www.evco.it

2/2

EV3 200 Web | Controller - Gateway for a network of up to 10 devices

EVCO S.p.A. | EV3 200 Web | 1043W24A3.00

EVCO S.p.A.

Via Feltre 81, 32036, Sedico (BL) ITALIA

Telephone: 0437 8422 | Fax: 0437 83648

Email: info@evco.it | Web: www.evco.it

Disclaimer

This document is the exclusive property of EVCO. It contains a general description and/or a description of

the technical specifications for the services offered by the products listed herein. This document should not

be used to determine the suitability or reliability of these products in relation to specific user applications.

Each user or integration specialist should conduct their own complete and appropriate risk analysis, in

addition to carrying out a product evaluation and test in relation to its specific application or use. Users

can send us comments and suggestions on how to improve or correct this publication.

Neither EVCO nor any of its associates or subsidiaries shall be held responsible or liable for improper use

of the information contained herein.

EVCO has a policy of continuous development. Therefore, EVCO reserves the right to make changes and

improvements to any product described in this document without prior notice.

The technical data in this manual is subject to change without prior notice.

Consider the environment

Please consider the environment before printing this document.

Disposal

The device must be disposed of in accordance with local regulations regarding the

collection of electrical and electronic appliances.

For further information, consult the user manual p/n 114J500E4

downloadable from the website

www.evco.it or scan the QR CODE.

SCAN THE QR CODE AND

READ THE USER MANUAL!

ELECTRICAL CONNECTIONS

DANGER

RISK OF ELECTRIC SHOCK, EXPLOSION OR ELECTRIC ARC

• Various product components, including the printed circuits, run at hazardous voltage levels.

• Only use electrically insulated and suitably calibrated measuring devices and equipment.

• Do not open, disassemble, repair or modify the product.

• Before handling the product, make sure you are wearing all the necessary personal protective

equipment (PPE).

• Do not expose the equipment to liquids or chemicals.

• Use this device and all parts connected to it at the specified voltage only.

• Do not use this equipment for critical safety functions.

FAILURE TO FOLLOW THESE INSTRUCTIONS WILL RESULT IN DEATH OR

SERIOUS INJURY.

DANGER

RISK OF ELECTRIC SHOCK AND FIRE

• Do not use the device with loads greater than those indicated in the technical specifications.

• Do not exceed the temperature and humidity ranges indicated in the technical specifications.

FAILURE TO FOLLOW THESE INSTRUCTIONS WILL RESULT IN DEATH OR

SERIOUS INJURY.

WARNING

MALFUNCTIONING OF THE EQUIPMENT

• Perform the wiring carefully, in compliance with electromagnetic compatibility and safety

requirements.

• Do not operate the product with unknown or incorrect settings or data.

• Make sure the wiring is correct for the final application.

• Use shielded cables for all I/O signal and communication cables.

• Minimise the length of the connections as much as possible and avoid winding the cables

around electrically connected parts.

• The signal cables (analogue and digital inputs, communication and corresponding power

supplies), power cables and power supply cables for the device must be routed separately.

• Before applying the power supply, check all the wiring connections.

• Do not connect wires to unused terminals and/or to terminals labelled “No connection “(N.C.)”.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN DEATH, SERIOUS

INJURY, OR EQUIPMENT DAMAGE.

Suitable wiring for power supply and I/O SELV

Passo 5,08 mm (0.199 in.)

Ø 3.5 mm (0.14 in.)

mm

2

AWG

0.2…2.5

24…14

0.2…2.5

24…14

0.25…2.5

22...14

2 x 0.25…1

2 x 22…18

2 x 0.2…1.5

2 x 24…16

2 x 0.2…1

2 x 24…18

2 x 0.5...1.5

2 x 20...16

mm

in.

7

0.28

C

0.5...0.6

4.42...5.31

N•m

lb-in

0.25…2.5

22...14

NOTICE

INOPERABLE DEVICE

• When connecting the probes, the digital inputs and the power supply, use cables with a

maximum length of 10 m (32.80 ft).

