-- 9 --

MM215Pe

6 OPERATION

General safety regulations for the handling of the equipment can be found on

page 4. Read through before you start using the equipment!

WARNING!

Rotating parts can cause injury, take great care.

WARNING -- TIPPING RISK!

There is a risk of tipping while transportation and operation, if the welding machine leans

more than 10

o

. In that case appropriate securing has to be provided !

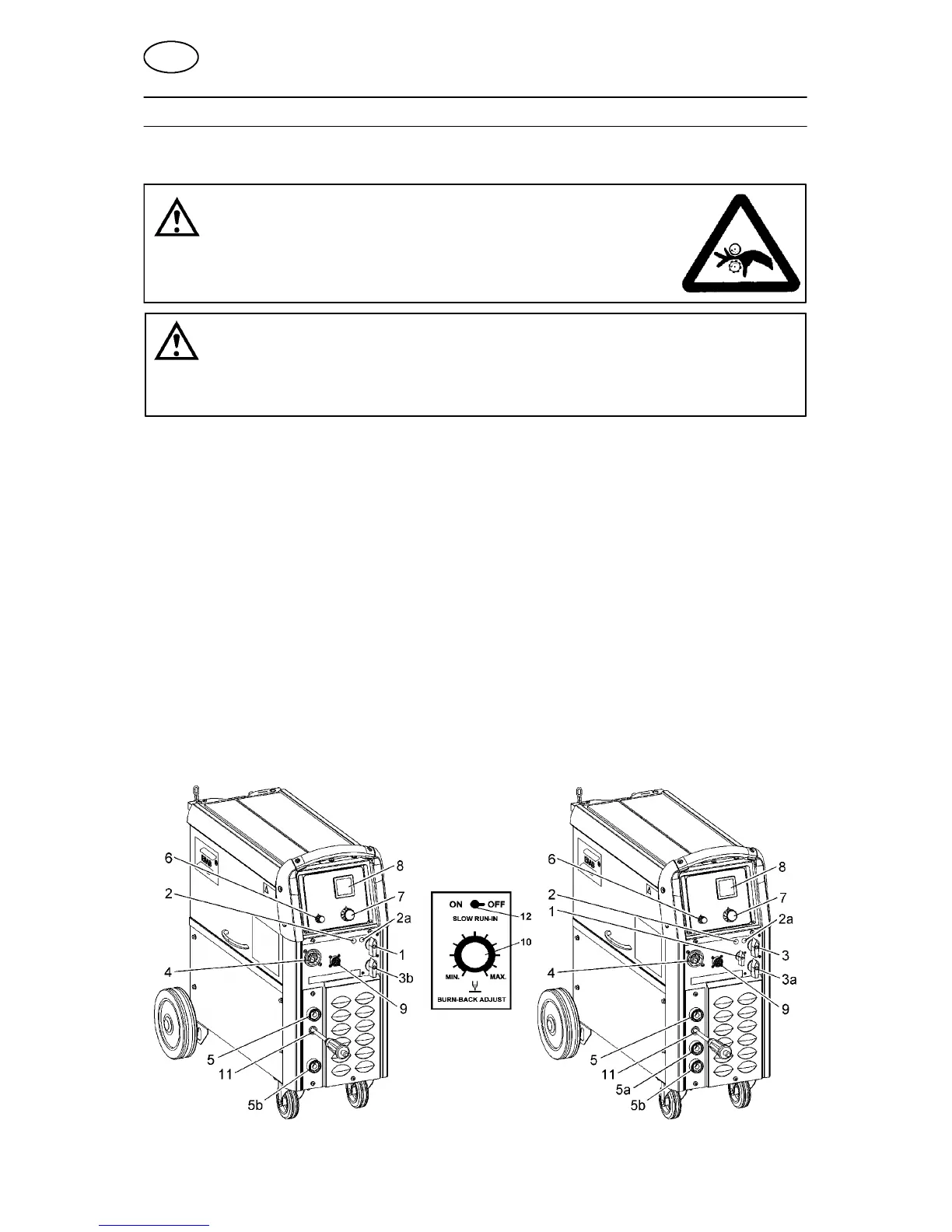

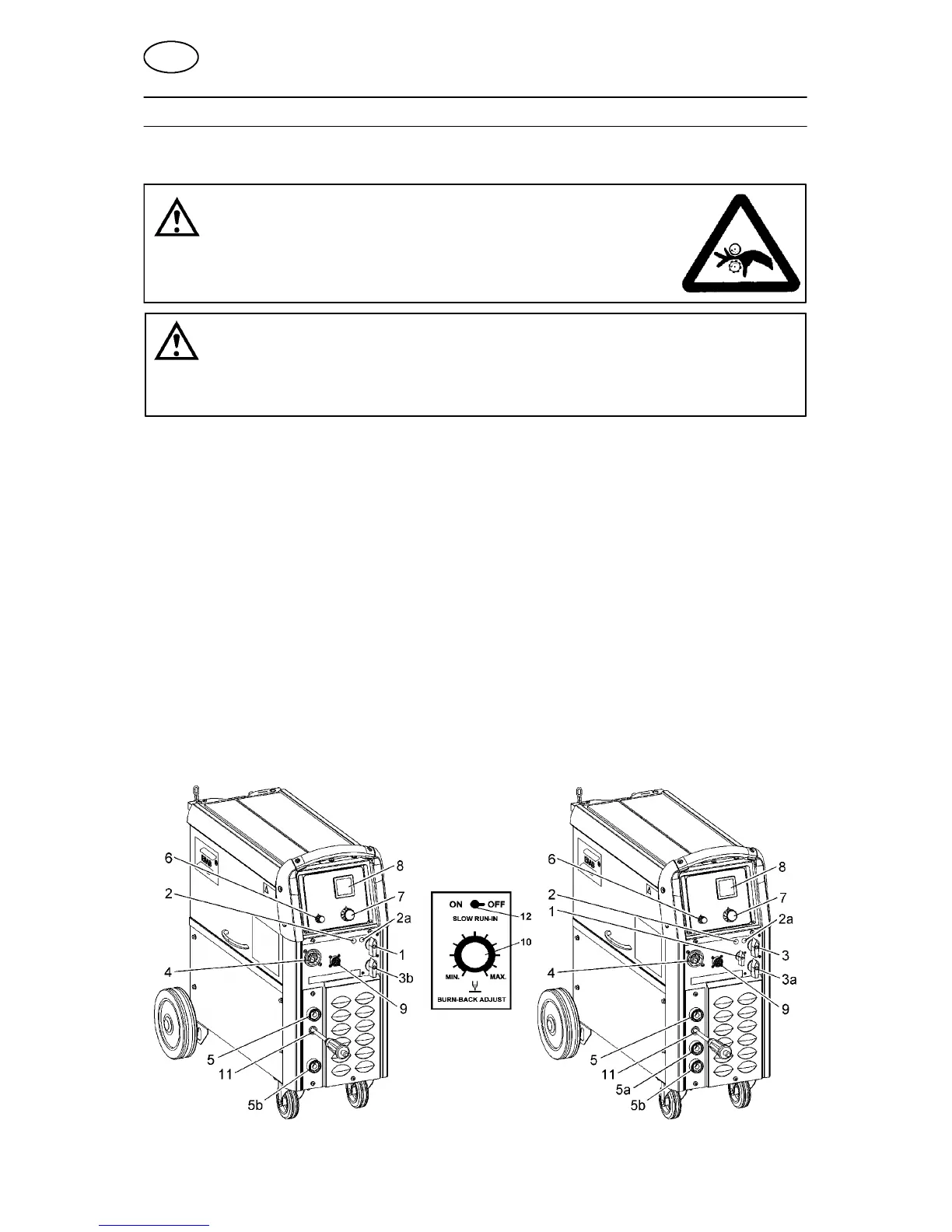

6.1 Connection and control devices

1 Mains supply switch 5b Connector [--], low inductance, for welding gun

or return cable (welding polarity change--over)

2 Orange indicating lamp, overheating 6 Knob for spot welding -- ON/OFF and time set-

ting

2a White indicating lamp “ON” 7 Knob for wire speed setting

3 Welding voltage switch, 7 steps (fine) 8 Digital instrument -- V/A

3a Welding voltage switch, 3 steps (coarse) 9 Connector for ”spool--on gun” (control wire)

3b Welding voltage switch, 12 steps 10 Knob for burn--back time setting

(located in wire feeder compartment)

4 EURO -- connector for welding gun 11 Cable with plug, connected to the welding gun

connector (welding polarity change--over)

5 Connector [+] for welding gun or return

cable (welding polarity change--over)

12 Creep start switch

(located in wire feeder compartment)

5a Connector [--], high inductance, for welding gun or return cable (welding polarity change--over)

208/230V 208/230/460/575V

GB

Loading...

Loading...