Page 11

ELECTRIC POWERED PERSONNEL CARRIERS & GOLF CAR

Owner’s Manual and Service Guide

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

lower pressure prevents tires from cutting into the turf.

For vehicles being used on paved or hard surfaces, tire

inflation pressure should be in the higher allowable

range, but under no condition should inflation pressure

be higher than recommended on tire sidewall. All four

tires should have the same pressure for optimum han-

dling characteristics. Be careful not to overinflate. Due to

the low volume of these small tires, overinflation can

occur in a matter of seconds. Be sure to install the valve

dust cap after checking or inflating.

Tire Repair

The vehicle is fitted with low pressure tubeless tires

mounted on one piece rims.

Generally, the most cost effective way to repair a flat tire

resulting from a puncture in the tread portion of the tire is

to use a commercial tire plug.

Tire plug tools and plugs are available at most

automotive parts outlets and have the advan-

tage of not requiring the tire be removed from the wheel.

If the tire is flat, remove the wheel and inflate the tire to

the maximum recommended pressure for the tire.

Immerse the tire in water to locate the leak and mark with

chalk. Insert tire plug in accordance with manufacturer’s

specifications.

If the tire is to be removed or mounted, the tire changing

machine manufacturer’s recommendations must be fol-

lowed in order to minimize the possibility of personal

injury.

To prevent injury, be

sure mounting/demount-

ing machine is anchored

to floor. Wear OSHA approved safety equipment when

mounting/demounting tires.

Follow all instructions and safety warnings provided by

the mounting/demounting machine manufacturer.

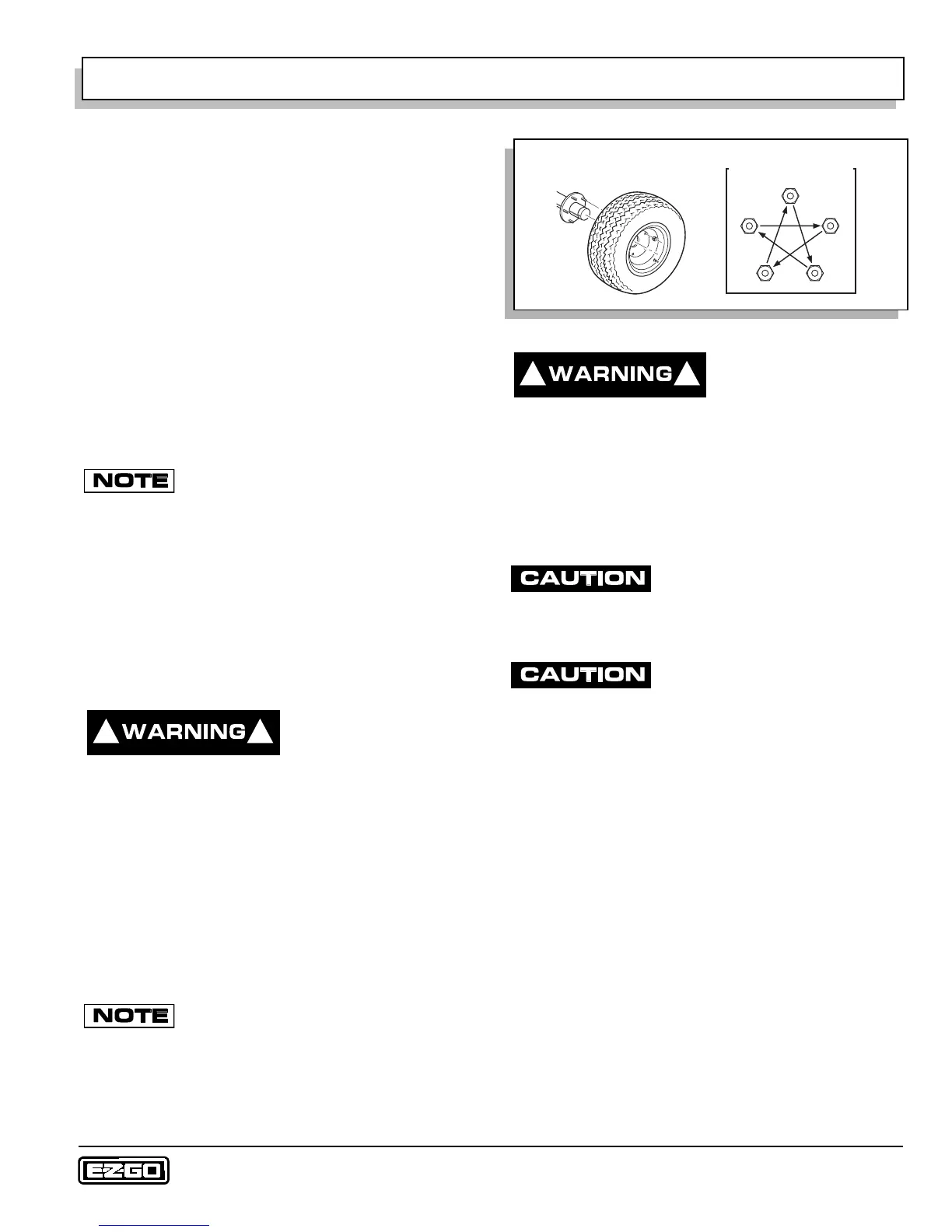

Wheel Installation

With the valve stem to the outside, mount the wheel onto

the hub with lug nuts. Finger tighten lug nuts in a ‘cross

sequence’ pattern (Ref Fig. 14 on page 11). Then, tighten

lug nuts to 50 - 85 ft. lbs. (70 - 115 Nm) torque in 20 ft.

lbs. (30 Nm) increments following the same ‘cross

sequence’ pattern.

It is important to follow the ‘cross sequence’

pattern when installing lug nuts. This will

assure even seating of the wheel against the hub.

To prevent injury caused

by a broken socket, use

only sockets designed

for impact wrench use.

Tire condition should be inspected on a daily basis. Infla-

tion pressures should be checked on a weekly basis

when the tires are cool. When removing wheels with an

impact wrench, use only impact sockets. Regular sock-

ets are not designed for impact pressures exerted by

power tools.

Do not tighten lug nuts to more than 85

ft. lbs. (115 Nm) torque.

LIGHT BULB REPLACEMENT

To prevent premature bulb failure, do

not touch new bulbs with bare fingers.

Use a clean, dry tissue or paper towel to handle the glass portion

of the bulb

.

Always hold bulbs with a clean, dry tissue or paper towel.

Natural oils from fingers will cause halogen bulbs to fail

prematurely.

Determine which bulb needs to be replaced. Reach

underneath light bar to access bulb from rear. Turn the

bulb socket a quarter turn counterclockwise to unlock

and pull out bulb. Insert new bulb and rotate quarter turn

clockwise to secure.

To replace the taillight bulb, remove hardware securing

lens and remove lens. Install replacement bulb and rein-

stall lens.

! !

Fig. 14 Wheel Installation

Tire/wheel style

may vary

'Cross Sequence'

1

25

3

4

! !

Loading...

Loading...