• When connecting the power supply of the controller and the relay outputs, use cables with

a maximum length of 10 m (32.80 ft.).

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT EQUIPMENT DAMAGE

.

DIMENSIONS

33 (1.30)

75 (2.95)

69 (2.71)

59 (2.32)

)

INSTALLATION

71

(

2.7

9)

29 (1.14)

mm (in.)

40 (1.57) 40 (1.57)

40 (1.57) 40 (1.57)

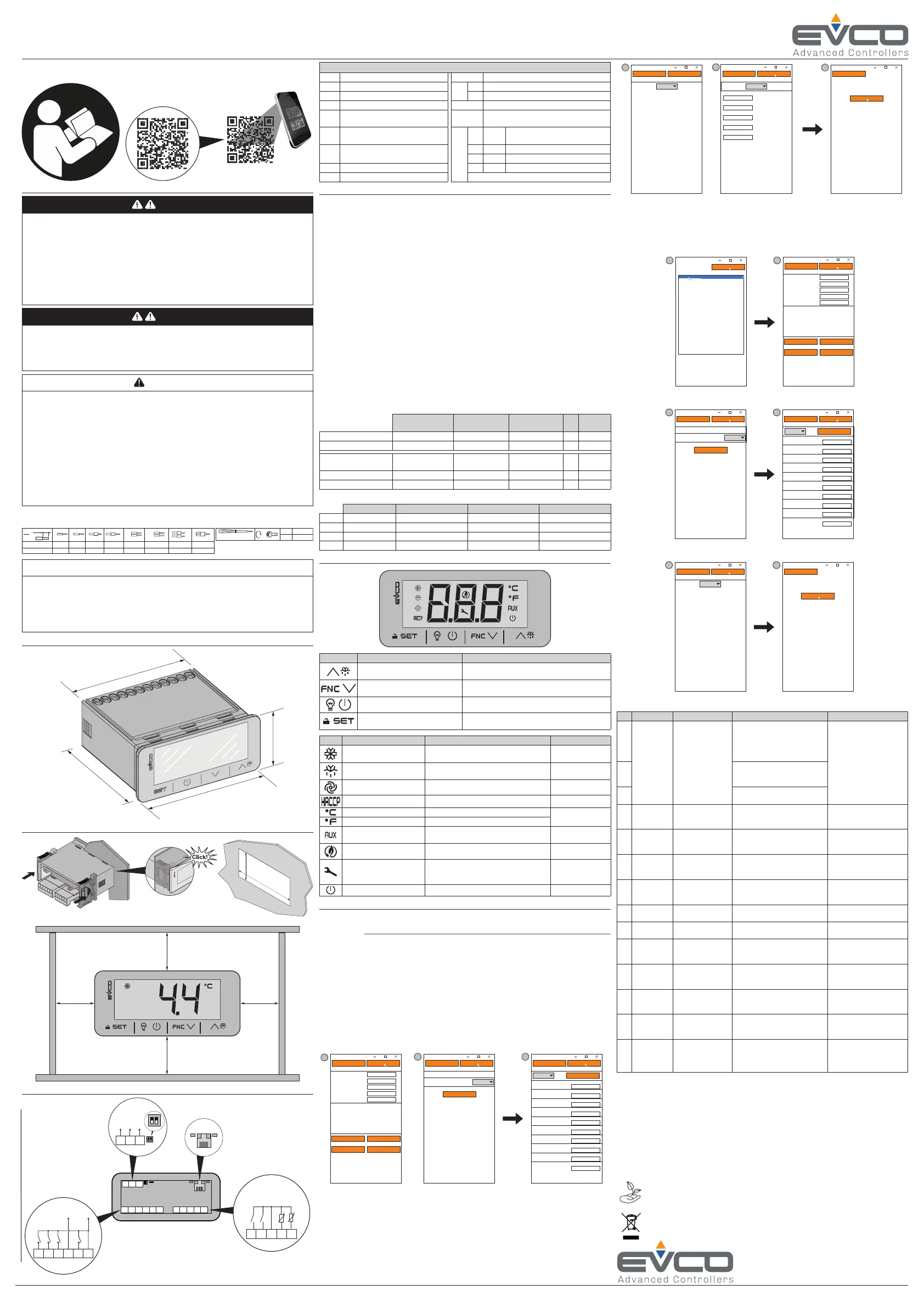

WIRING DIAGRAM

1 2 3 4 5 6

1

2

13 14 15

Out2

A+

Out4

Out3

Out1

Power Supply

Maximum 12 A

USB

LT

Pb1

Pb2

ID1

ID3

RS-485

EV3 200 Web

ON

1

2

1

2

13 14 15

RS-485

ETHERNET

ETHERNET

8 9 10 11 12

8 9 10 11 12

1 2 3 4 5 6

B- GND

LD3

LD1

LD2

LD4

ON

1

2

ON

1

2

LT

LT

TERMINALS

1-6 Relay output Out1 (Compressor) 13-14-15 RS-485 serial input

2-6 Relay output Out3 (Fans)

LT

1 ON = Termination resistor inserted

3-6 Relay output Out4 (Defrost) 2 Reserved

4-6 Power supply input USB USB 2.0 input for communication

5-6 Relay output Out2 (AUX)

ETHERNET

RJ45 connector to connect to Ethernet

serial port

8-10 Digital input ID1

LED

LD1 Red

Flashes with messages from

subnetwork

9-10

Digital input ID3 (if P4=0)

Probe input Pb3 (if P4 ≠ 0)

LD2 Green Stays on if connected to EPoCA

LD3 Red Stays on with Ethernet link-up

11-10 Analogue input Pb1 (Temperature) LD4 Green Stays on with Ethernet activity

12-10 Analogue input Pb2 (Evaporator) LED Spenti: No communication

TECHNICAL SPECIFICATIONS

The product complies with the following

harmonised standards:

EN60730-1 and EN60730-2-9

Device construction: Built-in electronic device

