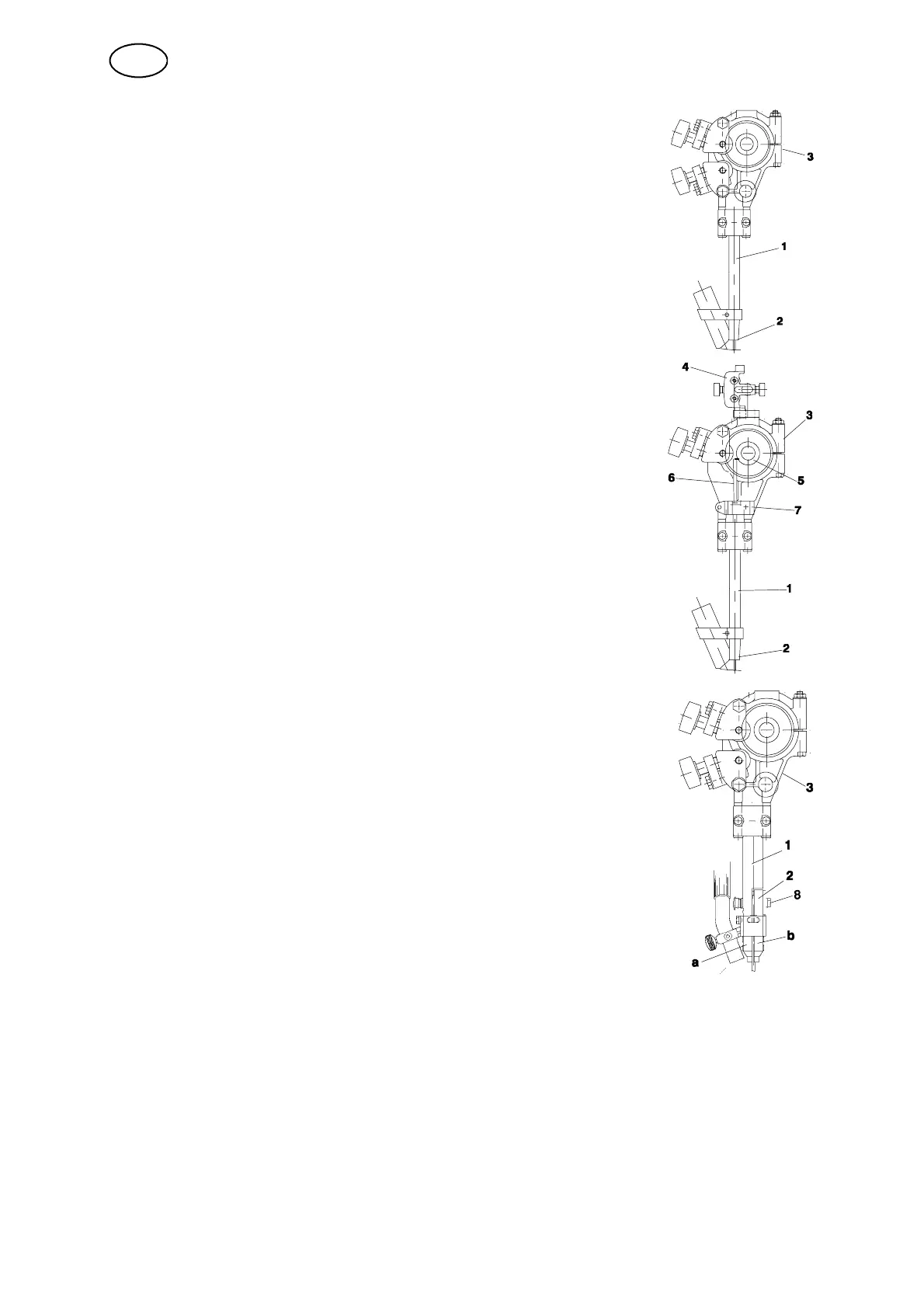

Contact equipment for submerged--arc welding

S For single wire 3.0 -- 4.0 mm. Light duty (D20)

Use the straightener (3), connector (1) D20 with contact tip (2)

(M12 thread).

S Tighten the contact tip (2) with a key in order to ensure

that a good contact is achieved.

S For single wire 1.6 -- 2.5 mm Submerged--arc.

Light duty (D20)

Use the straightener (3), connector (1) D20 with contact

tip ( 2) (M12 thread) and separate fine wire straightener (4)

with guide tube (6).

S Fit the clamp (7) with guide tube (6) in the M12 hole on

the straightener (3). The guide tube (6) should bottom

on the contact tip (2).

S If necessary, cut the guide tube (6) to length so that the

feed roller (5) runs freely.

S Fit the fine wire straightener (4) on the upper side of the

clamp for the straightener (3).

