2

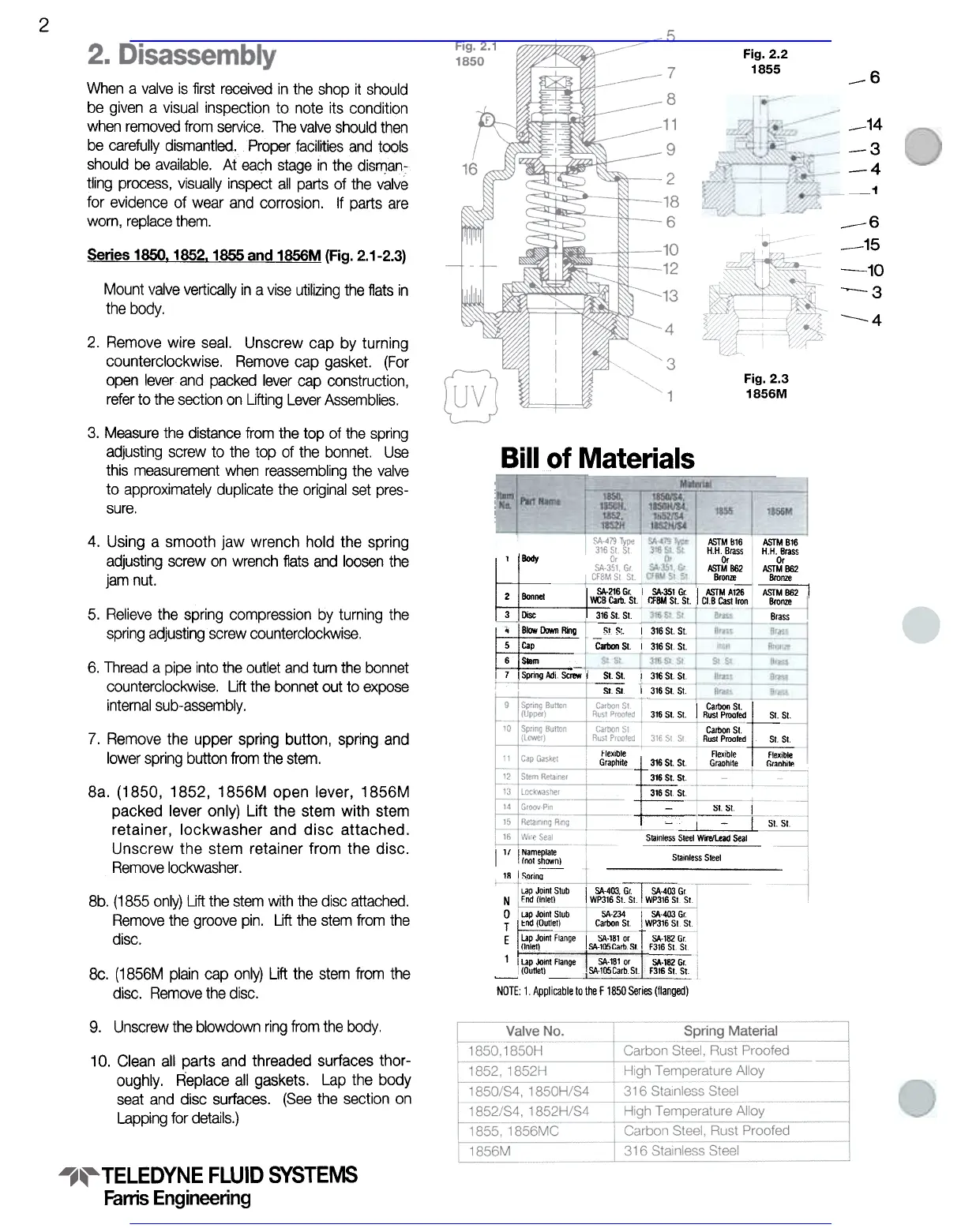

Fig. 2.2

1855

_6

c--14

-3

-4_1

_6

_15

-10

-3---4

Series 1850. 1852.1855 and 1856M (Fig. 2.1-2.3)

Mount valve vertically in a vise utilizing the flats in

the body.