Device purpose: Operating control device

Type of action: 1

Pollution category: 2

Overvoltage category: III

Rated impulse withstand voltage: 4000 V

Power supply: 115...230 Vac, ±10%, 50/60 Hz

Consumption: 10 VA maximum

Ambient operating conditions: -10 ... 50 °C (14 ... 122 °F) 10 … 90 % RH non-condensing

Transportation and storage conditions: -20 ... 70 °C (-4 ... 158 °F) 10 … 90 % RH non-condensing

Software class: A

Environmental front protection: IP65

Clock (RTC): Built-in lithium battery

Clock drift: ≤ 60 s/month at 25 °C (77 °F)

Battery life: 30 days

Battery charging time: 24 h through device’s power supply

Data memory: 32 MB

Data memory per device: ~2.7 MB

OTHER TECHNICAL INFORMATION

Digital inputs: 2 voltage-free digital inputs

Analogue inputs for temperature: 2 analogue inputs for NTC probes

Digital output with non-hazardous voltage (SELV): 4 relay outputs

Serial: 1 Ethernet RJ45 10/100 MAC serial port

1 USB serial port

ANALOGUE INPUT FEATURES

Default

NTC 10 kΩ at 25

°C BETA 3435

PTC KTY 81-121

990 Ω at 25 °C

RH

Digital

input

Pb1

Probe Temperature

• --- --- ---

Pb2

Probe Evaporator

• --- --- ---

Range ---

-40...105 °C

(-40...220 °F)

--- --- ---

Resolution --- 0.1 °C (1 °F) --- --- ---

Input impedance --- 10 kΩ --- --- ---

DIGITAL OUTPUT FEATURES

Default Description Load (at 250 Vac) Type of load

Out1 Compressor SPDT 16 A Resistive

Out2 AUX SPDT 5 A Resistive

Out3 Fans SPDT 5 A Resistive

Out4 Not configured SPDT 8 A Resistive

USER INTERFACE

Key... Press once... Hold down...

