- 15 -

hfb6d1ea

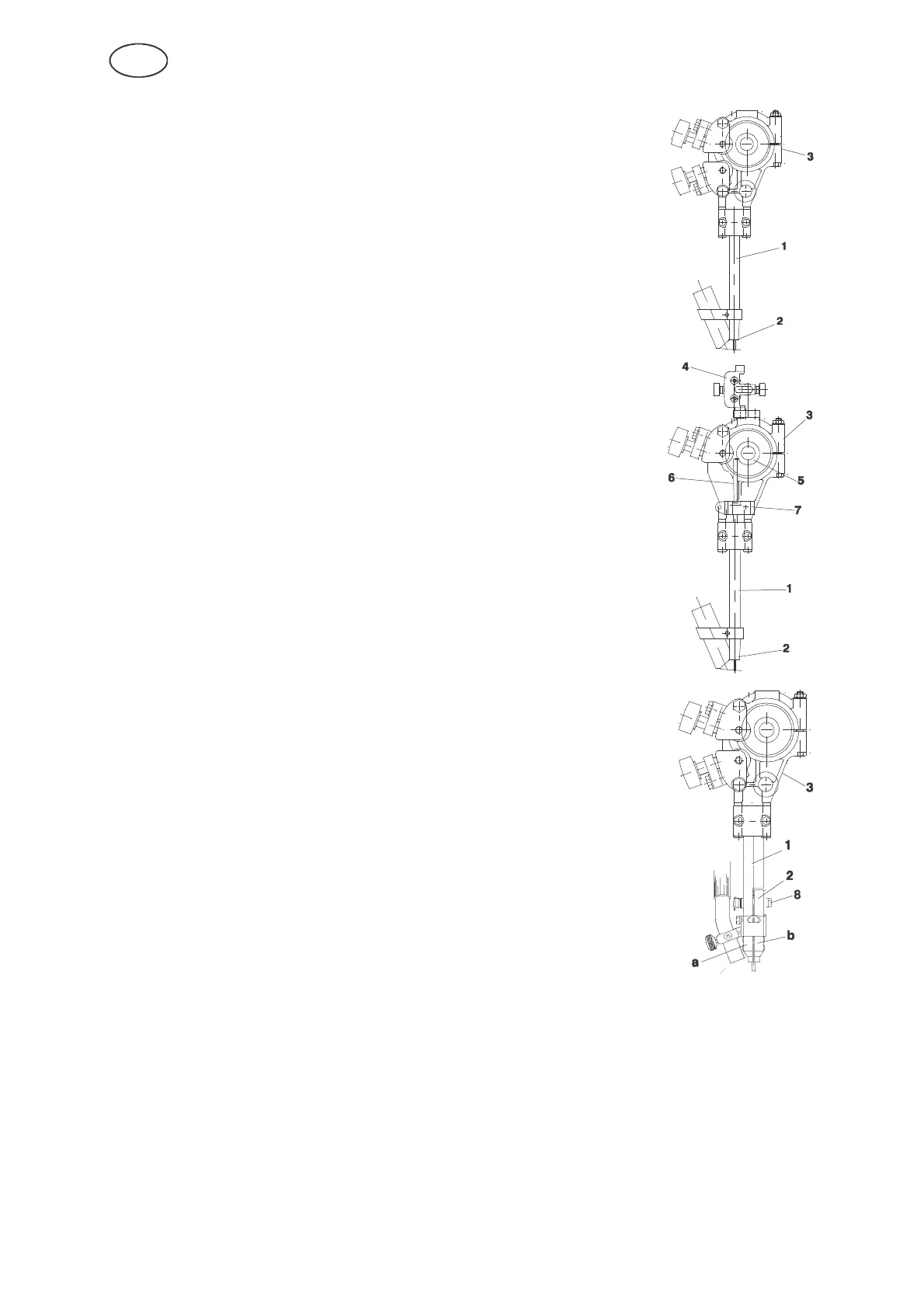

Contact equipment for submerged-arc welding

For single wire 3.0 - 4.0 mm. Light duty (D20)

Use the straightener (3), connector (1) D20 with contact tip (2)

(M12 thread).

Tighten the contact tip (2) with a key in order to ensure

that a good contact is achieved.

For single wire 1.6 - 2.5 mm Submerged-arc.

Light duty (D20)

Use the straightener (3), connector (1) D20 with contact

tip (2) (M12 thread) and separate fine wire straightener (4)

with guide tube (6).

Fit the clamp (7) with guide tube (6) in the M12 hole on

the straightener (3). The guide tube (6) should bottom

on the contact tip (2).

If necessary, cut the guide tube (6) to length so that the

feed roller (5) runs freely.

Fit the fine wire straightener (4) on the upper side of the

clamp for the straightener (3).

