Model 35 Viscometer Instruction Manual

208878 Revision N, February 2013 29

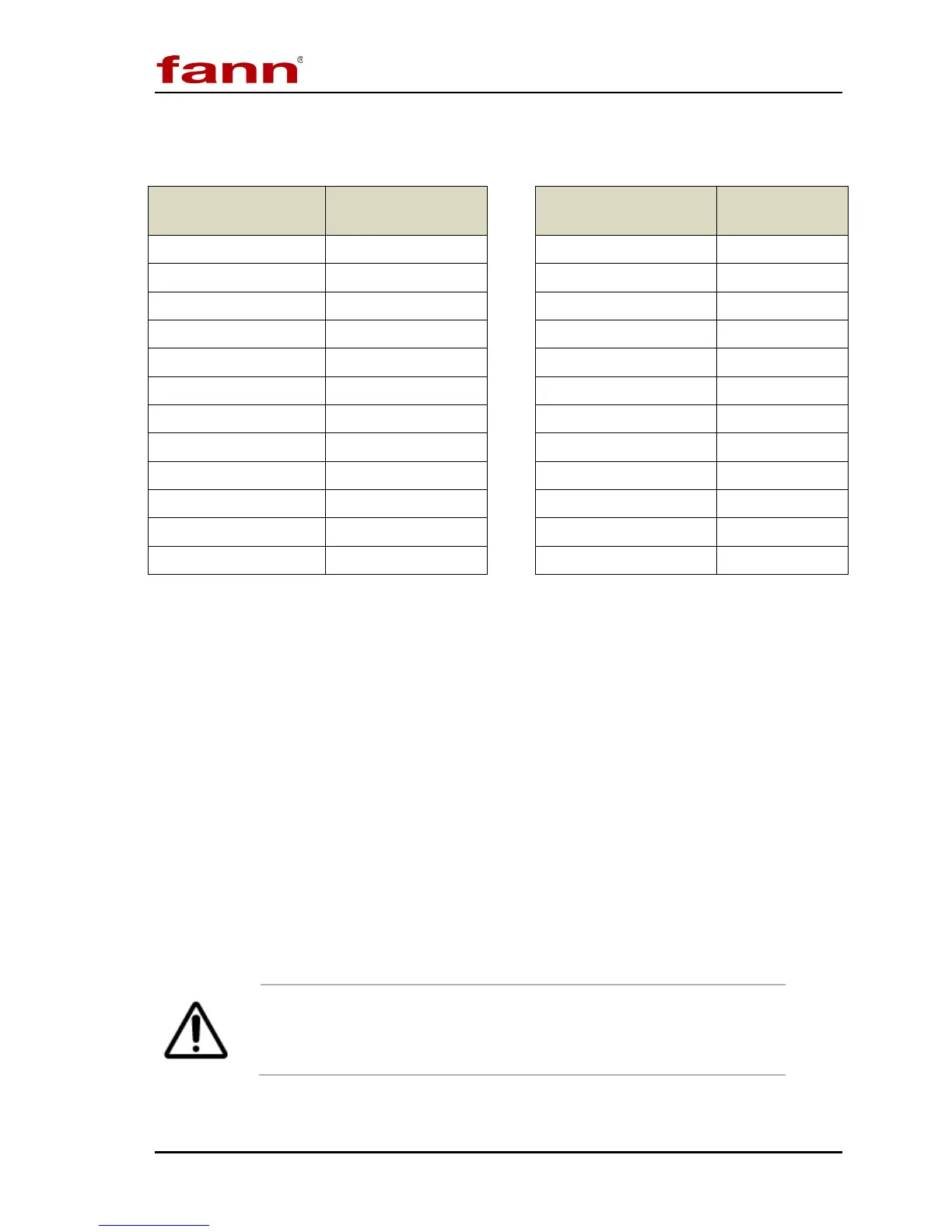

Table 7-1 Rotor-Bob Factor (C)

