-- 6 7 --

ffa9d1ea

MIG/MAG welding

For MIG/MAG welding the A6 SG welding head is always used, permitting a max.

load of 600 A. The welding head is water--cooled, with the cooling water supplied by

hoses from connections intended for the purpose.

3.5 Equipment

Included in a complete welding head are a feed motor (A6 VEC) to feed in the wire

and contact equipment which supplies current to the wire and provides a good con-

tact.

Contact equipment is available in several different versions.

S A6 SF is used for submerged--arc welding.

S A6 SG is used for M IG/MAG welding.

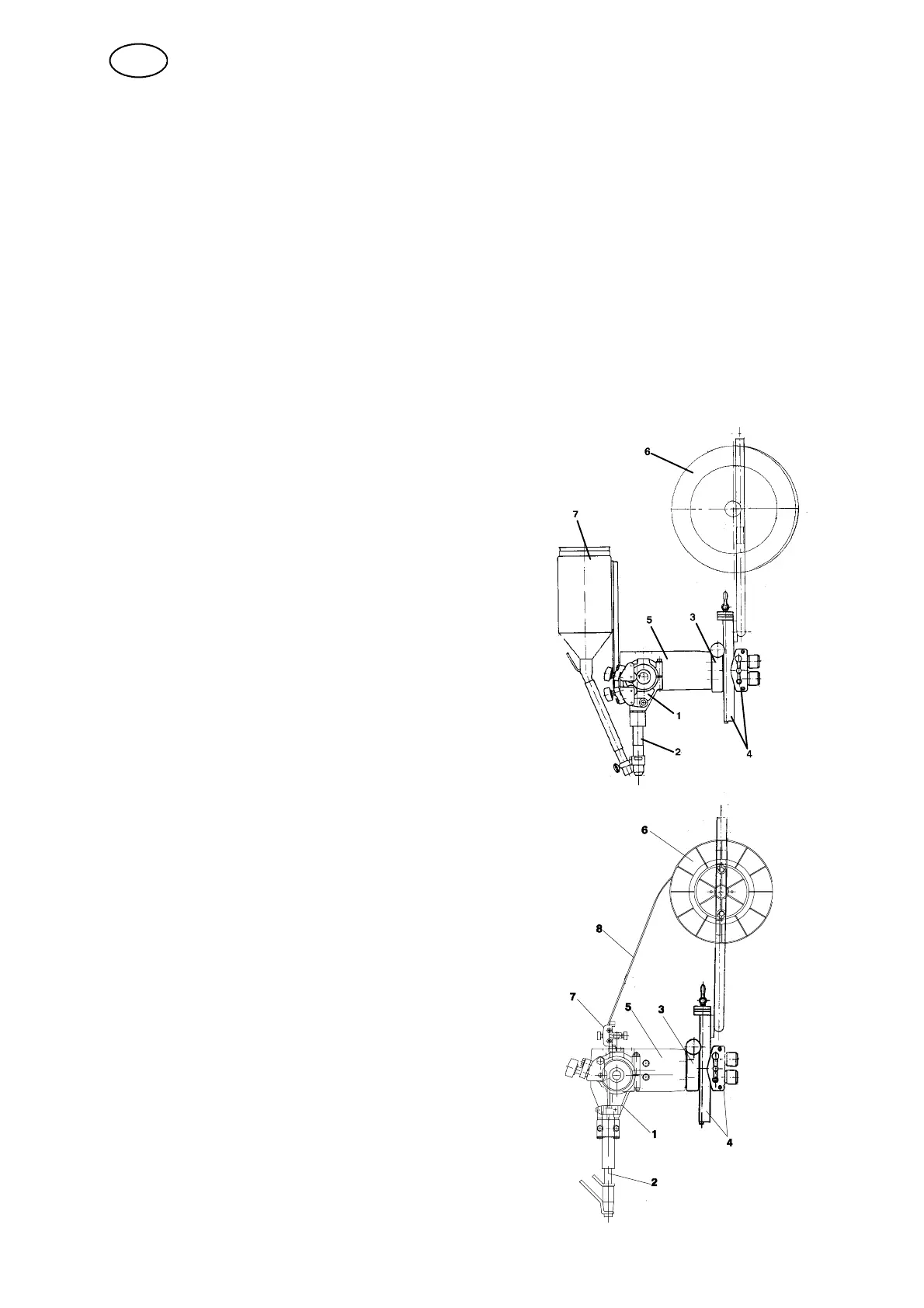

Example -- A6 SFE1 and A6 SFE2

1 Straightener.

2 Contact equipment which consists of a

contact tip, connector and flux tube.

