Model 35 Viscometer Instruction Manual

208878 Revision N, February 2013 32

η =

Equation 7-7

where

is the shear stress, dynes/cm

2

is also calculated as k

1

k

2

θ

γ is the shear rate, sec

-1

γ is also calculated as k

3

N

η is the viscosity, Poise

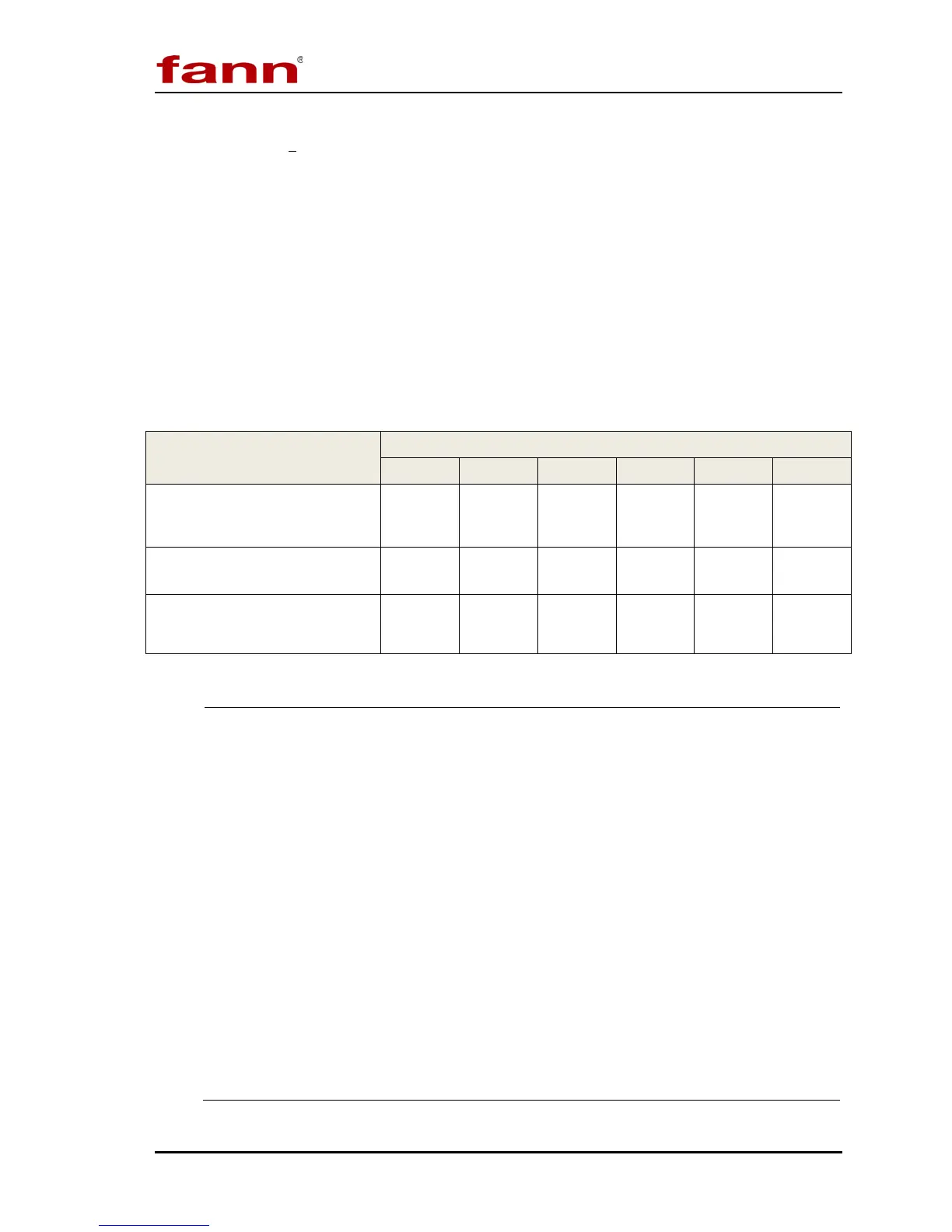

Table 7-4 Constants for Viscosity Calculations

Constant

Rotor-Bob Combinations

R1 B1 R2 B1 R3 B1 R1 B2 R1 B3 R1 B4

Overall Instrument Constant, K

Standard F1 Torsion Spring

η = Kfθ/N

300 94.18 1355 2672 7620 15,200

Shear Rate Constant k

3

,

(sec

-1

per rpm)