• Scroll up through values

• Move within a menu

Activate manual defrost

• Scroll down through values

• Move within a menu

Access the FNC functions menu (functions activated

by key)

Manually activate the light relay Switch the device on/off (stand-by)

• Conrm values on the display

• Set the setpoint

Enter the parameter menu

Icon ON... Flashing... OFF...

Compressor ON

• Protection delay compressor ON

• Setpoint being changed

Compressor OFF

• Defrost ON

• Pre-dripping ON

• Defrost delay ON

• Dripping ON

---

Evaporator fans ON

Evaporator fan activation delay ON

Evaporator fans OFF

HACCP alarm saved New HACCP alarm recorded ---

Temperature displayed in °C ---

• Over-heating ON

• Over-cooling ON

Temperature displayed in °F ---

• AUX function ON

• AUX digital output ON

--- AUX function OFF

Energy saving ON --- Energy saving OFF

Compressor maintenance

request

• Parameters being changed

• Access to FNC menu (functions activated by key)

• Active connection with EVconnect

---

Device off --- Device on

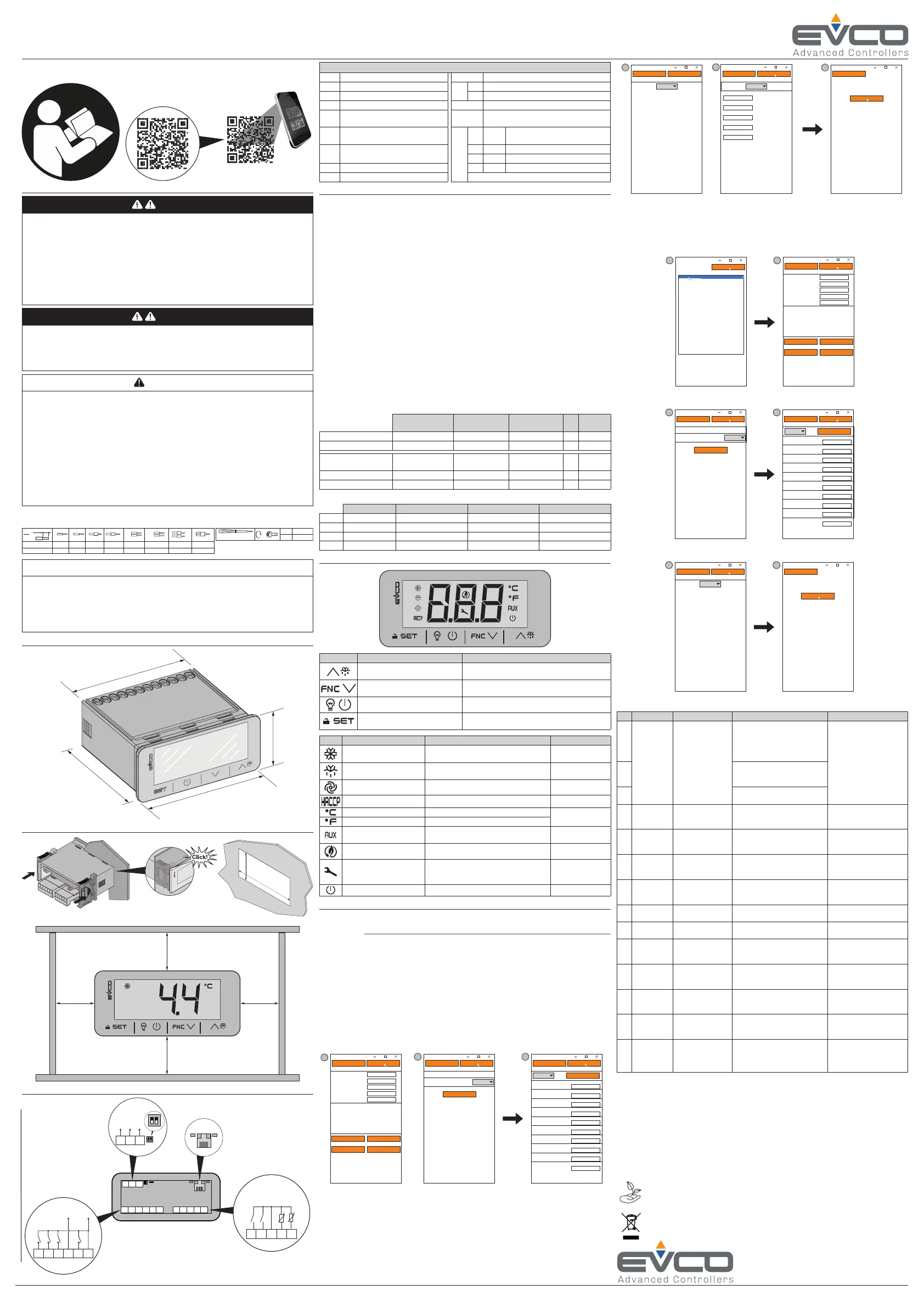

REMOTE COMMUNICATION CONFIGURATION

EV3 200 Web can be configured to connect with EPoCA in two different ways:

•

From a PC (Windows only) through EPoCA.exe (online/ofine) which can be downloaded from

the website: https://www.evco.it/assets/doc/EVCO-EV3200Web_congurator_for_EPoCA.zip

• From a smartphone/tablet using the EVLink Wi-Fi app.

In both cases, the devices must be visible on the local network. If the local network requires a

static IP address, configure using the micro-B USB cable.

If used in a subnetwork, configure the BLE parameter for every device from 1 to 10 before

searching on the network.

NOTE: For more information regarding the possible congurations of remote communication,

scan the QR code in this instruction sheet and read the user manual.

Conguration using PC (

Connecting using a micro-B USB cable)

1. Connect the micro-B USB cable from the PC to the device;