2. Remove wire seal. Unscrew cap by turning

counterclockwise. Remove cap gasket. (For

open lever and packed lever cap construction,

refer to the section on Lifting Lever Assemblies.

Fig. 2.3

1856M

3. Measure the distance from the top of the spring

adjusting screw to the top of the bonnet. Use

this measurement when reassembling the valve

to approximately duplicate the original set pres-

sure.

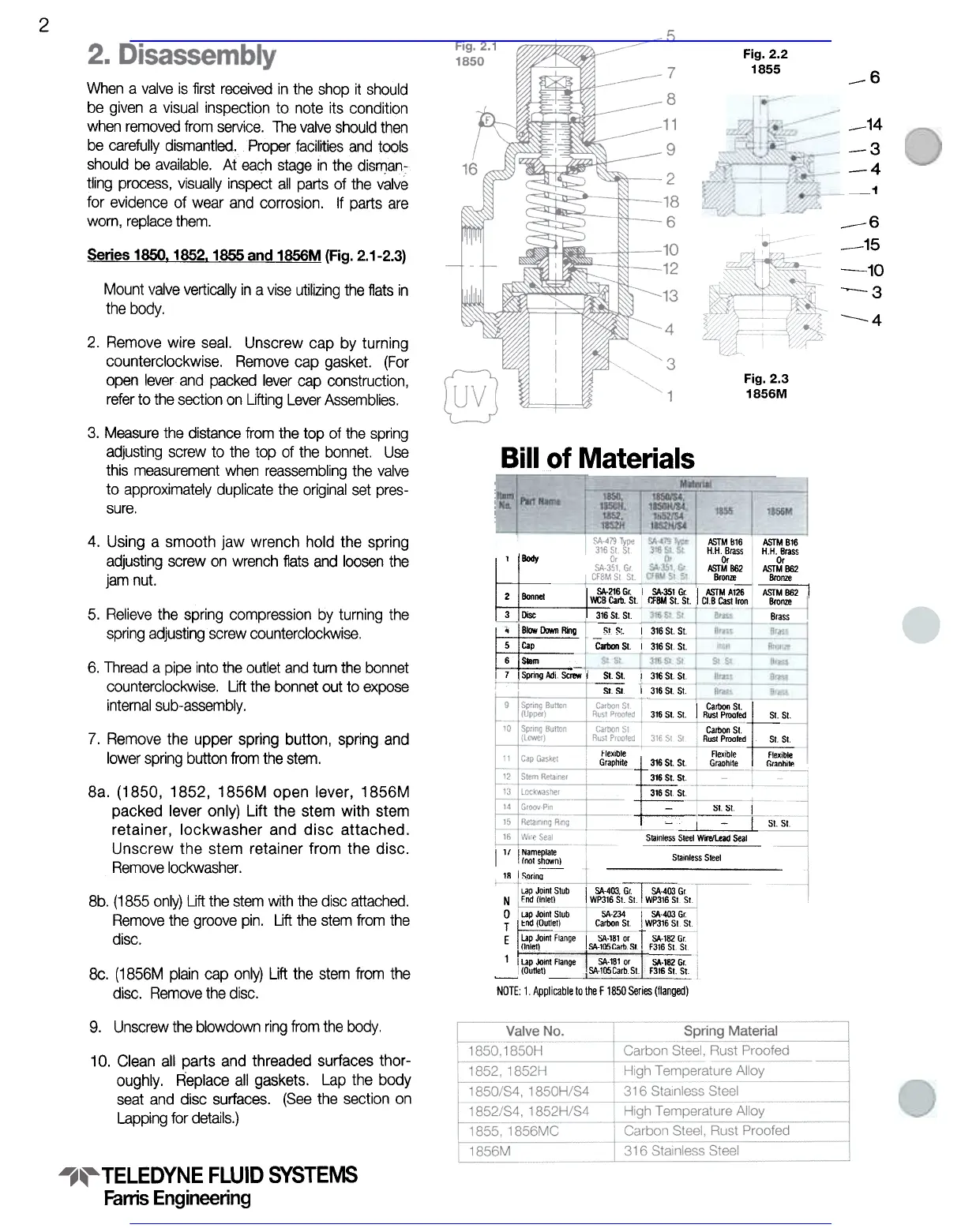

Bill of Materials

4. Using a smooth jaw wrench hold the spring

adjusting screw on wrench flats and loosen the

jam nut.

SA-4791Ype

31681 81.

Or

SA-3S1. Gr

Cf8M 51. 51.

ASTM 816

HH 8rass~

Body Or ASTM B62 Bronze

SA-216 G( I SA-351 G( ~MA126

2 Bonnet Y«:B Carb. 51 CFBM 51. 51 I CIS Cast Iron

3 Disc 316 51 51

51. 51

ASTM B16

HH. Brass

Or

ASTMB62

Bronze

ASJM 862 ,

Bronze

5. Relieve the spring compression by turning the

spring adjusting screw counterclockwise.

316 5t 51

Brass

Brass

Iron

St St

Brass

Brass

Brass

:. I 316 St St

-~~~!

316StSt

Blass

Bronze

Brass

Brass

Brass

~ BIow riI7N!, Ring

5 Cap

6s.m

! 316 51 51

6. Thread a pipe into the outlet and turn the bonnet

counterclockwise. Uft the bonnet out to expose

internal sub-assembly.

I 7 ISpringAdj Screw i ~

St. St

131651 51

~

I 31651. 51.

I Carbon 51.

f:g316 51. 51. AuSI Proofed 51. 51. Carbon 51.

Ausr PrOOled 51. 51

Flexible

GraDhile

7. Remove the upper spring button, spring and

lower spring button from the stem.

Flexible

Graphite

Flexible

Graphite

316 51. 51

31651.51

31651 51

;;;