1.7023 5.4225 0.377 0.377 0.268 0.268

Shear Stress Constant for

Effective Bob Surface k

2

,

-3

0.01323 0.01323 0.01323 0.0261 0.0529 0.106

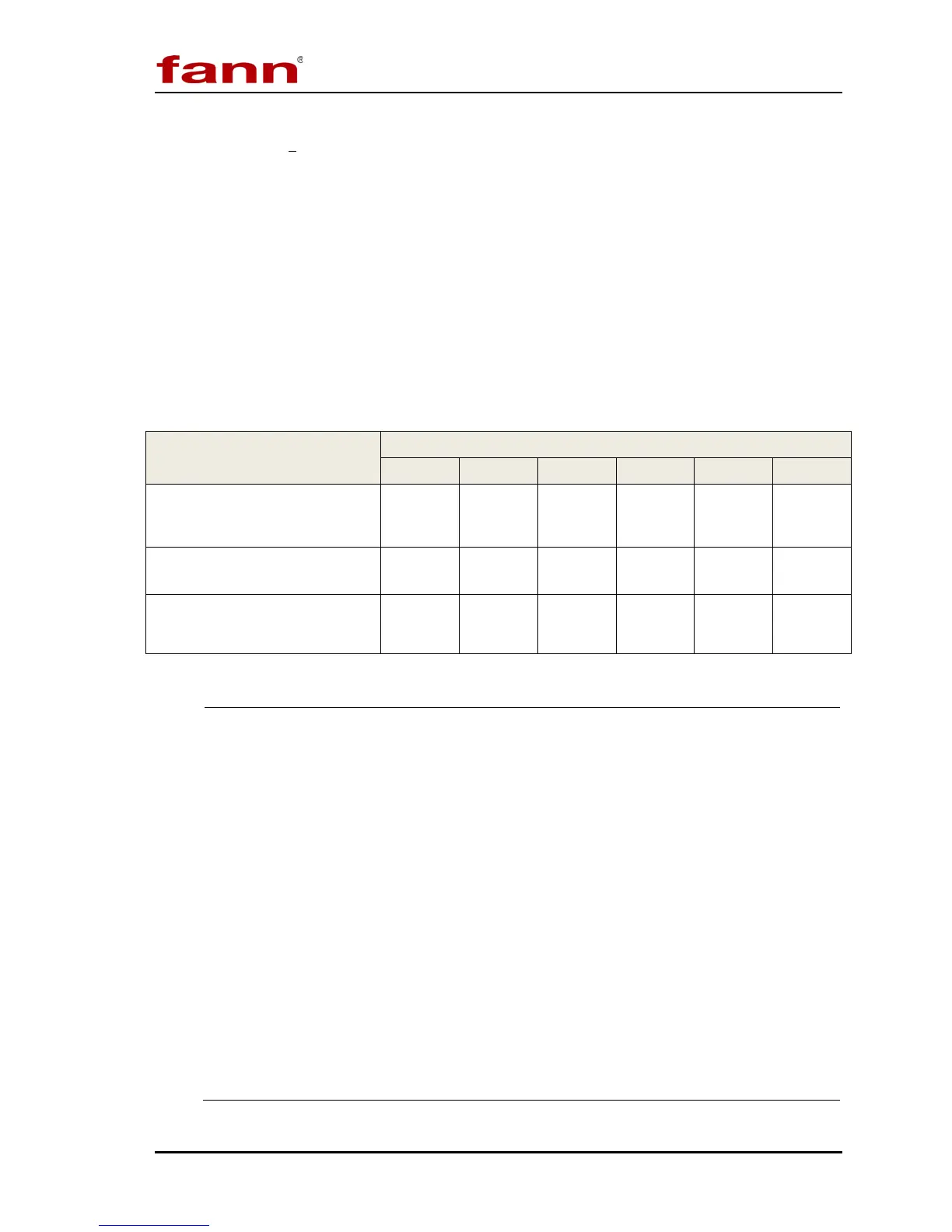

Table 7-5 Conversion Factors

Symbol Unit Conversion Factor

SI Units

Shear Stress

τ

Pa

(Newton/m

2

)

1 Pa = 10 dynes/cm

2

Shear Rate

γ

s

-1

1 s

-1

(no change)

Viscosity ƞ

Pa ⋅ s

mPa⋅ s

1 Pa ⋅ s = 10 poise

1 mPa⋅ s = 1 cP

Oilfield Units (R1-B1-F1)

Shear Stress

τ

dynes/cm

2

1

•

Fann = 5.11 dynes/cm

2

Shear Stress

τ

lb/100 ft

2

1

•

Fann = 1.065 lb/100 ft

2

Shear Stress

τ

lb/100 ft

2

1

•

Fann = 1 lb/100 ft

2

Shear Rate

γ

1/sec 1/sec = 1.7023 N

Viscosity

µ cP

µ = (5.11θ / 1.70N) x 100= 300 x (θ / N)

Effective Viscosity

µ

e

cP

µ

e

= 300 x (θ / N)

Loading...

Loading...