25

10• MAINTENANCE

Your mower is tted with a maintenance counter (page 9). This is a

useful tool that will inform you on the servicing cycles of your mower.

It displays the hours of use remaining until the next service is due. A

service is indicated by the ashing of the hours and:

- one spanner for the 1st service or an intermediate service.

- 2 spanners for a complete service.

Each time the engine is switched on.

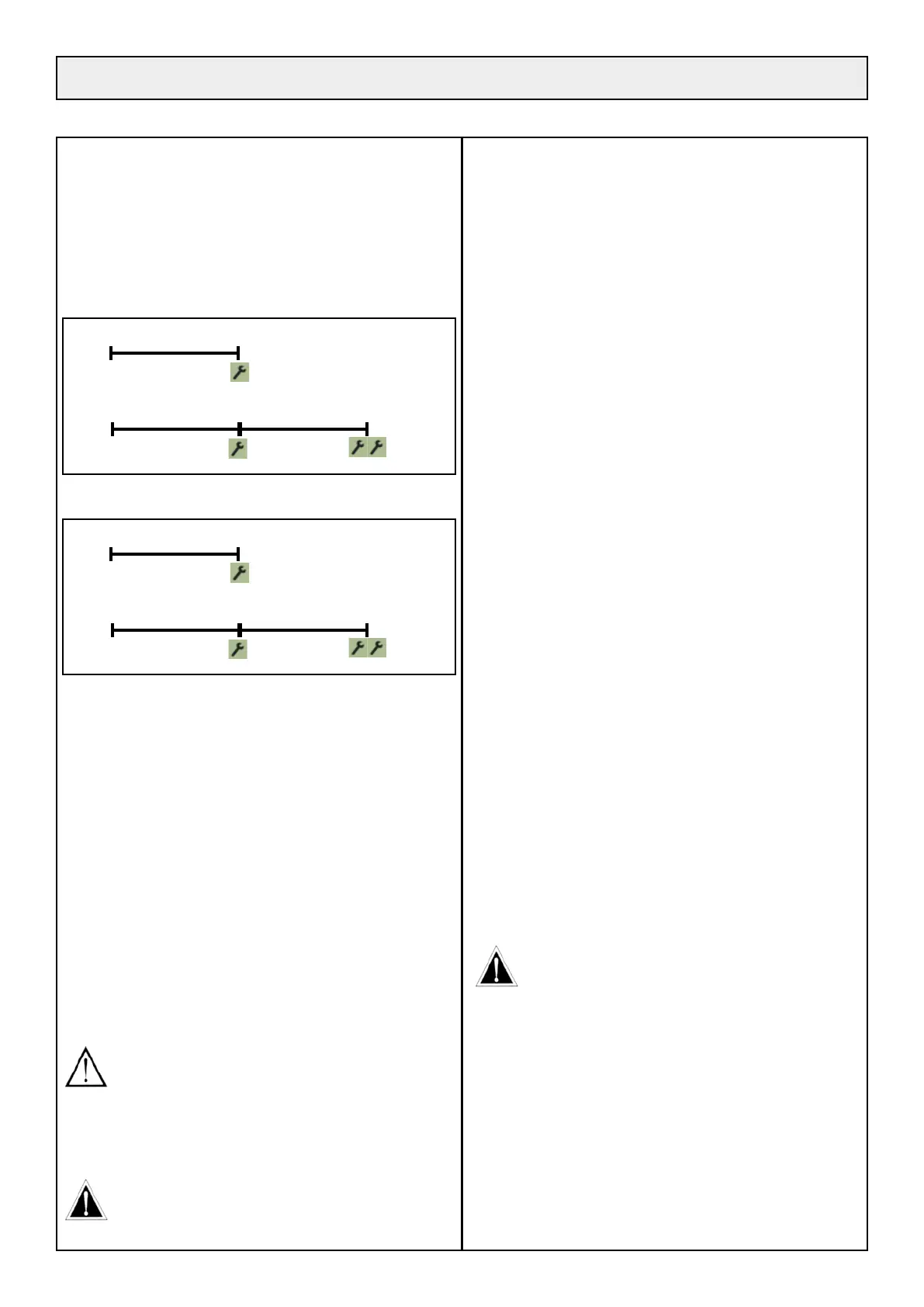

BPHP2 - BPHPX2

First service

20hrs 0hrs

Intermediate service Complete service

250hrs 125hrs 0hrs

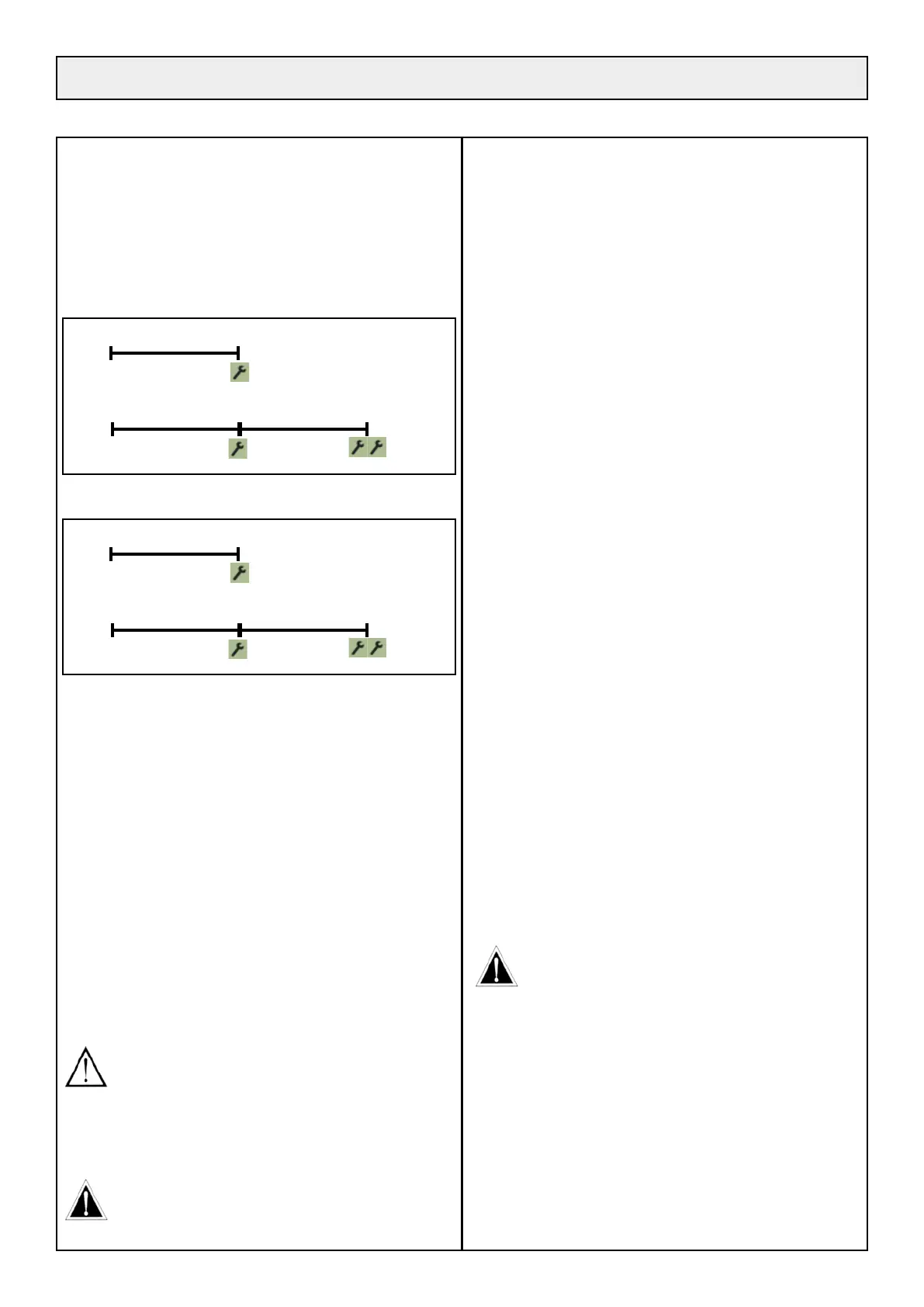

HVHP - HVHPX - BVHP - BVHPX

First service

10hrs 0hrs

Intermediate service Complete service

200hrs 100hrs 0hrs

REMARKS:

- If you do not have the tools or skills necessary, please contact your

dealer.

