7

WATER -Before starting the seat tightness test, the outlet

body bowl shall be filled with water, and the valve shall be

allowed to stabilize with no visible flow from the valve outlet.

The valve shall be observed for "1 minute at the test pressure.

There shall be NO VISIBLE LEAKAGE at the valve outlet.

Soft Seated Valves

Soft seated valves shall be tested at 95% of set pressure

when set above 100 psig; they shall be tested at 5 psig

below set pressure when the set pressure is less than or

equal to 100 psig.

8l8: There shall be NO LEAKAGE (ZERO BUBBLES) using

the test method outlined above.

STEAMgng WATER: There shall be NO VISIBLE LEAKAGE

at the valve outlet.

2. If any valve fails to meet leakage requirements it shall be

reworked.

3. Assemble appropriate CAP CONSTRUCTION after leak

tightness has been verified. If valve type is OPEN LEVER,

no back pressure test is required. PLAIN CAP and

PACKED LEVER valves must be back pressure tested as

outlined in the next section.

BACK PRESSURE TEST

1. This test applies to all valves designed for discharge to a

closed system (PLAIN or PACKED LEVER CAP CON-

STRUCTION) with inlet sizes larger than 1" NPS.

2. The secondary pressure zone of the valve shall be tested

with air or other suitable gas at a pressure of at least 30

psi. The valve should be pressurized at the outlet with

shop air or other means. A soap solution or other suitable

solution shall be applied to all connections which are

potential leakage paths (i.e., body/bonnet connection,

cap/bonnet connection, packed lever assembly/cap con-

nection). No leakage is acceptable.

3. If leakage is detected at any location the valve shall be

reworked.

~~ TELEDYNE FLUID SYSTEMS

FarTis Engineering

TESTING AND SETTING PROCEDURE:

1. Mount the valve on the test stand. Use air as the test

medium for air, gas and vapor or flashing service appli-

cations. Set valves for saturated steam service on satu-

rated steam. Valves for steam service set with air

should include temperature compensation. The name-

plate provides "Cold Differential Set Pressure." Set

valves for liquid service on water.

2. Hold the STEM tightly and tighten (turn clockwise) the

SPRING ADJUSTING SCREW to increase the spring

force. Make sure the stem does not rotate while load-

ing the SPRING.

3. Slowly raise the test drum pressure and observe the

opening point. The set pressure on air or steam is the

"pop point" while on water it is the first continuous flow.

4. If necessary reduce the test drum pressure and adjust

the SPRING ADJUSTING SCREW. Repeat this until the

valve opens at the required pressure, designated as

"Cold Differential Set Pressure." At the desired setting,

torque the JAM NUT to 25 FT. LBS. and assemble CAP

and GASKET for tightness testing. Check set point once

more after locking JAM NUT.

NEVER ADJUST THE SPRING SETTING WHEN THE

PRESSURE UNDER "THE VAL VE IS NEAR ITS POPPING

POINT; AS THE BODY SEA T AND DISC SEA T MIGHT

SCORE AND/OR GALL. ALWAYS LOWER THE PRES-

SURE IN THE VALVE AT LEAST 25 PERCENT BELOW

POPPING PRESSURE BEFORE MAKING ADJUST-

MENTS. THIS WILL PUT A LOADING ON THE SEA TfNG

SURFACES, THUS PREVENTING ROTATION AND DAM-

AGE. SEAT TIGHTNESS TESTING

SEAT TIGHTNESS TESTING

NOTE: The valve must be checked for seat leakage after the

set pressure has been checked. Excessive leakage could

lead to fouled or inoperable valves, serious product loss and

could be hazardous to personnel and equipment.

1. The valve can be tested for tightness on the test stand by

increasing vessel pressure to the required test pressure

and observing the valve outlet for evidence of leakage.

The following is an overview of the test procedures used.

Metal Seated Valves:

Metal seated valves shall be tested at 90% of set pressure

when the set pressure is greater than 50 psig; they shall be

tested at 5 psig below set pressure when the set pressure is

less than or equal to 50 psig.

