© ESAB AB 2008

- 13 -

bm50d1ea

6 MAINTENANCE

Regular maintenance is important for safe, reliable operation.

CAUTION

All guarantee undertakings from the supplier cease to apply if the customer attempts any

work to rectify any faults in the product during the guarantee period.

6.1 Inspection and cleaning

Wire feed unit

Check regularly that the wire feed unit is not clogged with dirt.

Cleaning and replacement of the wire feed unit mechanism's worn parts should

take place at regular intervals in order to achieve trouble-free wire feed. Note

that if pre-tensioning is set too hard, this can result in abnormal wear on the

pressure roller, feed roller and wire guide.

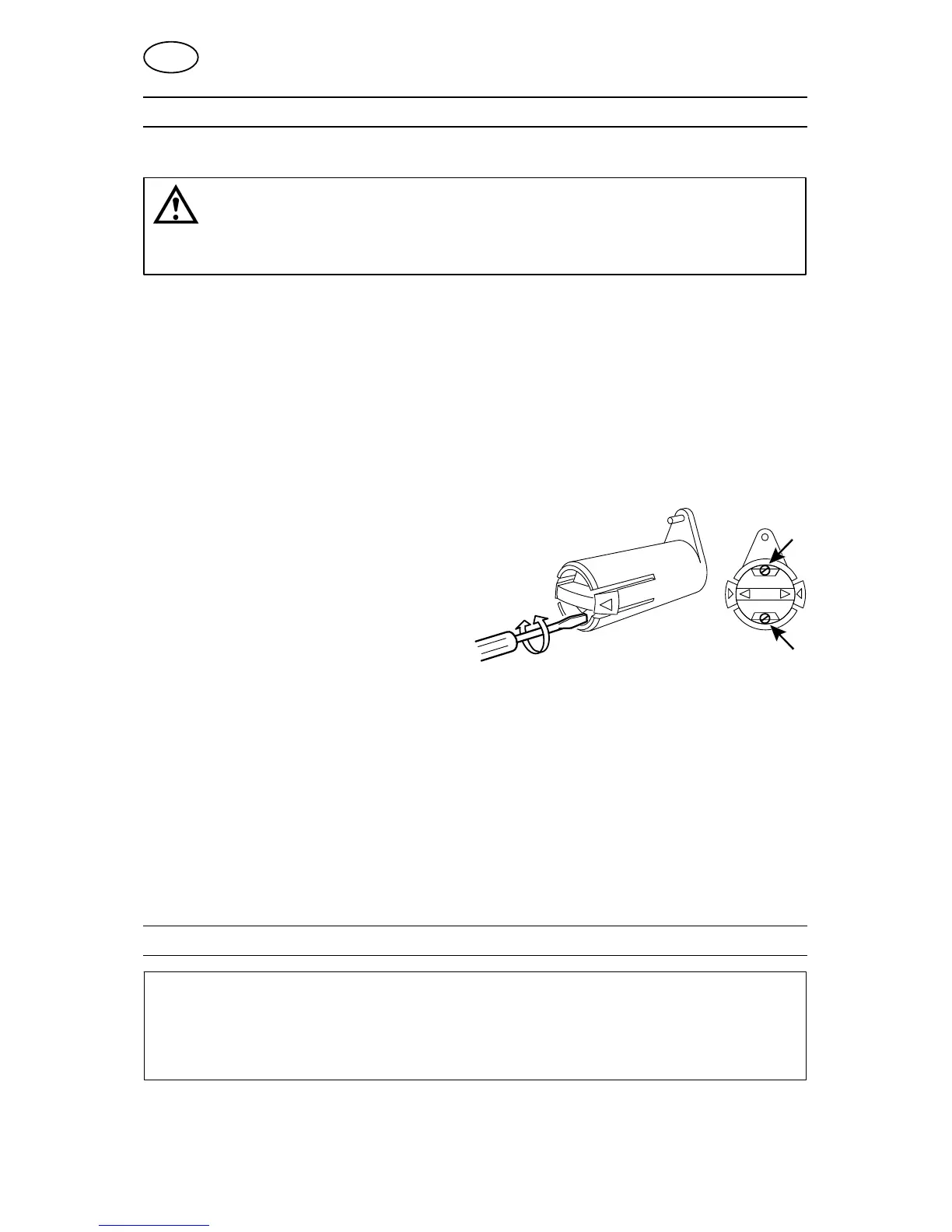

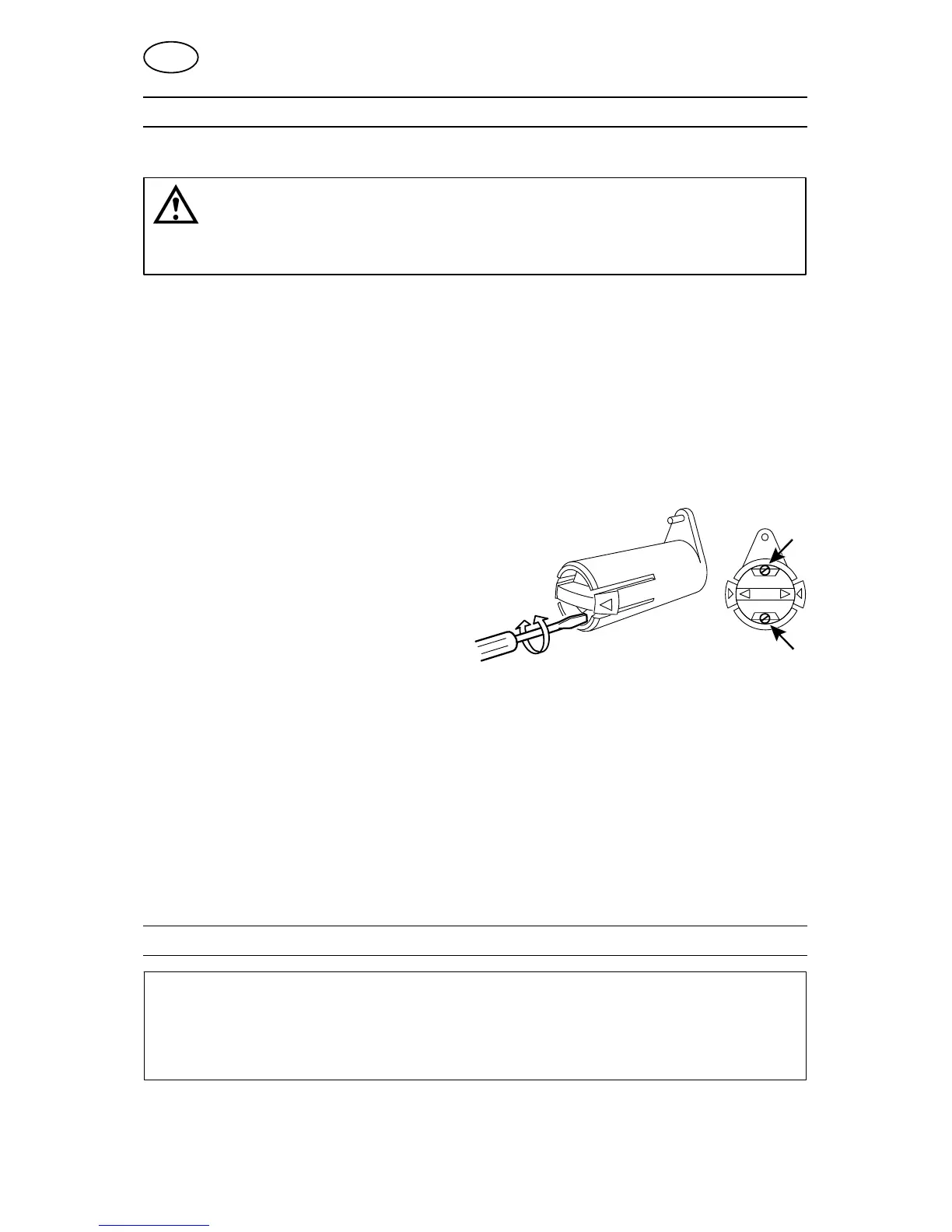

The brake hub

The hub is adjusted when delivered, if

readjustment is required, follow the instructions

below. Adjust the brake hub so that wire is slightly

slack when wire feed stops.

Adjusting the braking torque:

Turn the red handle to the locked position.

Insert a screwdriver into the springs in the hub.

Turn the springs clockwise to reduce the braking torque

Turn the springs counter-clockwise to increase the braking torque. NB: Turn

both springs the same amount.

Welding gun

The welding gun's wear parts should be cleaned and replaced at regular

intervals in order to achieve trouble-free wire feed. Blow the wire guide clean

regularly and clean the contact tip.

7 ORDERING SPARE PARTS

FEED 3004, Feed 4804 is designed and tested in accordance with the international and

European standards IEC/EN 60974-5 and IEC/EN 60974-10. It is the obligation of the

service unit which has carried out the service or repair work to make sure that the pro

duct still conforms to the said standard.

Spare parts may be ordered through your nearest ESAB dealer, see the last page of

this publication.

GB

Loading...

Loading...