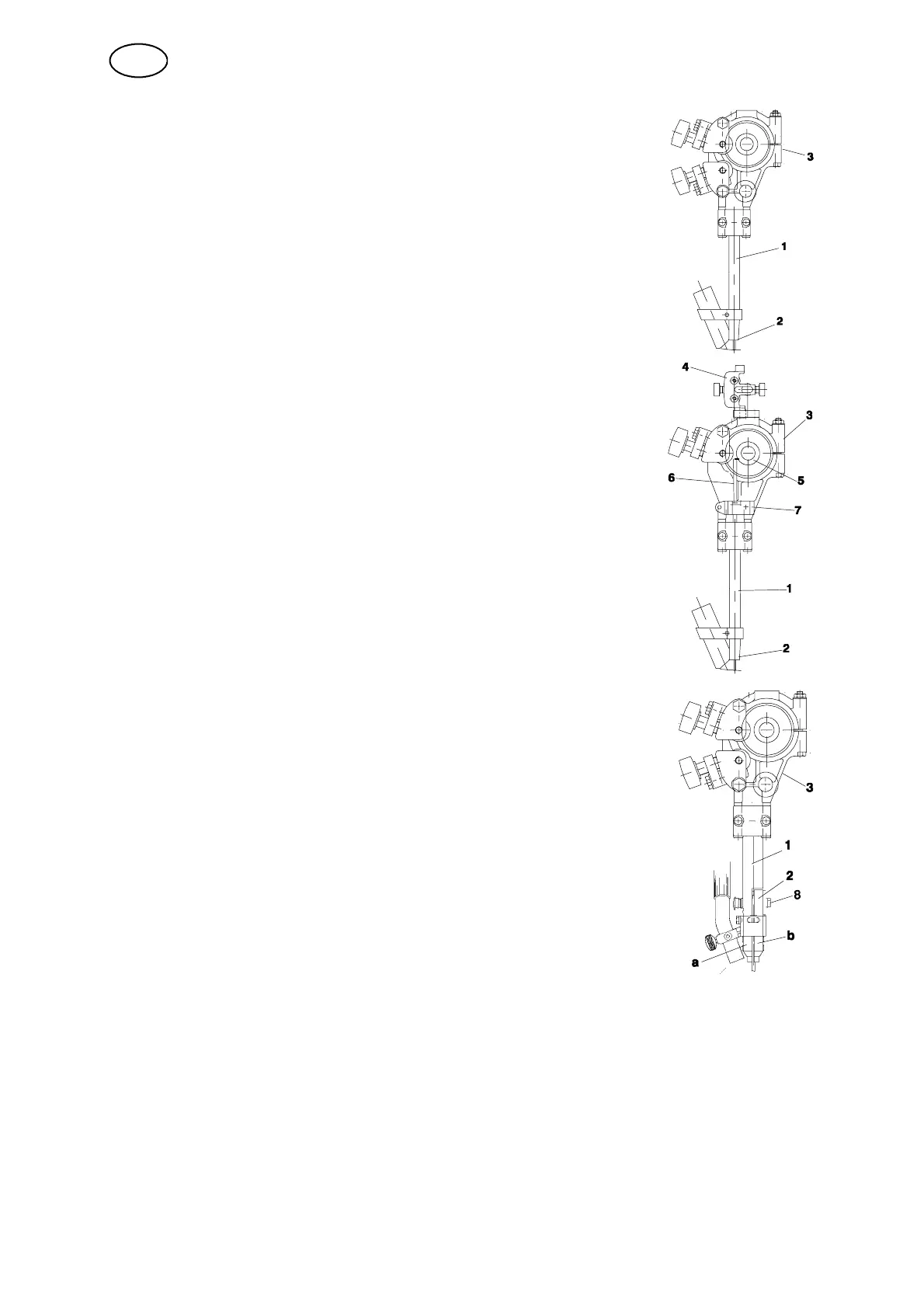

S For single wire 3.0 -- 6.0 mm. Heavy duty (D35)

Use the straightener (3), connector (1) D35 with contact

jaws (2).

S Fit one of the contact jaws with the M5 bolts provided, in

the fixed contact tip (a).

S Fit the other contact jaw in the free half of the two --piece

connector (b) under the bolt (8) and tighten down hard to

ensure that a good contact is achieved between the

contact jaws and the wire.

S For flu x--cored wire 1.6 mm -- 4.0 mm ( D20 and D35) (Accessories)

If contact jaws (D35) are used, the contact jaws must not be tightened too hard

in order that the flux--cored wire is not deformed. Ensure that good contact is

achieved with the wire.

S Adjustment of the wire for tandem welding

S The distance between the first and second wire must not be so great that the

slag gets time to solidify between the wires.

S Ensure that good flux coverage is achieved between the first and second

wires.

GB

Loading...

Loading...