8

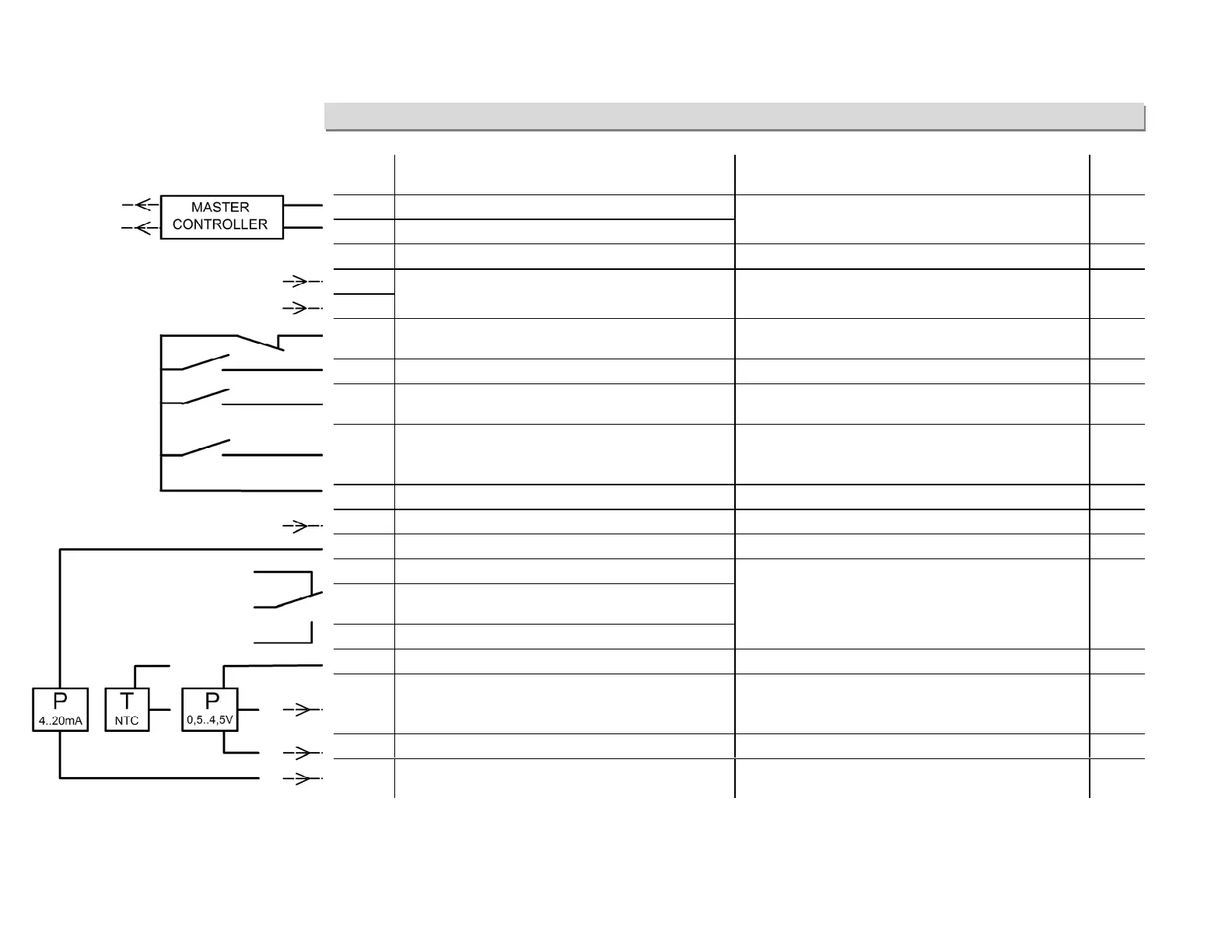

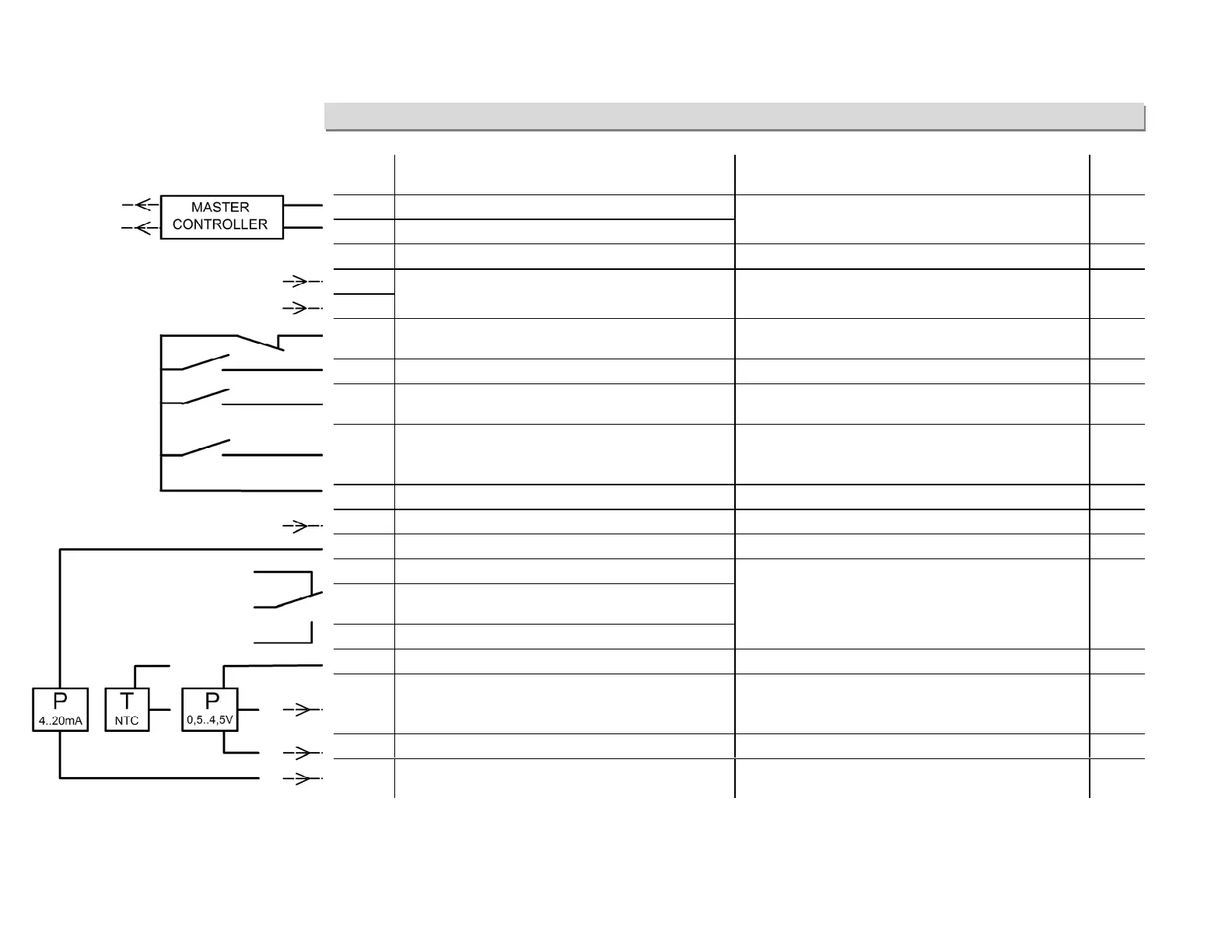

CONTROLS TERMINAL BOARD

Term.

Description Application Page

T1+ Serial RS485, Modbus RTU - Slave

T1 - Serial RS485, Modbus RTU - Slave

Serial connection line to a Master controlled device

25

0V Ground I/O Mass I/O

IF

IF

Pwm FV, 2..20kHz input (Ri =500Ω, 5..24V)) Variable frequency command for mode slave

running

22

I 4 External emergency input Open immediately blocks the control. It can be

connected to the load temp. protecting device/s

I 3 Start/Stop input Programmable Start/Stop input 23

I 2 Limit Speed function input Closed modifies the adjusting modes. It is often

used for the night silenced operating

20

I 1 Direct/Reverse function input Open enables the Cool1 cooling mode. Closed

enables the Heat or Cool2 heating mode (to be set

on basic sett. menu)

22

0V Ground I/O Mass for the digital inputs

0.10 Analog input , type 0.10V (Ri = 40k Ω) 0..10V command for mode slave running 22

+V 12V power supply output = (max 30mA) 4..20mA pressure transducer power supply

NC Relay 1 closed norm. contact output

COM Relay 1 common contact output

(1A-250V~/3A-30V=)

NO Relay 1 open norm. contact output

Programmable output. With standard setting for

Defect, the relay is enabled (NO-COM eachother

closed) and is disabled by turning to the position

represented in the picture in emergency case.

24

+5V 5V power supply output = (max 15mA) Ratiometric press. transd. and NTC power supply

IN 1 Analogical input 1, type 0,5…4,5V / ntc

(10 kΩ @25°C, β3435), (Ri = 10 kΩ) / pwm 5..15V

Ratiometric pressure transducers / NTC sensor /

Pwm 100Hz type with variable average value

21-22

0V Ground I/O Mass for analogical input

4.20 Analogical input 1, type 4…20mA (Ri = 100 Ω) 4..20mA pressure transducers input,command for

mode slave running

21-21

Loading...

Loading...