7

Operation and Maintenance Instructions

At initial start up or after the unit has been drained, the unit must

be filled to the overflow level. Overflow level is above the normal

operating level and accommodates the volume of water normally

in suspension in the water distribution system and the riser piping.

The water level should always be above the strainer. Check by

running the pump with the fan motors off and observing the water

level through the access door or remove the air inlet louver.

Water Make Up Valve

A mechanical float valve assembly is provided as standard

equipment on the evaporative cooling unit (unless the unit has

been ordered with an optional electronic water level control

package or the unit is arranged for remote sump operation).

The water level in the basin is adjusted by repositioning the

float and all-thread using the wing nuts.

The make up valve assembly should be inspected monthly

and adjusted as required. The valve should be inspected

annually for leakage and if necessary, the valve seat should

be replaced. The make up water pressure for the mechanical

valve should be maintained between 140 and 340 kPa.

Drift Eliminators

Check the drift eliminators quarterly to make sure the drift

eliminators are still in the correct position and not clogged

by any debris. If required after inspection, drift eliminators

must be removed, cleaned and reinstalled correctly.On forced

draft models, the worker must use personal precautions

and adequate safety measures against the risk of a fall,

in accordance with local regulations. Remove one or two

eliminator sections from the top of the unit, protect the fill by

use of a hard board before entering the unit and walking on

the fill. Never walk on the eliminators! Once standing on the

fill, the remaining drift eliminators can be removed. On induced

draft models, lifting handles are provided along the top

layer of eliminators. Remove one or two eliminator sections,

protect the fill by use of a hard board before entering the unit

and walking on the fill. Never walk on the eliminators! Once

standing on the fill, the remaining drift eliminators can be

easily removed through the access door.

Pressurized Water Distribution Systems

Check the water distribution system monthly to make sure it

is operating properly. Always check the spray system with the

pump on and the fans off (locked and tagged out).

On forced draft models, remove one or two eliminator sections

from the top of the unit and observe the operation of the water

distribution system.

On induced draft models, lifting handles are provided along

the top layer of eliminators. Eliminators can be easily removed

from the access door and the distribution system observed.

The diffusers are essentially non-clogging and should seldom

need cleaning or maintenance.

If the water diffusers are not functioning properly, it is a sign

that the pan or system strainer has not been working properly

and that foreign matter or dirt has accumulated in the water

distribution pipes. The nozzles can be cleared by taking a

small pointed probed and moving it rapidly back and forth in

the diffuser opening, with the pump(s) running and the cooling

load and fan(s) off.

If an extreme build-up of dirt or foreign matter occurs, remove

the end cap in each branch to flush the debris from the header

pipe. The branches or header can be removed for cleaning,

but do so only if necessary. Check the strainer in the pan to

make sure it is in good condition and positioned properly so

that cavitation or air entrainment does not occur.

All Evaporative Condensers and Closed Circuit Coolers, except

the ESWA Closed Circuit Cooler, are supplied with ZM II

®

spray

nozzles as standard. The ZM II

®

spray nozzles do not need to

be oriented a specific way to achieve proper coil coverage.