8a. (1850, 1852, 1856M open lever, 1856M

packed lever only) Lift the stem with stem

retainer, lockwasher and disc attached.

Unscrew the stem retainer from the disc.

Remove lockwasher.

51 51

1 17 INameplate

(not shfNIn)

18 I SDrin-;;-

-~ I

I -I

Stainless 51..1 WOe/lead Seal

Stainless Sleel

Lap Joint Stub

I $A-403, G;T":SA:403 Gr.

End ilnlet) WP316 SI-St I WP316 St SI

8b. (1855 only) Lift the stem with the disc attached.

Remove the groove pin. Lift the stem from the

disc.

SA-234 I SA 403 Gr.

Carbon SI. WP316 SI. SI.

N

0 ! Lap Joint Stub

T

~nd (Outlet)

E Lap Joint flange I SA-181 or T SA-182 Gr

(Inlet) SA-105CarbSt f316 St St

1

IUPJointflange ~

~ (Outletl F316 S~

NOTE: 1 Applicable to the F 1850 Series (lianged)

SA.181 or

ISA.105CarbSt

Sc. (1856M plain cap only) Lift the stem from the

disc. Remove the disc.

9. Unscrew the blowdown ring from the body.

10. Clean all parts and threaded surfaces thor-

oughly. Replace all gaskets. Lap the body

seat and disc surfaces. (See the section on

Lapping for details.)

TELEDYNE FLUID SYSTEMS

Farris Engineering

When a valve is first received in the shop it should

be given a visual inspection to note its condition

when removed from service. The valve should then

be carefully dismantled. Proper facilities and tools

should be available. At each stage In the dismao-:

tling process, visually inspect all parts of the valve

for evidence of wear and corrosion. If parts are

worn, replace them.

Visit www.boighill.com to request a quote.

Visit www.boighill.com to request a quote.

Loading...

Loading...