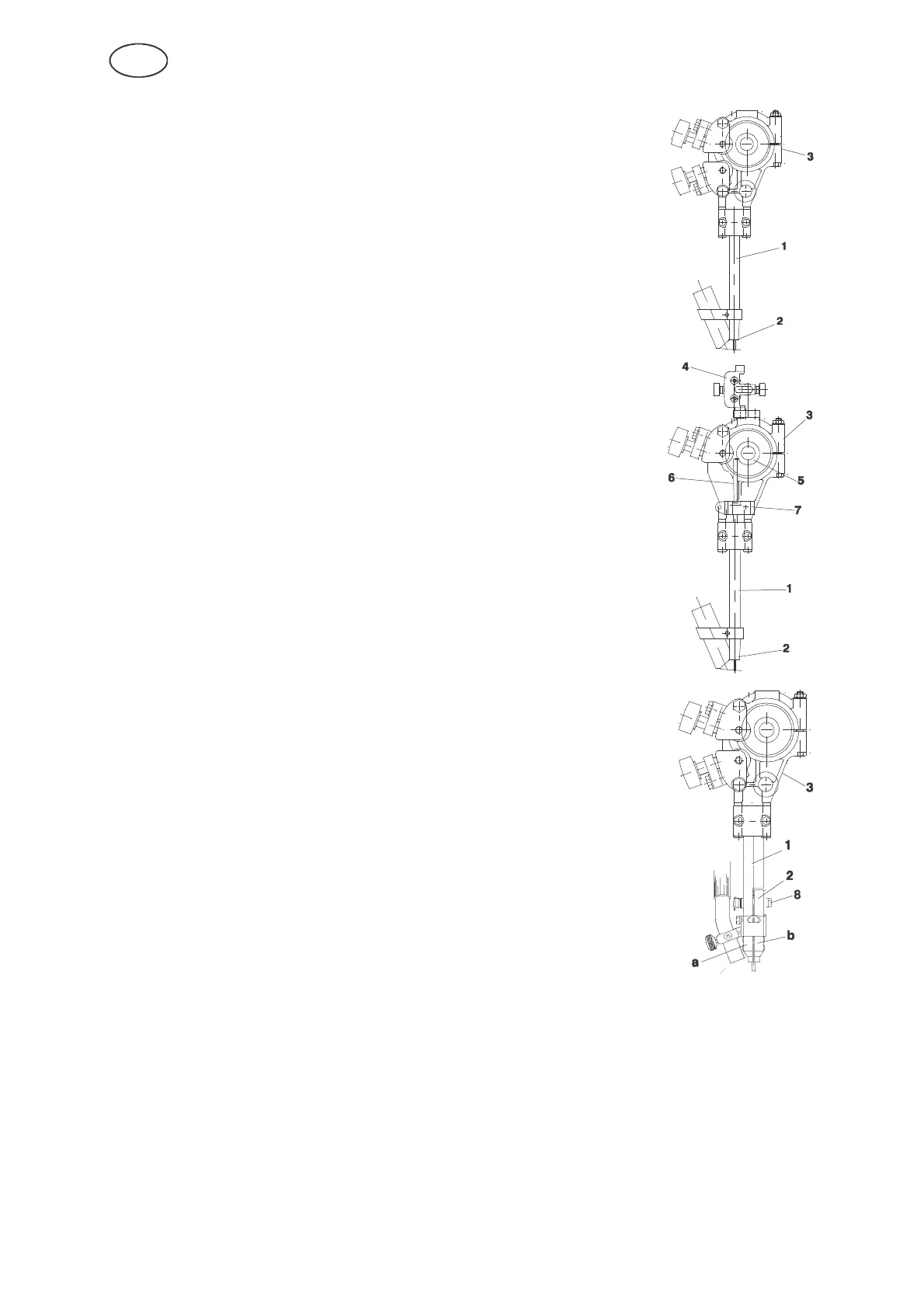

For single wire 3.0 - 6.0 mm. Heavy duty (D35)

Use the straightener (3), connector (1) D35 with contact

jaws (2).

Fit one of the contact jaws with the M5 bolts provided, in

the fixed contact tip (a).

Fit the other contact jaw in the free half of the two-piece

connector (b) under the bolt (8) and tighten down hard to

ensure that a good contact is achieved between the

contact jaws and the wire.

For flux-cored wire 1.6 mm - 4.0 mm (D20 and D35) (Accessories)

If contact jaws (D35) are used, the contact jaws must not be tightened too hard

in order that the flux-cored wire is not deformed. Ensure that good contact is

achieved with the wire.

Adjustment of the wire for tandem welding

The distance between the first and second wire must not be so great that the

slag gets time to solidify between the wires.

Ensure that good flux coverage is achieved between the first and second

wires.

GB

Loading...

Loading...