3 Angular slide

4 Slide (motor--driven or manually operated)

5 Motor and gearbox (A6 VEC)

6 Wire drum

7 Flux hopper (may be fitted with a cyclone)

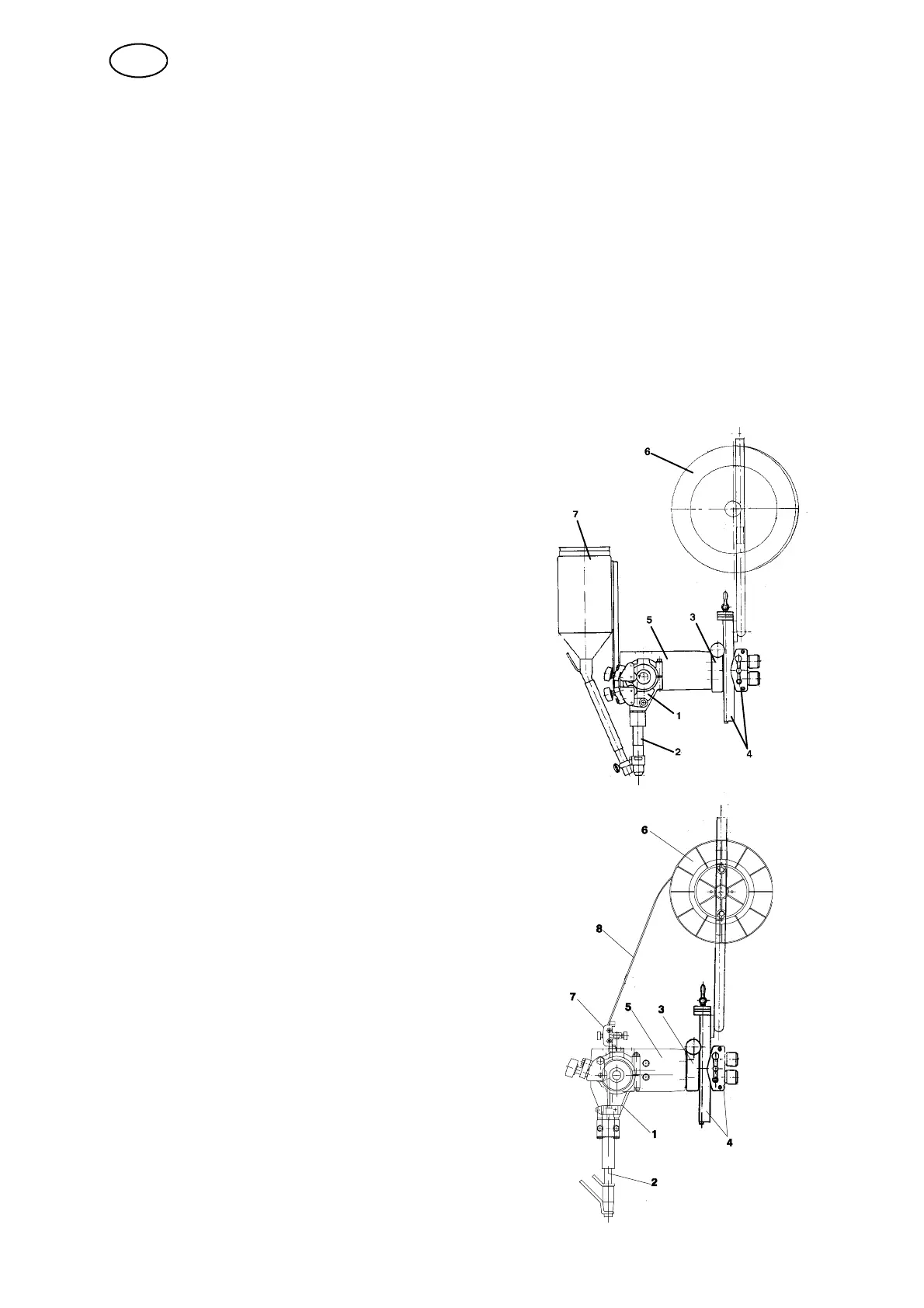

Example -- A6 SGE1

1 Straightener.

2 Contact equipment which consists of a

connector, gas nozzle and water hoses.

3 Angular slide.

4 Slide (motor--driven or manually operated)

5 Motor and gearbox (A6 VEC).

6 Wire drum.

7 Fine--wire straightener (Accessories).

8 Wire guide.

GB

Loading...

Loading...