30

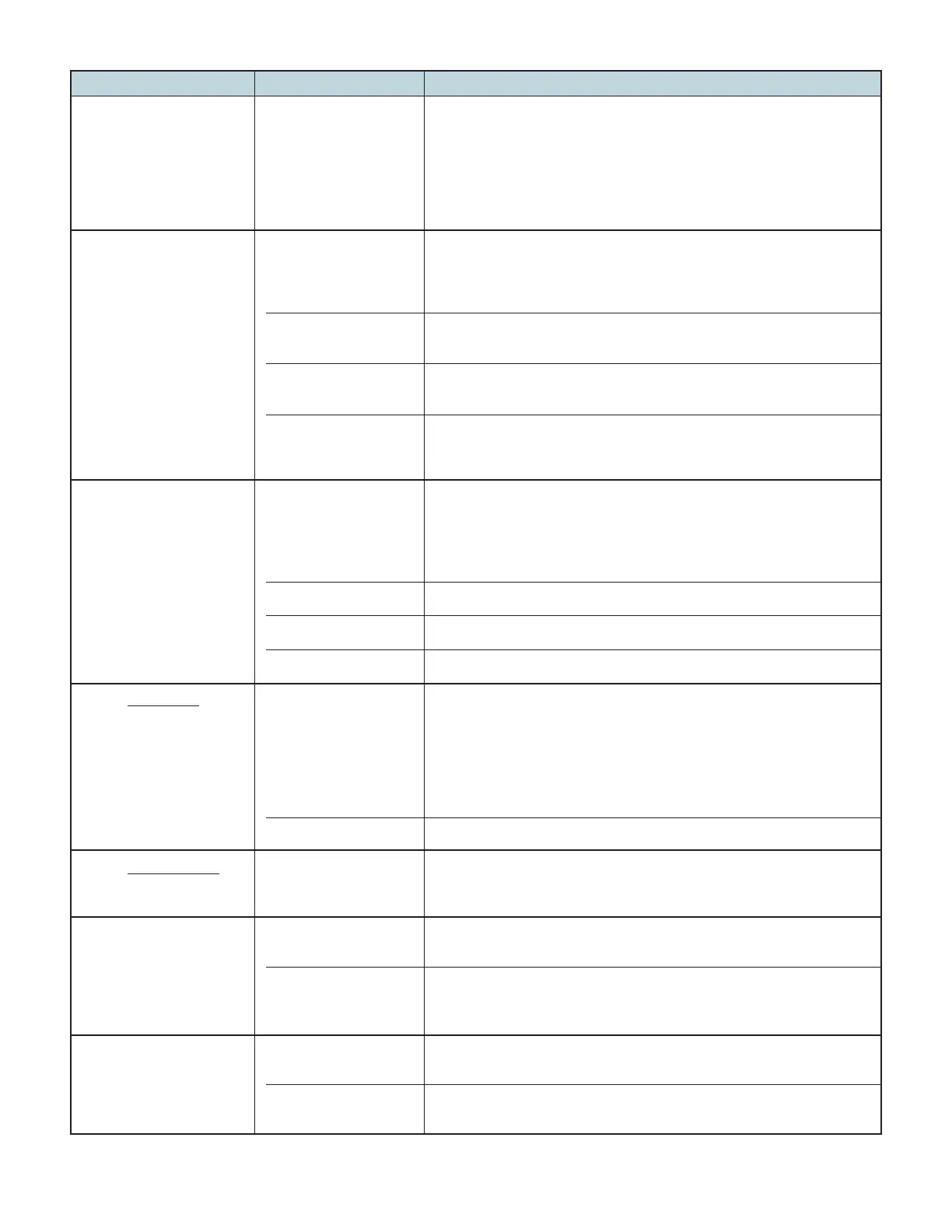

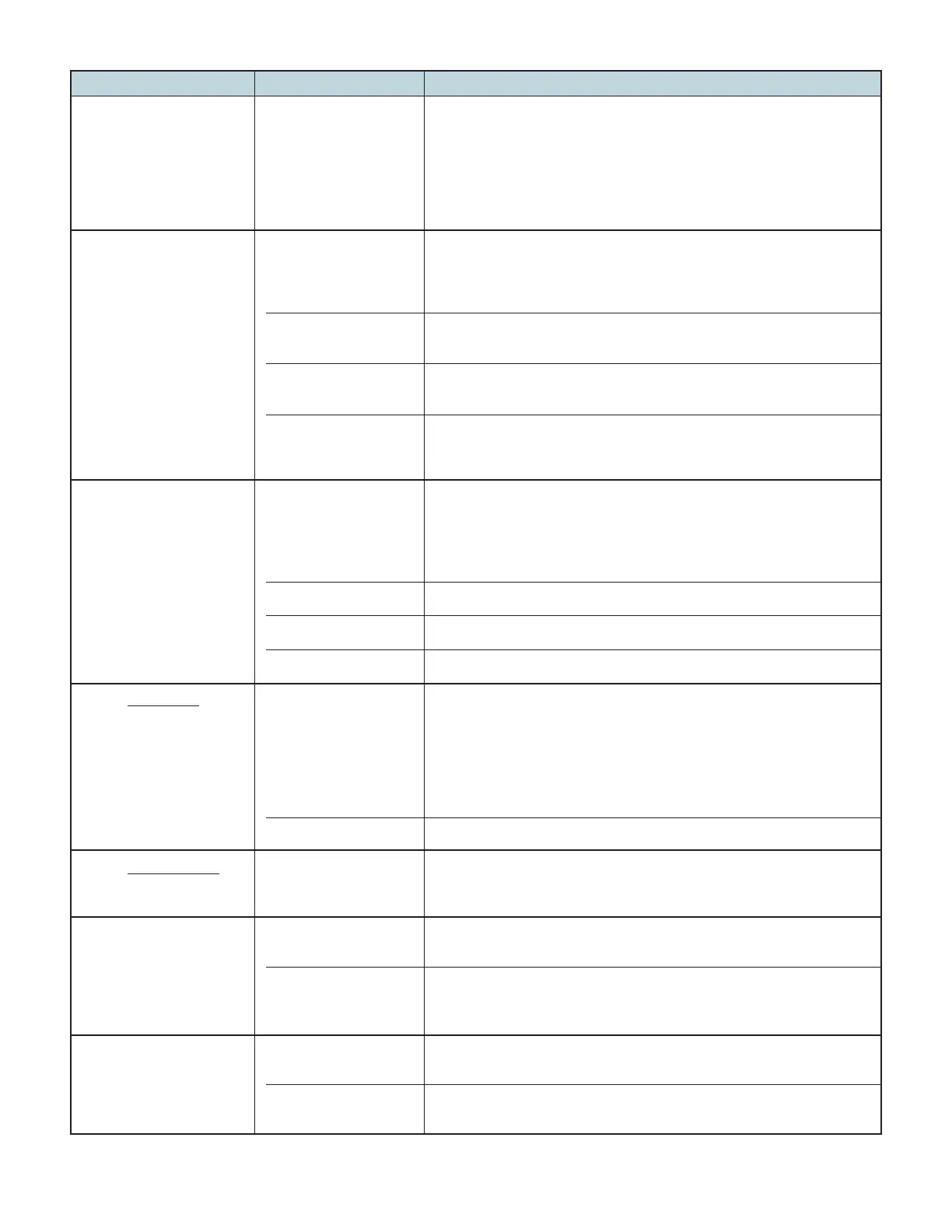

Problem Possible Cause Remedy

Improper water treatment,

insufficient bleed rates or

excessive cycling of the

fan motors, or high

concentrations of solids in

water.

Initial start-up

Mechanical failure

Electrical issue

Misconception of head

increase or decrease

Make-up water pressure

too high

Debris in solenoid

Frozen float ball

Float ball is full of water

This can happen on

forced dra units due to

the positive pressure in

the casing section.

Overflow connection has

not been piped at all or

properly

Incorrect water level

This is normal

Problem with make-up

line.

If multi-cell unit, there

may be an elevation

problem.

Electronic Water Level

Control

Float Ball not set correctly

Scale should not be removed using a power washer or wire brush

because it could damage the louvers. Remove the louver assemblies and

let them soak in the cold water basin of the unit. The water treatment

chemicals in the unit will neutralize and dissolve the buildup of scale.

NOTE: The time required for soaking the inlet louvers depends on

the severity of the scale buildup.

NOTE: This assumes chemicals are being used.

If the unit has only run for a few hours, the pump may overamp until the

pump wear ring has worn in. In this case, it would only be small

percentages, not 15 or 20%. Normally, aer a few hours, the pump amp

readings will reduce and level off.

Verify that the pump can turn freely by hand. If not, pump most likely