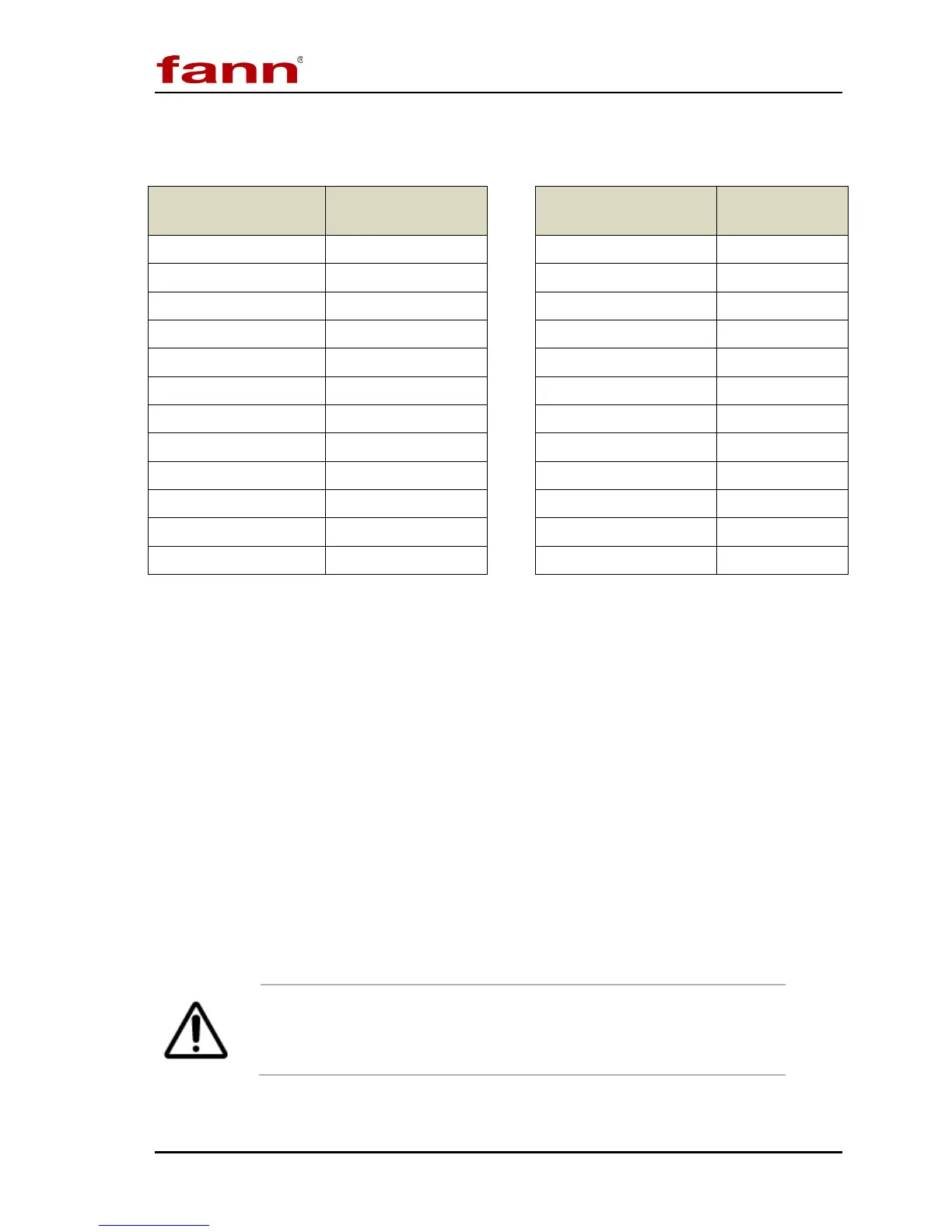

Table 7-2 Speed Factor (S)

Rotor-Bob

Combination

R-B Factor

(C)

Rotor

(rpm)

Speed Factor

(S)

R1-B1 1.000 0.9 333.3

R1-B2 8.915 1.8 166.6

R1-B3 25.392 3 100

R1-B4 50.787 6 50

R2-B1 0.315 30 10

R2-B2 8.229 60 5

R2-B3 24.707 90 3.33

R2-B4 49.412 100 3

R3-B1 4.517 180 1.667

R3-B2 12.431 200 1.5

R3-B3 28.909 300 1.0

R3-B4 57.815 600 0.5

7.2 Plastic Viscosity and Yield Point Calculation

Using R1-B1-F1 combination, test a sample at 600 rpm and record the dial reading.

Change the speed to 300 rpm and record the dial reading.

Determine the plastic viscosity (PV) and yield point (YP) using the following

equations. PV represents the slope of a straight line between the two dial readings.

YP represents the theoretical point at which the straight line, when projected, will

intercept the vertical axis.

PV (cP) = θ

600

– θ

300

Equation 7-2

YP (lb/100 ft

2

) = θ

300

– PV Equation 7-3

where θ is the dial reading

A spring other than F1 may be used if the dial readings are

multiplied by the proper “f” factor, but the other rotor-bob

combinations cannot be used for this two-point method.

Loading...

Loading...