2. Make sure EPoCA.exe has been installed in the PC;

3. Boot up EPoCA.exe;

4. Set the Plant and Device data, save the conguration by pressing Save Cong. and continue

by pressing Next;

3

Next

Prev

1. Plant Configuration

EPOCA

Plant Name:

Plant Password:

Plant Category:

Device Name:

Serial Code:

Plant ID:

Build:

Last Reset:

Mac address:

Internet Status:

Save Config.

Export plant fileUpload plant file

Erase Config.

4 5

Next

Prev

2. Date and Time

EPOCA

Day, NN MM YYYY hh:mm:ss

Daylight saving time

Addr. 1

Off

Set local time

Next

Prev

3. Controllers

EPOCA

Autoaddress

Com1

On Line

On Line

Off Line

Off Line

Off Line

Off Line

Off Line

Off Line

Off Line

Off Line

Name Name

Name

Addr. 2

Addr. 3

Addr. 4

Addr. 5

Addr. 6

Addr.7

Addr. 8

Addr. 9

Addr. 10

Name

Name

Name

Name

Name

Name

Name

Name

Name

5. Set the date, time and local time used and press Next;

6. Set the name of the controllers connected via RS-485 to EV3 200 Web and press Next;

7. Set the type of IP address and press Next;

8. Press Congure to complete conguration of the device.

6 7

Next

Prev

4. IP Address

EPOCA

IP address:

Dynamic

Next

Prev

EPOCA

Configure

Next

Prev

4. IP Address

EPOCA

Static

IP address

Netmask

Gateway

Dns 1

Dns 2

0.0.0.0

0.0.0.0

0.0.0.0

0.0.0.0

0.0.0.0

6

Conguration using PC (Connecting using an Ethernet cable with connection to modem)

1. Make sure EPoCA.exe has been installed in the PC;

2. Boot up EPoCA.exe, the programme scans the local network (LAN) which the PC is

connected to to detect the devices;

3. Select the device to congure and press Next;

4. Set the Plant and Device data, save the conguration by pressing Save Cong. and continue

by pressing Next;

3 4

Next

Device selection

Device web page

EPOCA

EPOCAAXXXXX

Next

Prev

1. Plant Configuration

EPOCA

Plant Name:

Password:

Plant Category:

Device Name:

Serial Code:

Plant ID:

Build:

Last Reset:

Mac address:

Internet Status:

Save Config.

