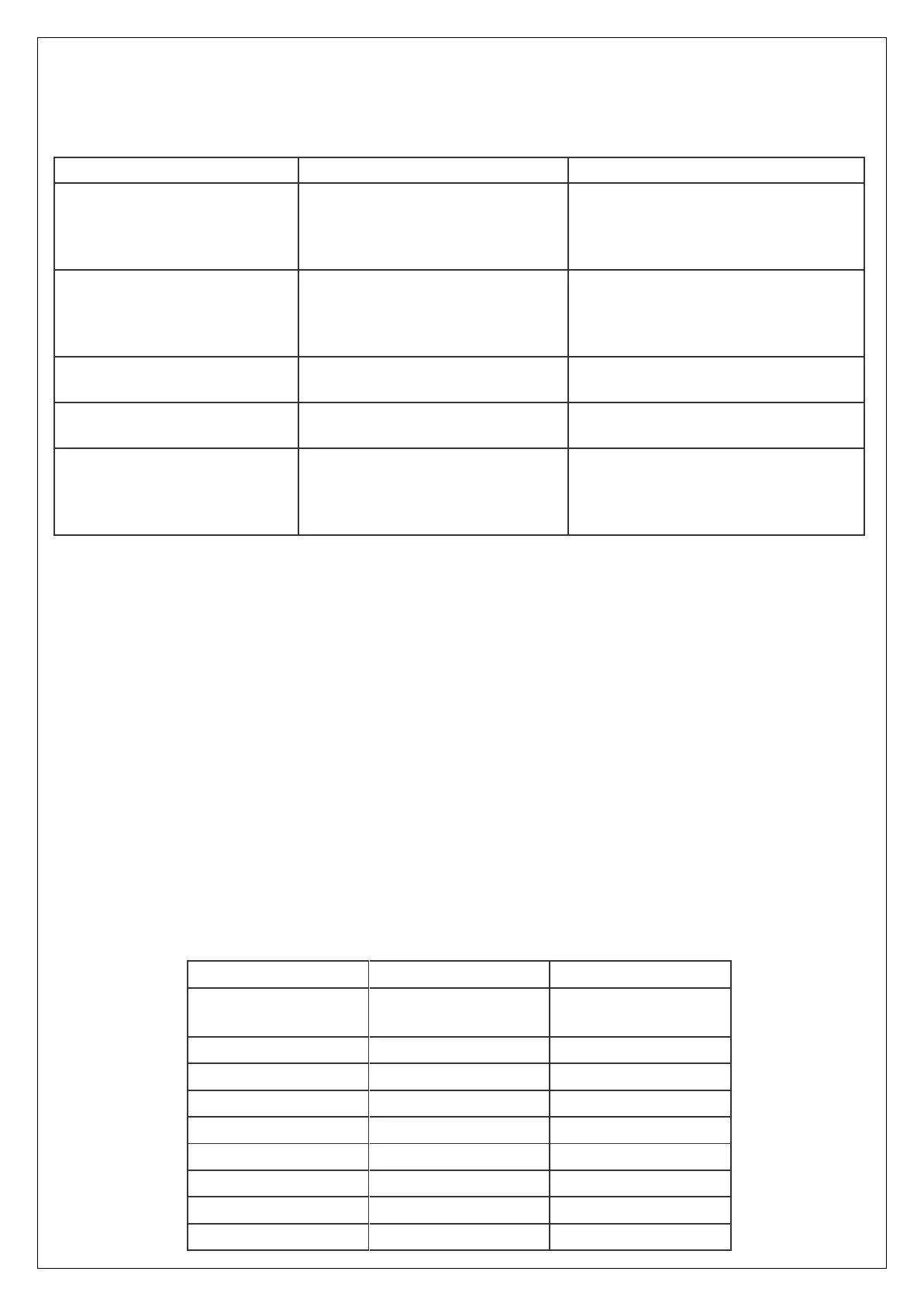

9. TROUBLESHOOTING

Oil leaking from gearbox/

transmission case

• Gearbox overfilled

•

Loose filling/drain/level plug

•

Damaged breather plug

•

Damaged seals

• Drain to proper level

•

Replace breather plug

•

Tighten filling/drain/level plug

•

Replace seals

• Worn blades/hammers

•

Roller/wheels set in wrong

way

•

Debris wrapped on rotor

•

• Dirty shredding room

• Replace blades/hammers

•

Set the roller/wheels correctly

•

Reduce the ground speed

•

Clean the shredding room

• Low oil level

•

Materiale di diffi cile

trinciatura

• Add oil

•

Reduce the ground speed

Blades/hammers wear

frequently

• Hard trash

•

Cutting height too low

• Check the soil in advance

•

Increase the cutting height

Flail Mower noise and

vibration noticeable and

constant

• Unbalanced roller

•

