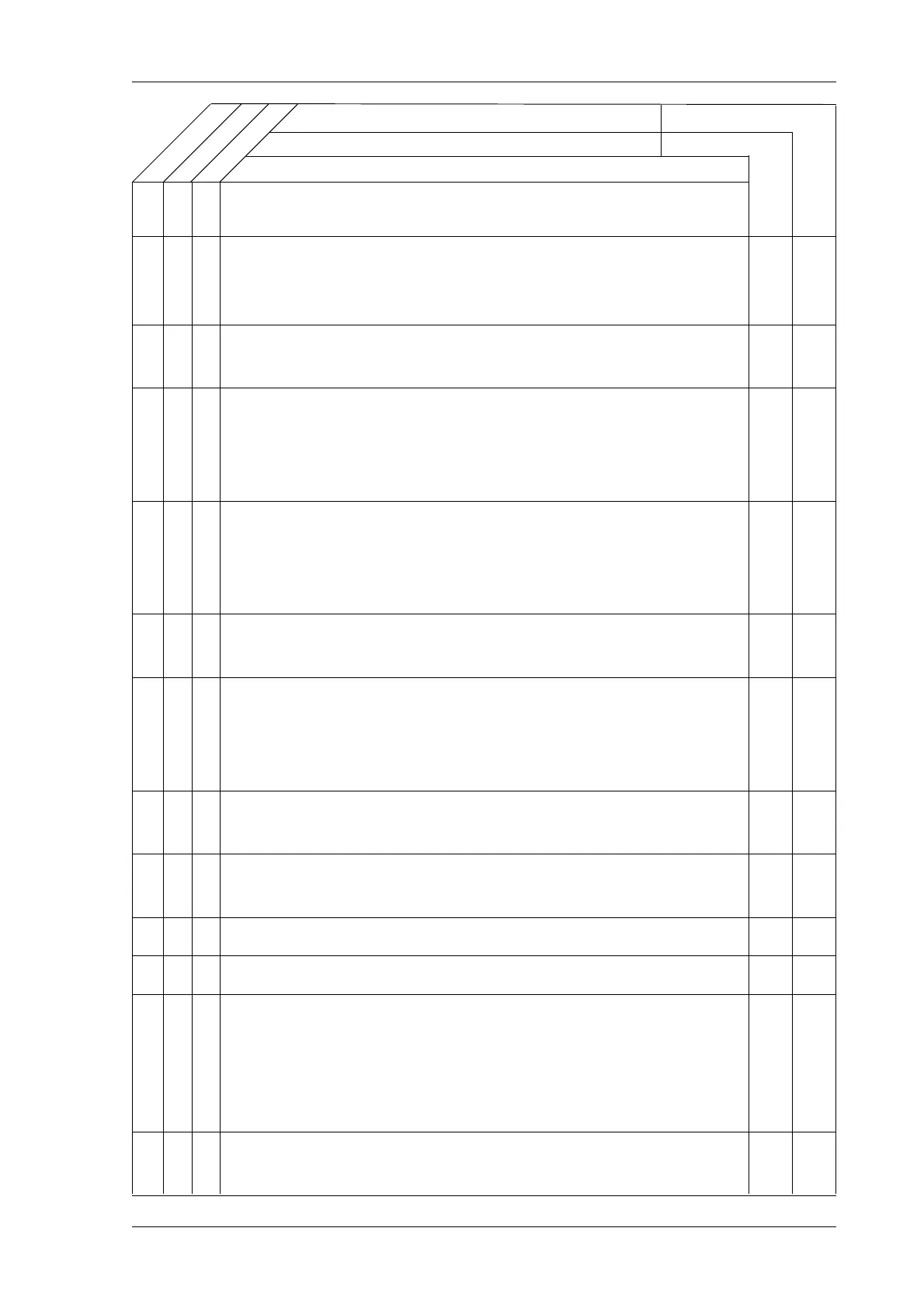

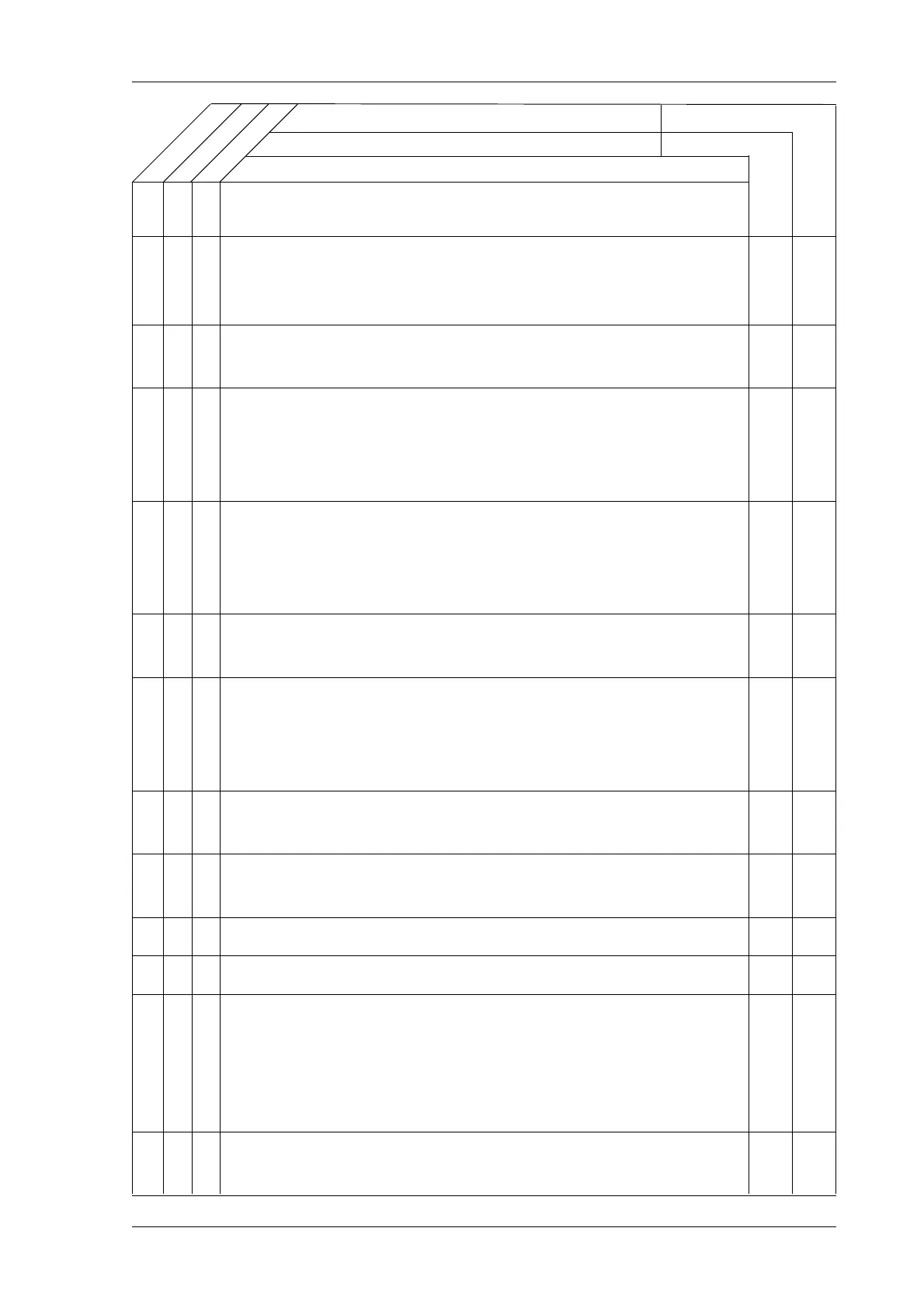

EXT

RA - FLUGZEUGBAU GmbH

SERVICE MANUAL EXTRA 200

CHAPTER 05

PAGE 19

PAGE DATE: 1. July 1996

Wheels

(refer to on-aircraft inspections presented in the latest edition

of Cleveland Wheels & Brakes Maintenance Manual and

Service Bulletins for wheel, tire and break inspections)

O O 1 Visually inspect the wheels for corrosion, cracks, or other

visible damage.

O O 2 Check wheel nuts to be sure they are properly installed and

have not worked loose. Bolt threads should be flush to 1-1/2

threads extending beyond the nut. Nuts should be on the side

of wheel opposite the brake disc (outboard side of wheel).

O O 3 Inspect the brake disc for rust, excessive grooves, large

cracks, coning or other visible damage. Check if disc thick-

ness is more than 0.325in/8.255mm. Coning of disc in excess

of 0.015 in /0.381 mm is cause for replacement (see Fig. 5).

O 4 Remove wheels and wheel bearings. Inspect wheel bearing

grease for contamination and solidification.

O 5 Inspect snap rings and grease seals for distortion or wear.

Replace grease seal felts if they are hard or contaminated.

Lightly saturate grease seals should be replaced if cracked,

dried out, or distorted.

O 6 Inspect wheel bearings for excessive wear or damage. Re-

place on condition.

O 7 Repack bearings with AEROSHELL 22C (per MIL-G-81322),

or equivalent. Reinstall wheels and safety.

O O 8 Check wheel bearing clearance and wheels for free rotation.

Tires

O O 1 Visually inspect tires for cuts, flat sports, and tread or side

wall damage. If changing of tires is necessary follow the

instructions, including off-aircraft inspection of wheels,

presented in the Cleveland Wheels & Brakes Component

Maintenance Manual.

O O 2 Check inflation pressure (2.6 bar /38 psi). Proper inflation

will provide maximum tire and wheel life.

Inspector:

Mechanic:

Date:

Serial No.:

Inspections

as specified

each 50 hours

each 100 hours

SCHEDULED MAINTENANCE CHECKS

Maintenance Checks Schedule

Loading...

Loading...