terminations on the element. Rewire the immersion heater. Close and secure terminal cover then the refill the

unit.

9.5 Refilling the System:

DO NOT switch on the immersion heater(s) or heat pump part of the unit until the system has been

completely refilled. Close the drain tap. With the hot tap open, turn on mains water supply.

When water flows from the hot tap allow to flow for a short while to purge air and to flush through any

disturbed particles. Close the hot tap and then open successive hot taps in system to purge any air. The

electrical supply can then be switched on.

9.6 Log Book:

Please complete the log book supplied with the Ecocent, stating what has been done, the date of the

service and the name/contact details of the servicing engineer.

9.7 Maintenance Requirements:

There are no formal annual maintenance requirements. However, it is advisable to check annually:

a) That the pressure and temperature relief valve is still functioning well by turning the plastic black

cap around to make sure that water comes out of the valve when the clack cap is turned.

b) Filters for debris.

c) That the air outlet to outside to make sure that it is clear from foliage, nests, etc.

Please note that the top cover of the Ecocent can be removed by a suitably qualified engineer/ plumber so that

the evaporator can be cleaned of dust and debris.

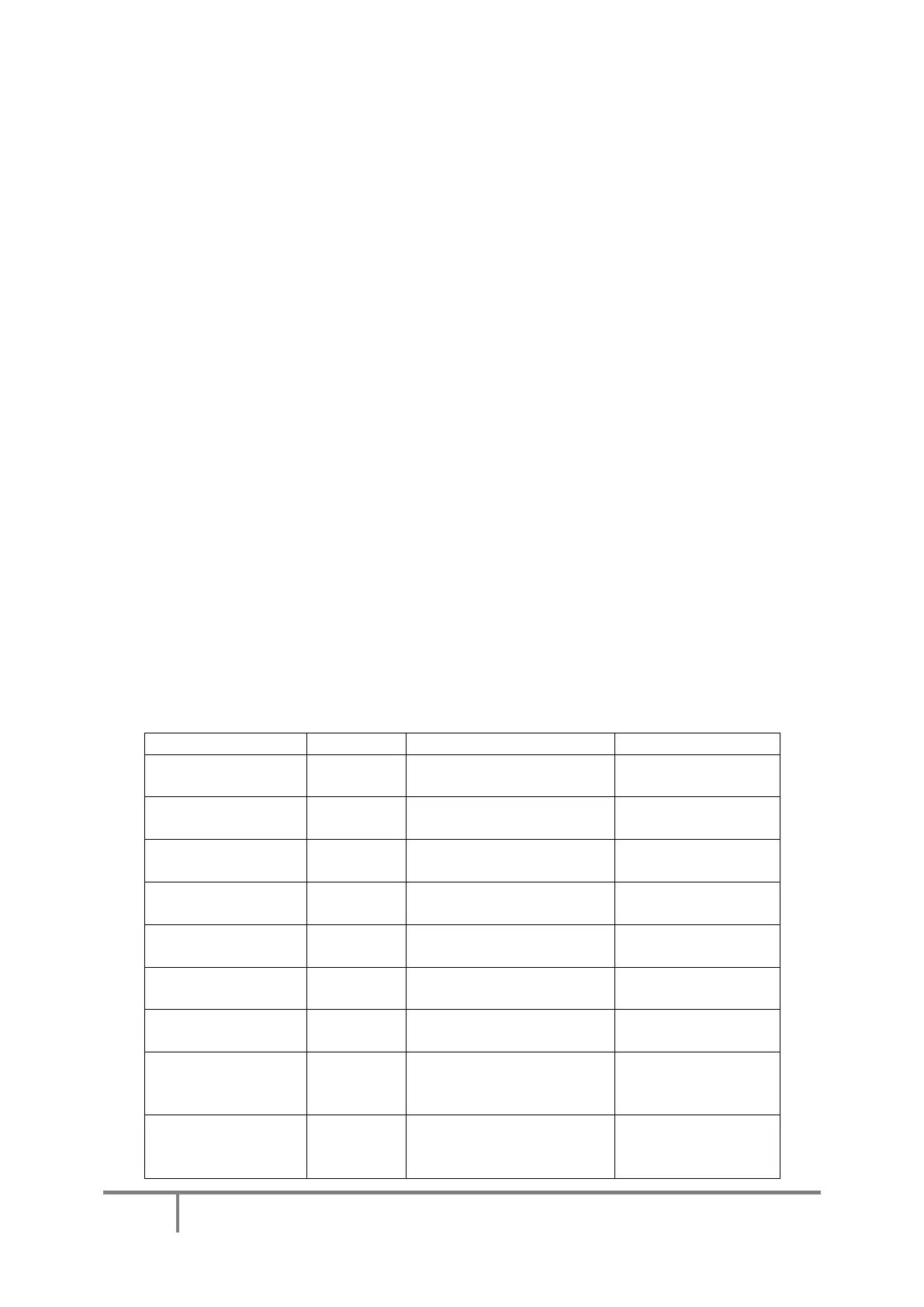

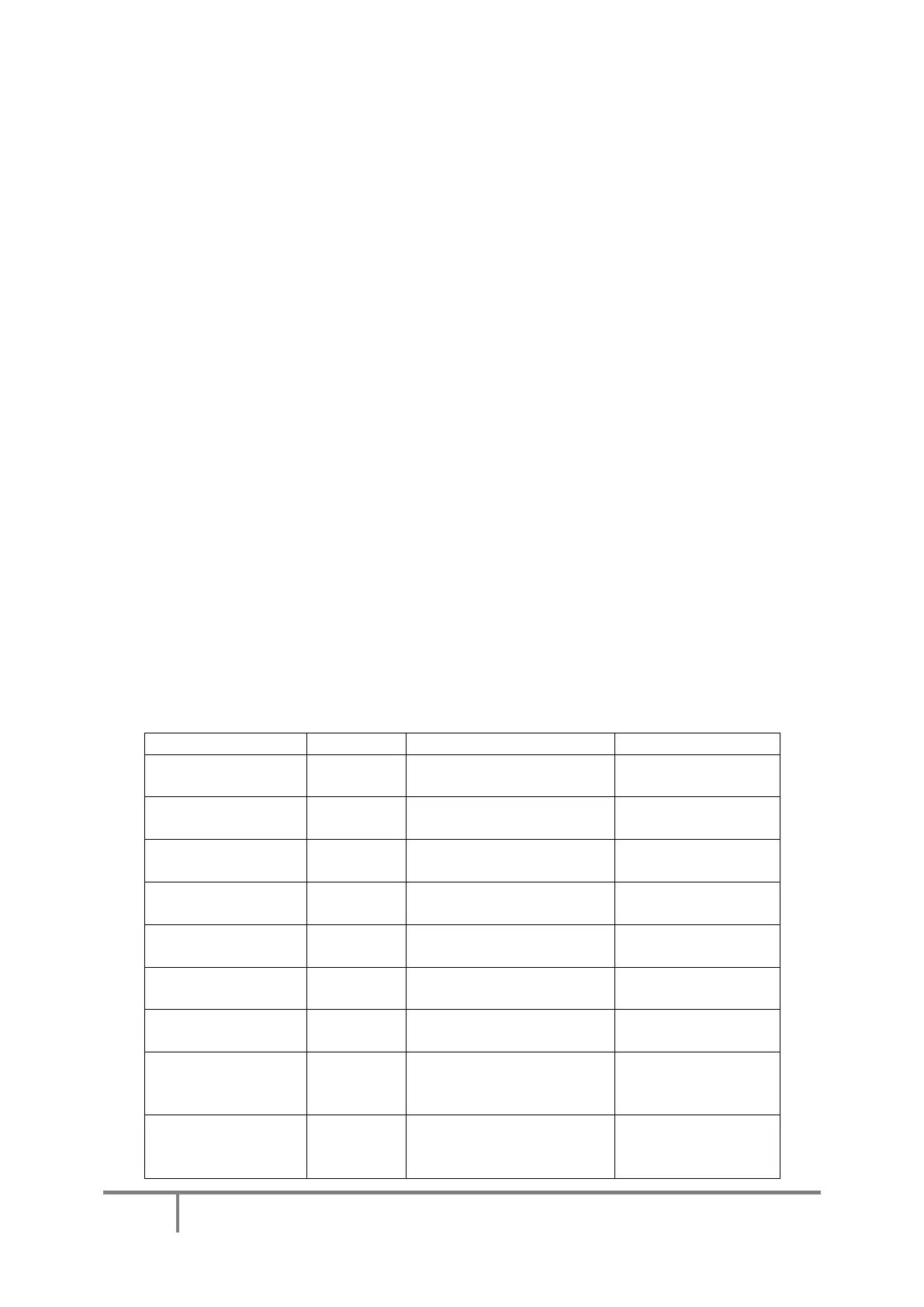

10.0 FAULTS

10.1 Simple Fault Finding

The following table is a list of simple faults and actions that can be taken to clear them. Diagnosis, testing and

repair should be carried out by a suitably qualified an experienced engineer/plumber.

Bottom water temp.

sensor failure.

Sensor is open or short-

circuit.

Check sensor and

change if necessary.

Top water temp

sensor failure.

Sensor is open or short-

circuit.

Check sensor and

change if necessary.

Ambient temp

sensor failure.

Sensor is open or short-

circuit.

Check sensor and

change if necessary.

Coil temp sensor

failure.

Sensor is open or short-

circuit.

Check sensor and

change if necessary.

Refrigerant absorb

sensor failure.

Sensor is open or short-

circuit.

Check sensor and

change if necessary.

Anti-freeze temp

senor failure.

Sensor is open or short-

circuit.

Check sensor and

change if necessary.

Solar temp sensor

failure.

Sensor is open or short-

circuit.

Check sensor and

change if necessary.

High pressure

protection.

Exhaust pressure is too

high.

Check high pressure

switch and cooling

return circuit.

Suction pressure is too low.

Check low pressure

switch and cooling

return circuit.

Loading...

Loading...