Curtiss-Wright | Tritex II DC Rev. J PN49220 2/8/2016

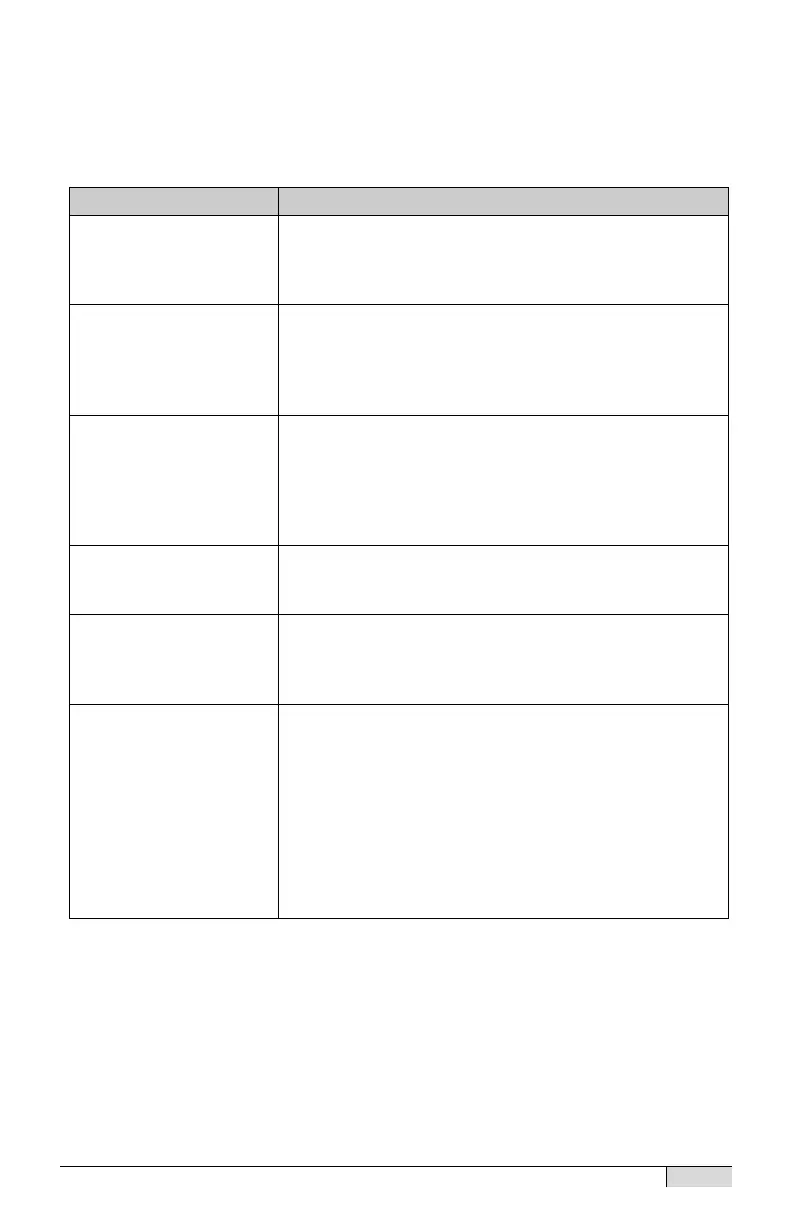

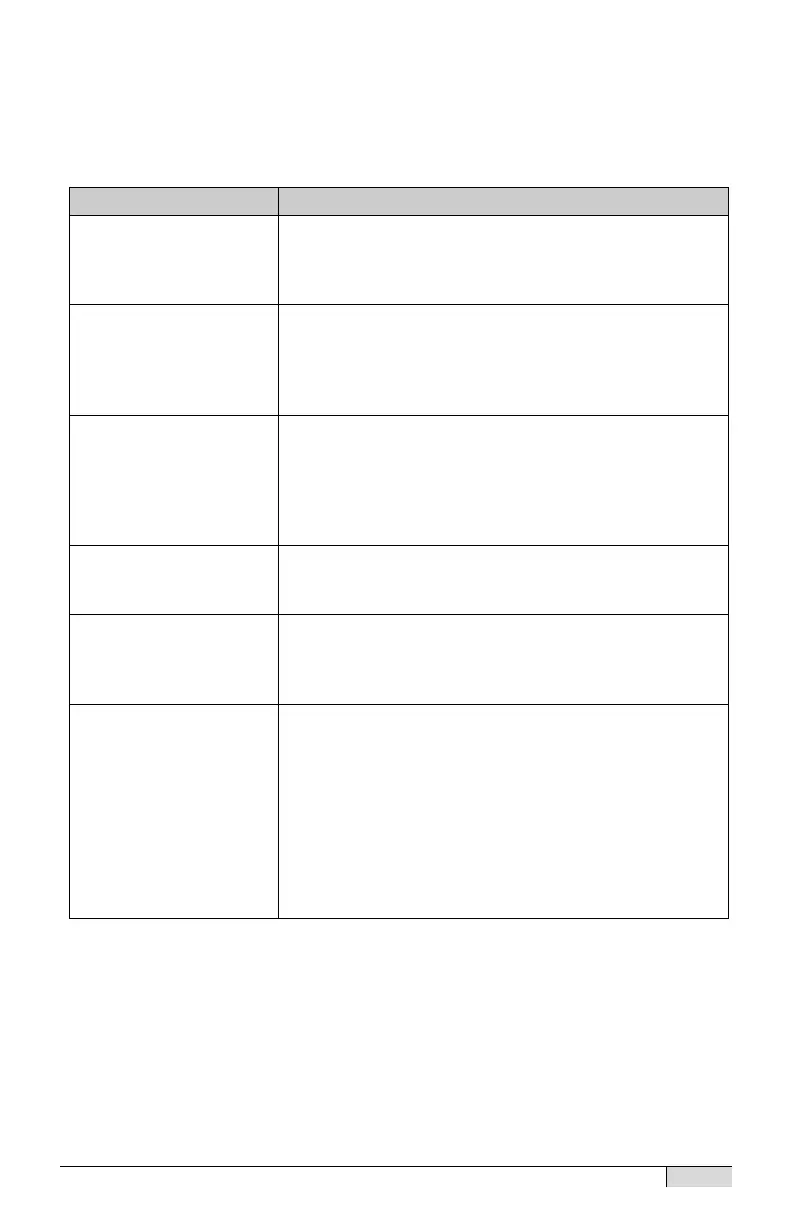

TROUBLESHOOTING PROCEDURES

This section provides you with guidelines and hints on troubleshooting

various problems that may be encountered during installation and

operation of your Tritex Series actuator.

Possible Cause / Troubleshooting Procedure

No response from

actuator.

1. Check drive for faults that may indicate problem via

I/O or Expert software.

2. Check to insure that drive is powered and enabled.

3. Check for proper wiring.

Actuator seems to be

enabled (receiving

current) but is not

operating or is operating

erratically.

1. Drive may be improperly tuned. Check all gain

settings.

2. Check for load irregularities or excess compliance.

Actuator cannot move

load.

1. Load is too large for the capacity of the actuator or

too much friction is present.

2. Excessive side load.

3. Misalignment of output rod to load.

4. Current limit in drive is set too low

5. Power supply has too low of current capacity

Actuator housing moves

or vibrates when shaft is

in motion.

1. Check actuator mounting. Insure that the actuator is

securely mounted.

2. Drive is improperly tuned (wrong gain settings).

Output rod rotates

during motion and thus

does not provide proper

linear motion.

1. Install Exlar anti-rotation assembly or incorporate

anti-rotation into the application.

1. Insufficient cooling for application requirements.

Contact Exlar engineering.

2. Ambient temperature is too high.

3. Actuator is being operated outside of continuous

ratings.

4. Amplifier is poorly tuned causing excessive

unnecessary current to be applied to motor. Check

Gain settings.

5. Over Voltage limit set too low causing internal shunt

control to remain active.

Loading...

Loading...