needs to be replaced.

Verify that the pump has been wired properly. Verify that the voltage

supplying the pump is correct.

NOTE: Increase or decrease in pump flow as a result of clogged

or blown out nozzles or headers should NOT cause the pump to

over amp.

Mechanical make-up valve water pressure must be between 20 and

50psi. If pressure is too high, the valve will not close. A pressure reducing

valve can be added to lower the pressure. For the 3 and 5 Probe

Electronic Water Level Control Package, the electrical actuator has a 5 to

125 psi water pressure requirement.

Clean out solenoid of any debris.

Inspect, and if so, float or valve may need to be replaced.

Check ball for leaks and replace.

Pipe the overflow with a P-trap to an appropriate drain.

Verify actual operating level versus O&M recommended levels

This is normal. The bleed line for the unit is piped to the overflow

connection

Refer to Makeup Valve or Electronic Water Level section.

Make sure that multi-cell units are installed level to one another. If they

are not, it can cause overflowing in one cell.

See EWLC Section

Adjust float ball up or down to obtain proper water level.

NOTE: The float ball is set to the operating level at the factory.

Scaled Inlet Louvers on

AT Units

Overamping Pump

Motors

Makeup Valve Will Not

Shut Off

Water Constantly

Blowing Out Overflow

Connection

Water Intermittently

Blowing Out Overflow

Connection

Cold Water Basin

Overflowing

Low Pan Water Level

Loading...

Loading...