33

After-Sales Service is at the disposal of the Skilled Technician to provide all necessary information.

POWER CONNECTION

WARNING

• Follow the connection instructions shown in the

“specIFIcatIons and technIcaL data”

paragraph

”

.

• The motor pump power supply must comply with the data indicated on the plate (4): in particular, the power

voltage must not deviate by ± 10 % and the power source must be of a suitable power.

• If the power cable is too short, an extension cable may be used provided it is not longer than 5 m/16 ft and

that the cable section is at least 2.5 mm

2

<AWG 14> (EF 7000 - 12V 4mm

2

<AWG12>).

• Ensure polarity in the connections (see also Figure 5):

red cable

→

positive (+);

black cable

→

negative (-).

• When connecting the motor pump to a battery, proceed as follows:

- if present, disconnect the earth cable;

- connect the red cable to the positive pole (+) of the battery;

- connect the black cable to the negative pole (-) of the battery;

- if present, reconnect the earth cable.

• When disconnecting the motor pump from a battery, proceed as follows:

- if present, disconnect the earth cable;

- disconnect the black cable from the negative pole (-) of the battery

- disconnect the red cable from the positive pole (+) of the battery;

- if present, reconnect the earth cable.

HYDRAULIC CONNECTION

WARNING

• Follow the connection instructions shown in the

“specIFIcatIons and technIcaL data”

paragraph.

• The suction pipes must have a nominal pressure equal to 5 bar (73 psi).

• The delivery pipes must have a nominal pressure not below max. motor pump pressure.

• Do not tighten the suction and delivery ttings to a torque of more than 5 Nm (45 lbf in).

• All the pipes must be rmly fastened with clamps to the respective ttings.

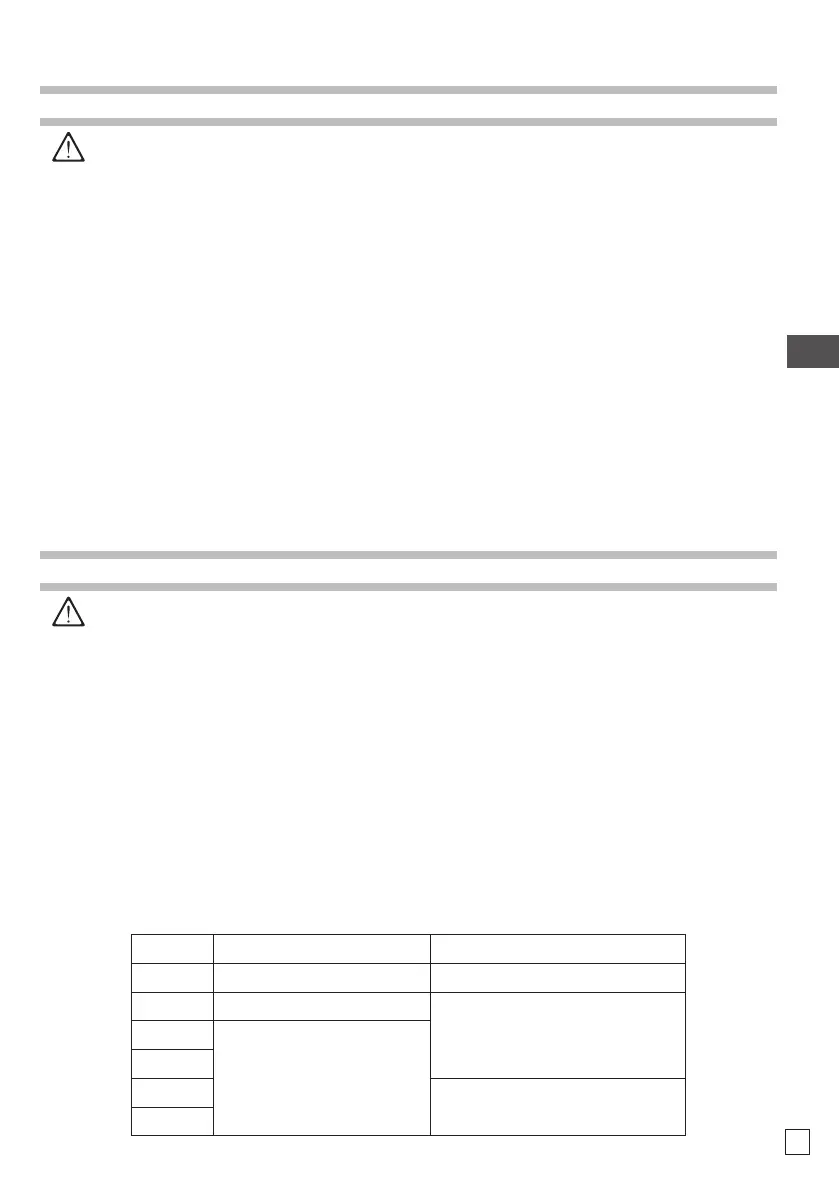

For the hydraulic suction and delivery connections, refer to the following table and to Fig. 6, which

represents a generic diagram of a possible machine in which the motor pump is integrated.

a. Tank

b. Suction lter

c. Suction circuit

d. Motor pump

e. Delivery circuit

f. Spray lance (example of accessory)

The connections to suction and delivery of the motor pump must be done according to the model

considering the couplings and minimum internal pipe diameters illustrated in the following table:

Model Coupling Minimum internal pipe diameter

EF 1200 hose holder Ø 10 mm (3/8") 10 mm (3/8")

EF 2200 3/8 NPT female

13 mm (1/2")EF 3000

1/2 NPT female

EF 4000

EF 5500

19 mm (3/4”)

EF 7000

EN

Loading...

Loading...