UNLESS OTHERWISE STATED, PAR

NOT TO BE ADJUSTED BY THE

Please ensure that any plastic coatings

to use. Before operation, pan requires

cleaned and dried.

Discolouration of heated parts is

testing to ensure a satisfactory unit.

quality or performance.

1.1 MODEL NUMBERS, NETT

and DIMENSIONS

Model

Width

(mm)

Depth

(mm)

G401F Fryer

400

840

G402F Fryer

400

840

Pan oil capacity:

18 litres cold, good quality oil (to -

1.2 SITING

The unit must be installed on a firm,

lit draught free position. The fryer

in a position where the possibility of

likely when force is applied. The

be the manner of installation, such

a battery of appliances or installing the

or by separate means, such

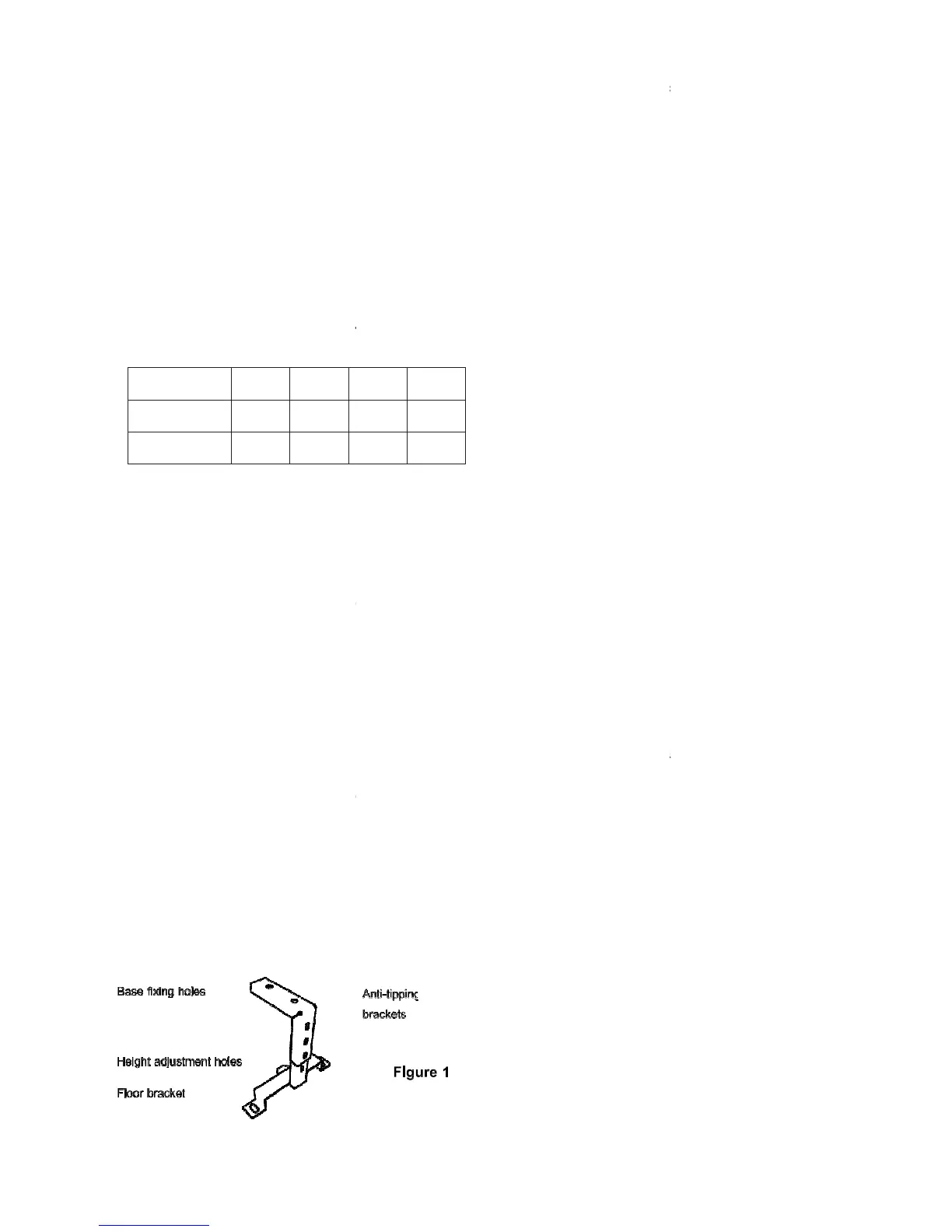

1.2.1 Anti-tipping Accessory

An anti-tipping mechanism is also

accessory. If these are to be fitted, the

fitted to locate the fryer in the correct

any walls as detailed below. Fixing

the fryer base to accommodate the

should be fitted as detailed in Figure

chain has a quick release eyelet.

and secure bracket to floor after

anti-tipping device attached to the

below floor bracket.

Figure 1 - Anti-tipping

Height

(mm)

Weight

(kg)

1200

94

1200

94

1.2.2 Clearances

The unit requires a

Important

If fryer is to be installed

wall or overlying surface.

Some appliances require

determine overall distance

adjoining appliances.

1.3 VENTILATION

The appliance ventilation

should be installed under a

harmful to health.

For multiple installations,

together. Installations should

A competent engineer must

work.

1.4 GAS SUPPLY (Both

The SIT gas valve, situated

governor. The inlet pressure

should be set at test nipple

Page 4 (for either natural

of at least 150mm to rear

other appliances then the

vertically from top of unit.

or outside air. The fryer

natural or mechanical must

be made in accordance with

be used for any installation

gas conversion or repair.

at rear RH side of unit and

should be checked at valve

Loading...

Loading...