Export plant fileUpload plant file

Erase Config.

5. Set the date, time and local time used and press Next;

6. Set the name of the controllers connected via RS-485 to EV3 200 Web and press Next;

5 6

Next

Prev

2. Date and Time

EPOCA

Day, NN MM YYYY hh:mm:ss

Daylight saving time

Addr. 1

Off

Set local time

Next

Prev

3. Controllers

EPOCA

Autoaddress

Com1

On Line

On Line

Off Line

Off Line

Off Line

Off Line

Off Line

Off Line

Off Line

Off Line

Name Name

Name

Addr. 2

Addr. 3

Addr. 4

Addr. 5

Addr. 6

Addr.7

Addr. 8

Addr. 9

Addr. 10

Name

Name

Name

Name

Name

Name

Name

Name

Name

Set the type of IP address and press Next;

7. Press Congure to complete conguration of the device.

7 8

Next

Prev

4. IP Address

EPOCA

IP address:

Dynamic

Next

Prev

EPOCA

Configure

Cod.

Description Cause Effects Resolution

Pr1

Probe error

• Probe not working

• Probe incorrectly

connected

• Incorrect type of

probe

• Code Pr1 displayed

• Alarm output ON

• Compressor regulated

according to C4 and C5

• Defrost suspended

• Check the type of probe

(PO)

• Check probe wiring

• Change type of probe

Pr2

• Code Pr2 displayed

• Alarm output ON

• If P4 = 1, defrost active for time d3

Pr3

• Code Pr3 displayed

• No effect on regulation

rtc

Clock alarm

Clock (RTC) alarm

not working

Clock-connected functions not

present or not synchronised with

the actual time

Set the right time.

If the error persists, replace

the device (RTC battery dead)

AL

Low

temperature

alarm Pb1

Temperature Pb1 >

A1 for a time = A7

• Code AL displayed

• No effect on regulation

Wait until the temperature

read by Pb1 goes below the

alarm threshold (A1-A11)

AH

High

temperature

alarm Pb1

Temperature Pb1 >

A4 for a time = A7

• Code AH displayed

• No effect on regulation

Wait until the temperature

read by Pb1 goes above the

alarm threshold (A4+A11)

id

Door open

alarm

Digital input

activated for a

time > i2

• Code id displayed

• Regulators blocked depending on

the current function in iC1 = 7, 8 or 9

• If i2 = -1 the alarm is

disabled;

• Check i2 and iP1

PF

Power outage

alarm

Power outage for

longer than A10

Code PF is recorded

Check the power supply

wiring

COH

Cond. overheat

signal

Condenser

temperature > C6

• Code COH displayed

• No effect on regulation

Check C6

CSd

High

condensation

alarm

Condenser

temperature > C7

for a time = C8

• Code CSd displayed

• Compressor locked

• Switch the device off then

on again;

• Check C7 and C8

iA

Multi-

purpose

input alarm

Digital input

activated (iC1 = 2)

for a time = i5

• Code iA displayed

• No effect on regulation

Check i5 and i6

CtH

Compressor

thermal

switch alarm

Digital input

activated (iC1 = 5)

The regulator counts the number

of events i8 in the time i7 from

the rst one

• If i7 = 0 alarm is always

automatically reset

• Check i5 and i6

th

Thermal

switch global

alarm

Digital input

activated (iC1 = 5)

The regulator counts the number

of events i8 in the time i7 from

the rst one

• Switch the device off then

on again;

• Check i5 and i6

dFd

Defrost

timeout

alarm

Defrost terminated

due to timeout and

not to reaching

temperature d2

• Code dFd displayed

• No effect on regulation

• Touch any key

• Check d2, d3 and d11

Loading...

Loading...