Worn bearings

• Blades/hammers worn,

damaged or missing

• Balance the roller in authorized

•

shop

•

Replace bearings

•

Replace blades/hammers

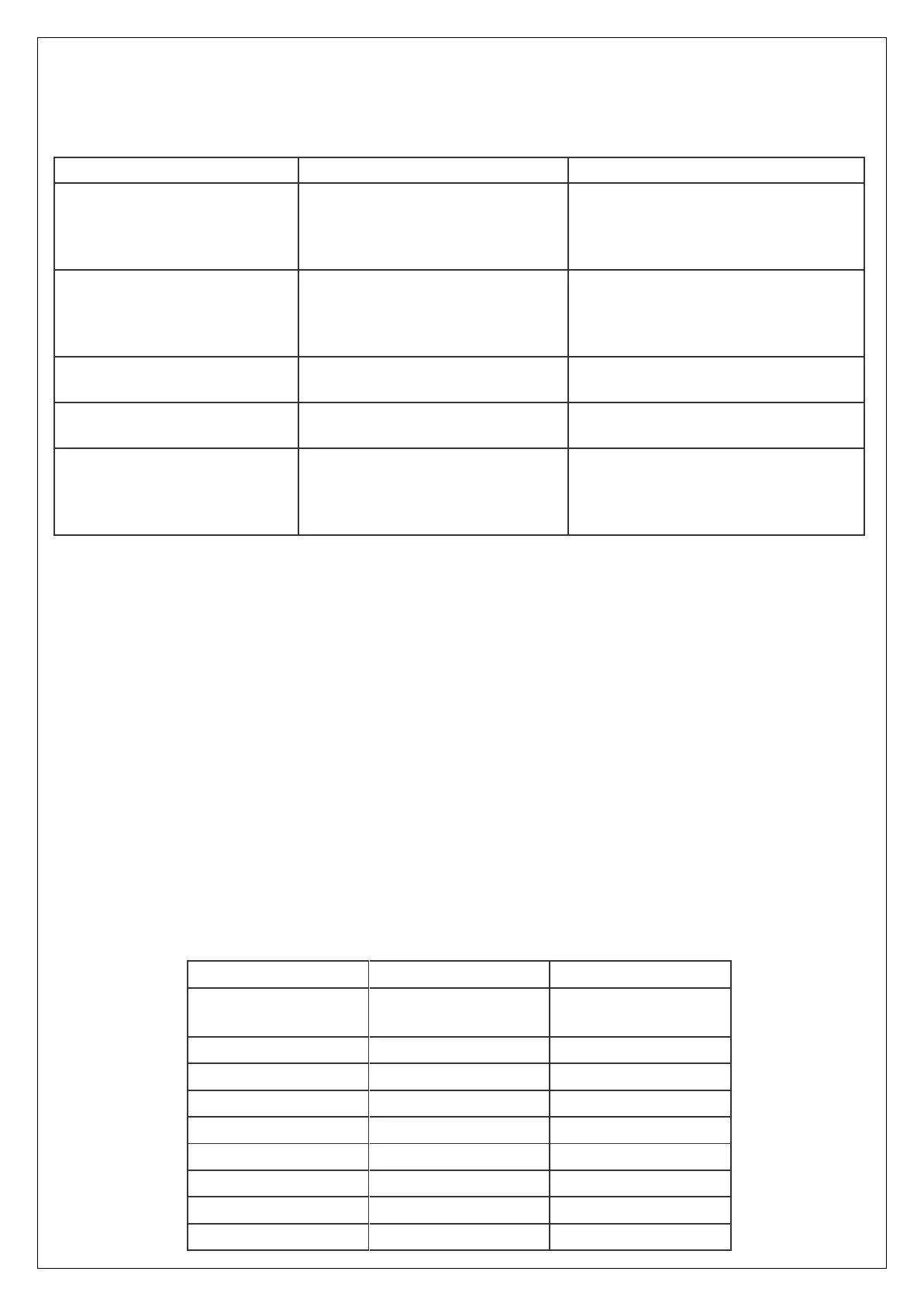

10. TORQUE

VALUES TABLE

Check

frequently

Flail Mower

hardware to

make sure

that screws

and bolts are

tightened

according to

torque

values listed

in following

table:

11.

SPAR

E

PART

S

All

repairs

and

replace

ments

on the

machin

e must

be

perfor

med

only by

using

origina

l spare

parts,

which

must

be

obtain

ed

from

the

Manuf

acturer

or your

Dealer.

This section contains the information needed to

identify the parts of FLAIL MOWER that may be

ordered to

M

a

n

u

f

a

c

t

u

r

e

r

.

When request spare

parts to

Manufacturer, always

give following

indications:

•

t

y

p

e

o

f

m

a

c

Loading...

Loading...