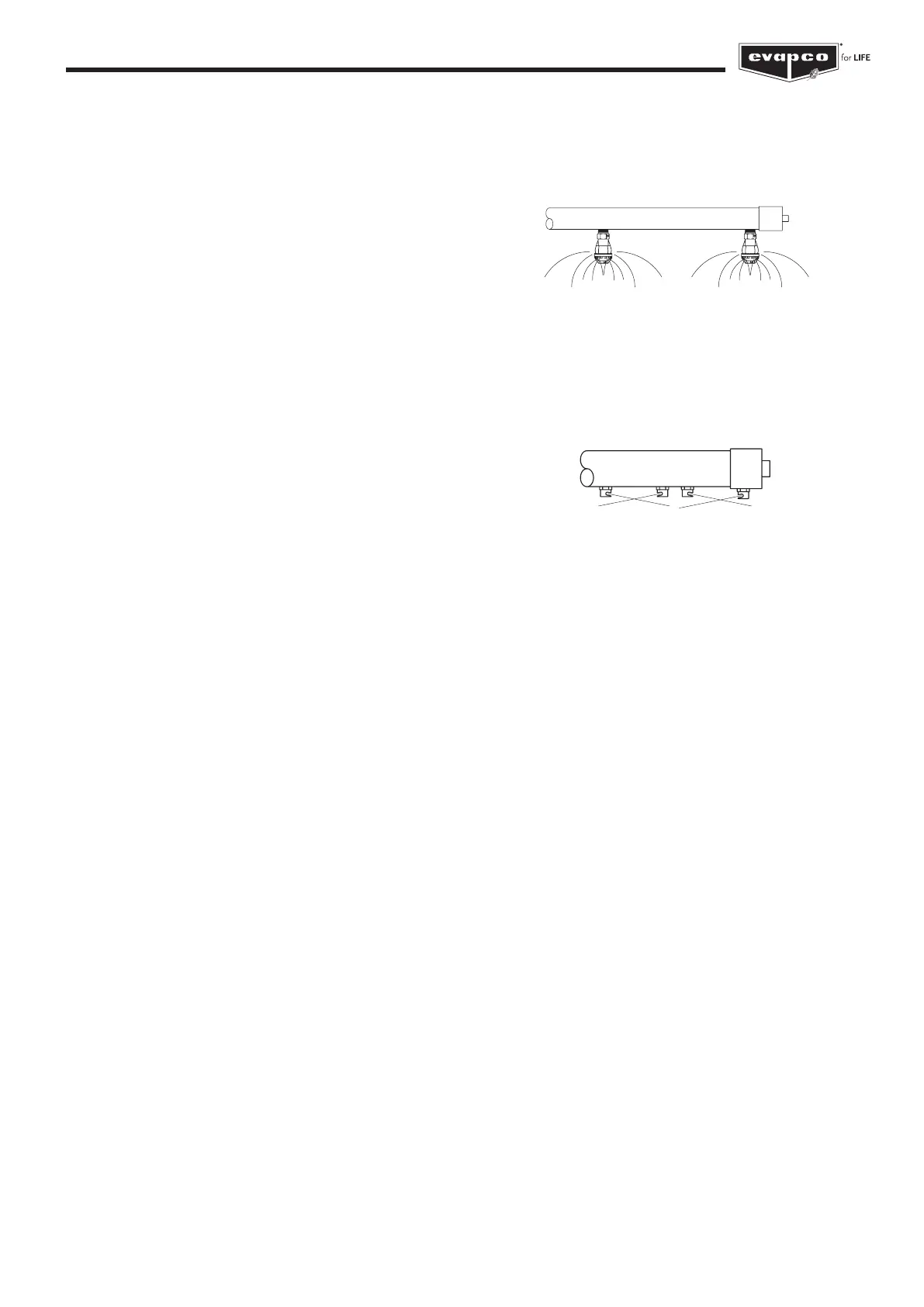

Figure 1 shows the proper spacing of the ZM II

®

spray nozzles.

