Model 35 Viscometer Instruction Manual

208878 Revision N, February 2013 30

7.3 Spring Constant Calculation

This calculation applies to the dead weight calibration method.

Equation 7-4

where

K

s

is the spring constant in dyne-cm/degree deflection

G is the load in grams

g is the gravitational constant at 981cm/sec

2

r is the radius arm at 1cm

θ is the dial reading in degrees

Example: The required setting for the F1 spring is 386 dynes/cm/degree

deflection with the R1-B1 combination. Using the 50 gram weight supplied with

the calibration kit, the spring constant is

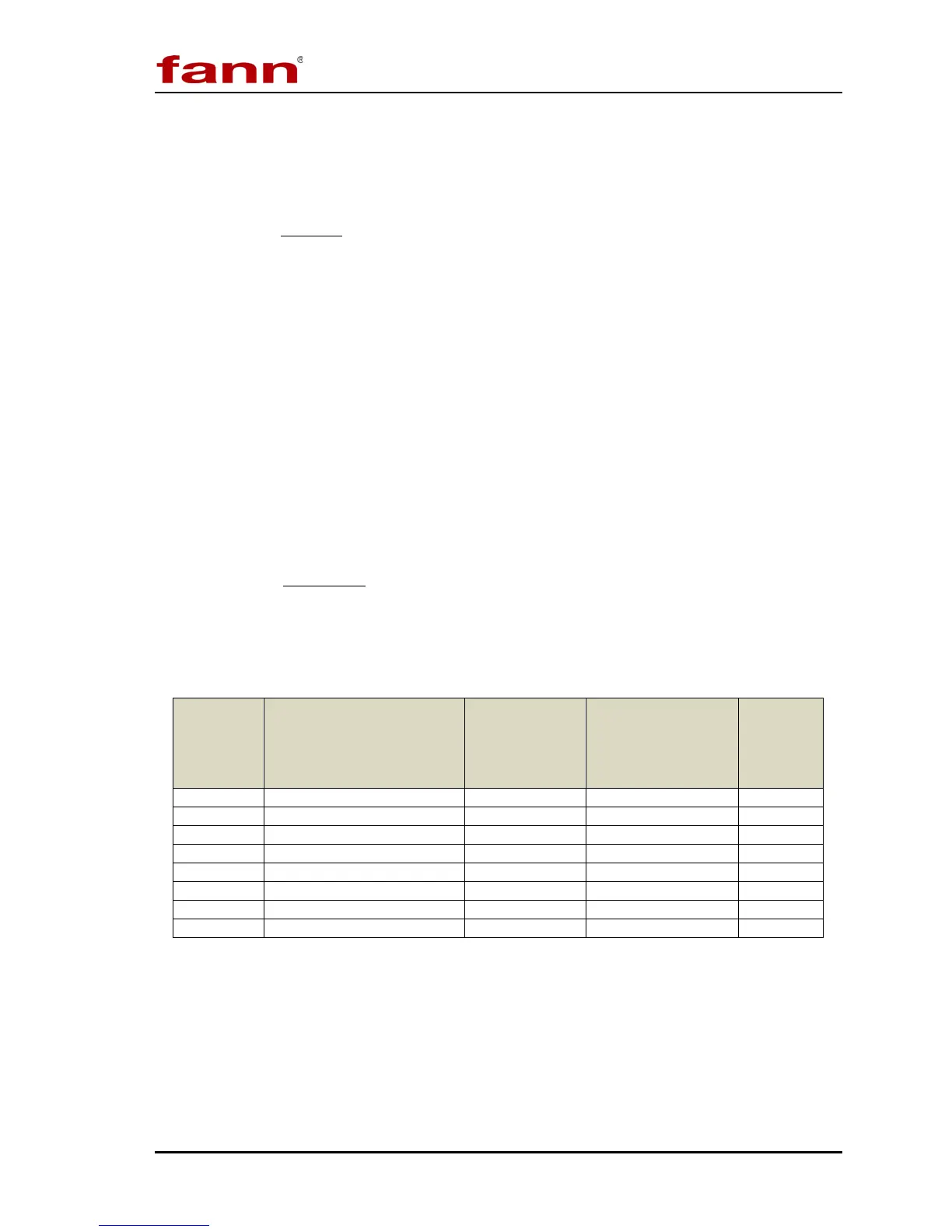

Table 7-3 Torsion Spring Specifications

Torsion

Spring

Assembly

Constant*

k

1

(dyne/cm/degree

Torsion

Spring Factor

f

Maximum Shear

Stress with B1

Bob

(dyne/cm

2

)

Color

Code

*With R1-B1 Combination

Loading...

Loading...