10

ATC-E, ATC-ES, ATWB, eco-ATWB and eco-ATWB-E Evaporative Condensers and Closed Circuit Coolers

Assembly of the Coil/Fan Section to the Basin (Cont.)

Use of Drift Pins for Final Positioning

Drift pins are tools used to align holes in the flanges of the

u

pper and lower sections of the unit prior to final fastening. By

the time drift pins are needed, the lower section of the unit has

already been anchored to its support structure. The sealer tape

has been laid down on the lower section’s flanges, and the

upper section is now hovering over the lower section.

A drift pin should be driven in to each of the corner bolt holes

such that the upper and lower flanges are aligned as best as

possible with sideways motion restricted.

On units which are longer than 12’ (“L” > 12' [3.7m]), a drift pin

should be used at an intermediate pair of bolt holes in the

rigging seam to allow for proper alignment.

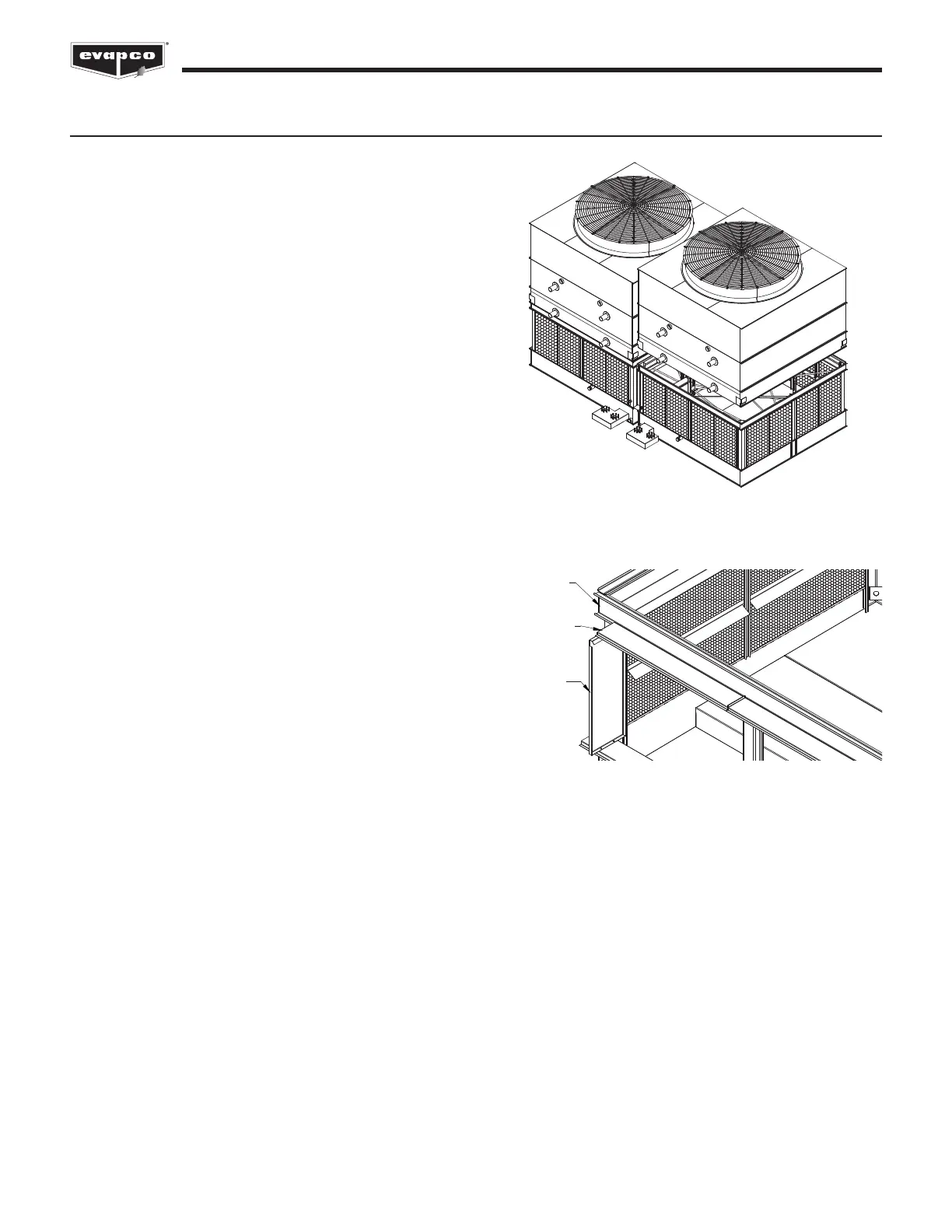

VERTICAL

SPLASH

GUARD

PAN SECTION

SIDE PANEL

FILLER CAP

CHANNEL

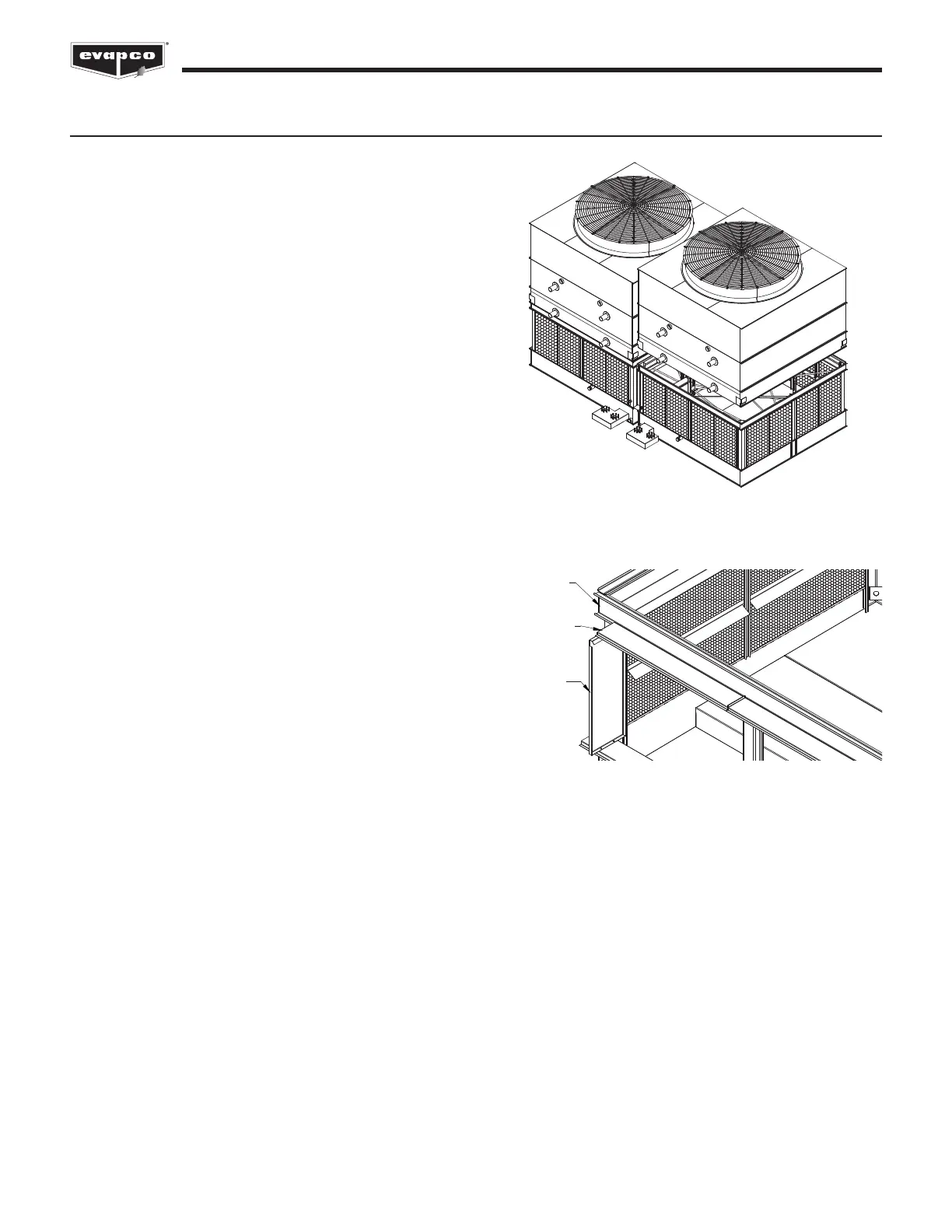

Figure 9 - Mating Upper Section to Basin Section

Figure 10 - Filler Cap Channel Assembly

Notes:

For multi-cell units, the side flanges located in between cells

can be accessed from inside the unit.

Bolts can be driven upward through the mating flanges if

access is restricted.

All rigging hardware is provided by EVAPCO. Drift pins are

by others.

Loading...

Loading...