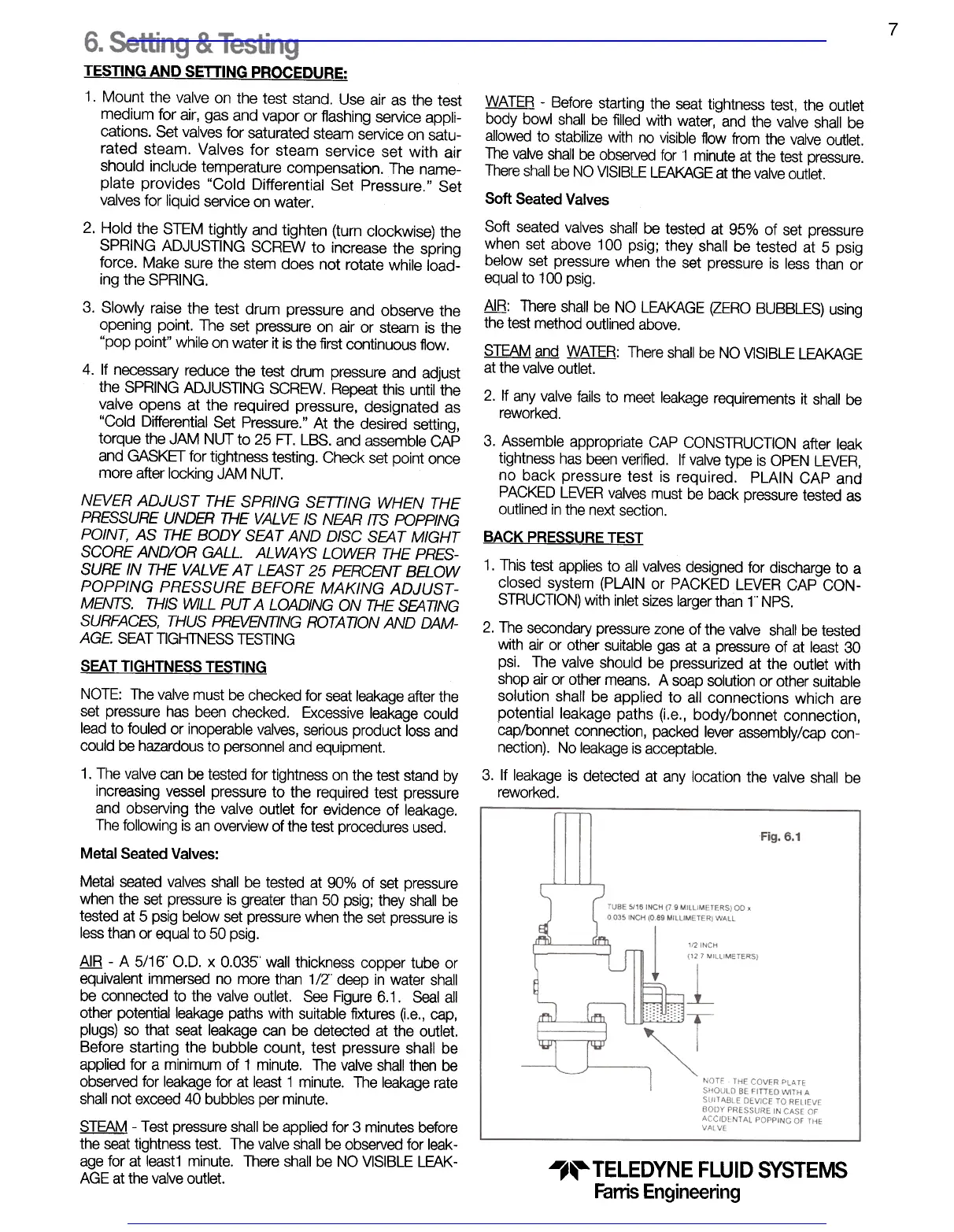

A!B -A 5/16' 0.0. x 0.035' wall thickness copper tube or

equivalent immersed no more than 1/2" deep in water shall

be connected to the valve outlet. See Figure 6.1. Seal all

other potential leakage paths with suitable fixtures (i.e., cap,

plugs) so that seat leakage can be detected at the outlet.

Before starting the bubble count, test pressure shall be

applied for a minimum of 1 minute. The valve shall then be

observed for leakage for at least 1 minute. The leakage rate

shall not exceed 40 bubbles per minute.

STEAM -Test pressure shall be applied for 3 minutes before

the seat tightness test. The valve shall be observed for leak-

age for at least1 minute. There shall be NO VISIBLE LEAK-

AGE at the valve outlet.

Visit www.boighill.com to request a quote.

Visit www.boighill.com to request a quote.

Loading...

Loading...