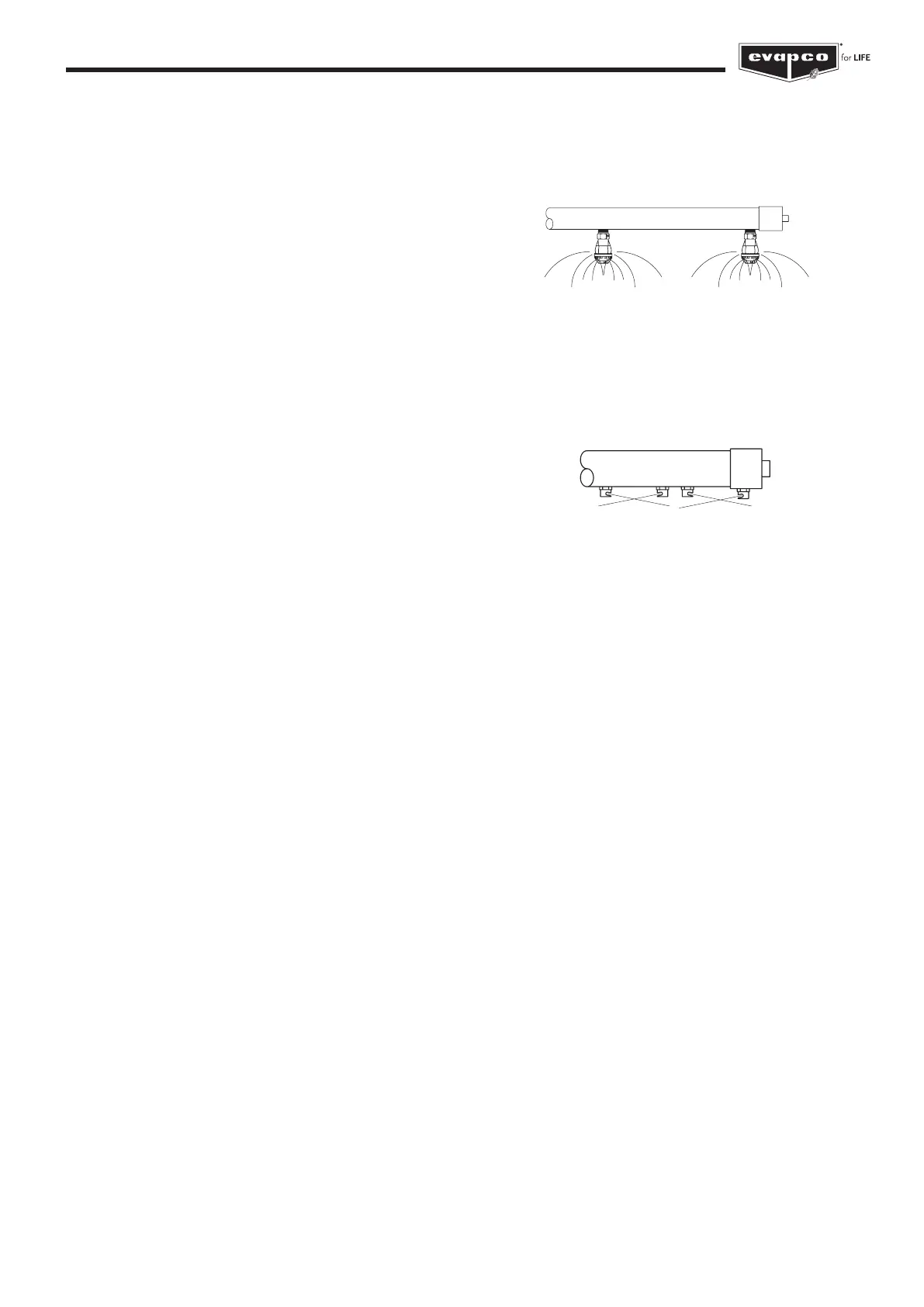

For the ESWA, wide orifice water diffusers are supplied. When

inspecting and cleaning the water distribution system, always

check that the orientation of the water diffusers is correct as

shown in Figure 2.

Bleed-Off Valve

The bleed-off valve, whether factory or field installed, must be

checked weekly to make sure it is functioning and set properly.

Keep the bleed-off valve wide open unless it has been

determined that it can be set partially open without causing

scaling or corrosion.

Pump (When Supplied)

The pump and pump motor should be lubricated and serviced

in accordance with the pump manufacturer’s instructions.

The recirculation pump should not be used as a means

of capacity control, and should not be cycled frequently.

Excessive cycling can lead to scale build-up, and reduce wet

and dry performance.

Note: for the eco-ATW(E), please consult the Sage

2

and Sage

3

manual.

Coils

Contact Evapco in case of damage to the pressure vessel.

Do not affect the integrity of the pressure vessel without

approval of Evapco.

Evaporative Coil(s)

Check coil surface periodically, but at least twice a year. Inspect

the coil surface for scale and/or corrosion.

Dry Coils (optional)

Depending on outdoor conditions and unit type, the dry coil

should be inspected and cleaned at least twice a year. If the

unit is located near trees, construction, etc., the required

cleaning may be more frequent. The coil should be visually

inspected monthly along with inlet louvers and inlet screens.

The best cleaning solution for the dry coil is plain water. If the

coil has maintained and cleaned at regular intervals, water is

sufficient to remove dirt and debris from the fins. Heavy build

up on the exterior of the fins can be removed with a brush. If a

pressure washer is used, make sure the equipment is set to a

low pressure setting and that the nozzle is set to the fan spray,

not stream, otherwise damage to the fins could result.

Figure 1 - ZM II

®

Spray Nozzle Orientation.

All Coil Products except the ESWA

Figure 2 - Proper Water Diffuser Orientation

(2A Nozzles) ESWA Models

Loading...

Loading...