- It is strongly recommended that you strictly respect the service fre-

quencies.

After re-initialising at 0hrs, the spanner(s) stop ashing and the counter

displays 250hrs for diesel engine mowers and 200hrs for petrol engine

mowers.

After re-initialising at 125hrs for diesel engine mowers and 100hrs

for petrol engine mowers, spanner(s) stop ashing and the countdown

continues.

RE-INITIALIZATION:

after each service, remove the connector

(a picture 20) and connect the other connector (b) for a few seconds. To

do this, unscrew the plastic nuts (c) on the comfort counter and take it

out through the top of the console.

CAUTION: If the intermediate service has not been done

before the counter displays 62.5 hrs, do the complete service

immediately. In this case after re-initialization, the counter

will return to 250 hrs for diesel engine mowers and 200h

for petrol engine mowers. After re-initialization, reconnect

connector (a picture 20). If you do not, the indicator lights

and counters will no longer work.

LIFTING YOUR MACHINE

If you need to carry out some work underneath the machine

that requires raising it off the ground, we recommend the use

of a lift table able to take the weight of your machine.

10•1 ENGINE MAINTENANCE

10•1•1 CHECK THE ENGINE OIL LEVEL (each

time you use the machine)

• Place the mower on a horizontal surface.

• Open the engine hood and the intake pipe (paragraph 9•1 - page 23).

• Clean around the dipstick opening.

• Remove the dipstick: a picture 21a for Perkins motor - a picture 21b

for Briggs & Stratton motor.

• The oil level must be kept between [MINI] and [MAXI] at all times.

If necessary, top up with diesel engine oil 15W40 (BPHP2, BPHPX2)

ref. ETESIA 29591 (2l can), or with 10W40 grade oil (HVHP, HVHPX,

BVHP and BVHPX) ref. ETESIA 38383 (2l can). Do not ll above the

[MAXI].

10•1•2 ENGINE OIL CHANGE

BPHP2 AND BPHPX2

After the initial 20-hour service, the oil must be changed every 500

hours or at least once a year.

HVHP, HVHPX, BVHP AND BVHPX

After the initial 10-hour service, the oil must be changed every 100

hours or at least once a year.

• Run the engine to heat up the oil.

• Place the machine on a horizontal surface.

• Stop the engine, remove the ignition key. Wear gloves.

• Place a sufciently large recipient underneath the engine drain screw

(a picture 22).

• Unscrew the screw or the drain tap and let the used oil run out into

the recipient.

• Clean and screw back the screw or the drain tap.

• Clean around the ller hole to avoid any impurities getting into the

engine.

• Slowly pour in the new fuel engine oil (capacity: see technical

characteristics) - For models BPHP2 and BPHPX2 Etesia

recommends SHELL Rimula X 15W40 (ref. 29591), and for HVHP,

HVHPX, BVHP and BVHPX ETESIA recommends 10W40 grade

oil (ref. 38383).

• Check the oil level using the dipstick. The level must reach the [MAXI]

mark without going over it.

CAUTION! Take great care when emptying hot oil. Never

touch the exhaust pipe, the cylinders or the rocker cover as

you could burn yourself.

• Check that the drain screw is tight and there are no leaks and close

the engine cover.

• Take the used oil to an approved collection point.

10•1•3 CHANGE THE ENGINE OIL FILTER

• Change lters during each engine oil change.

PERKINS MOTOR

• Open the engine hood, remove the engine cooling radiator inspection

trap and open the right hand side cover and the suction duct (a picture

23a) for access to the lter (b).

Loading...

Loading...