4

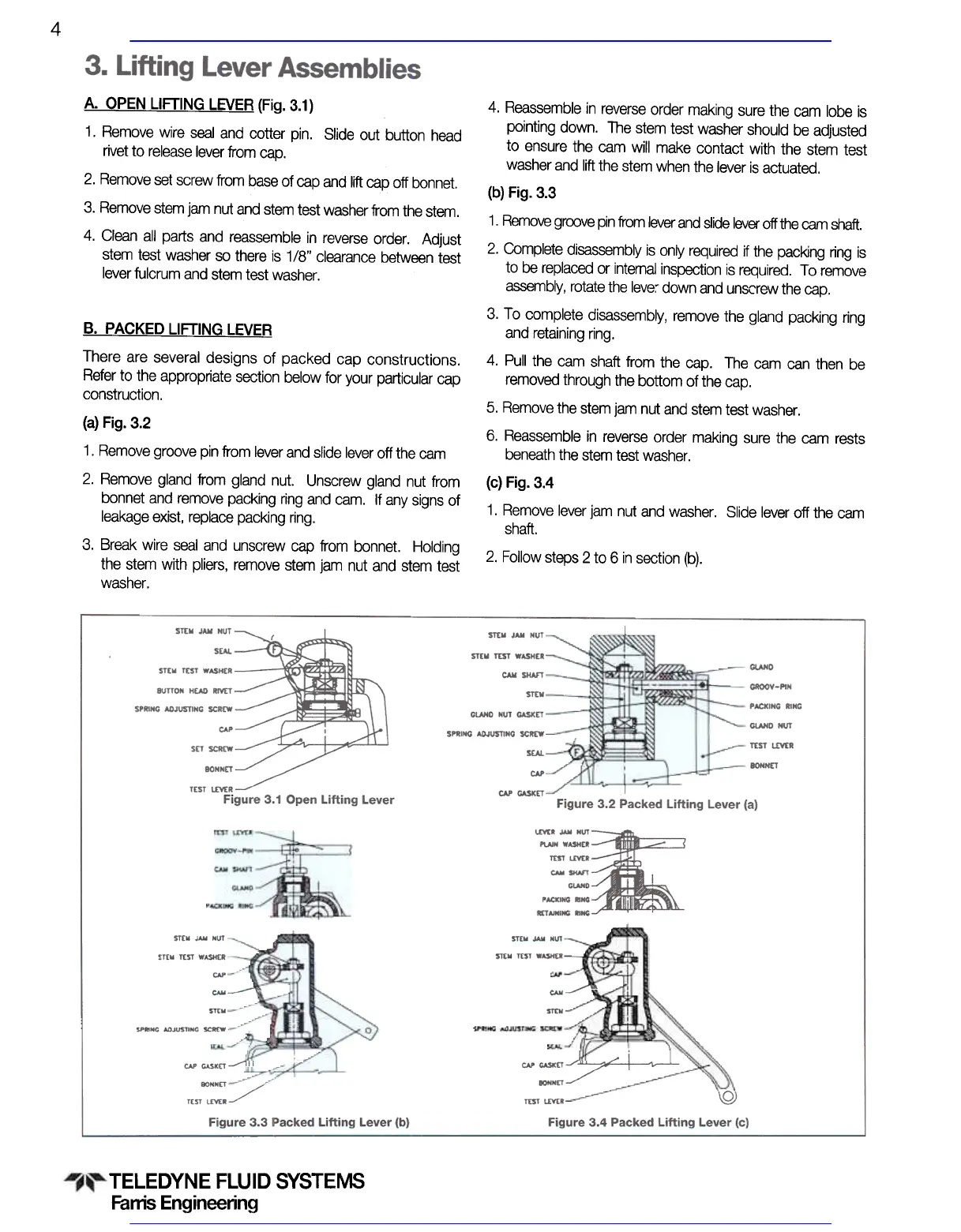

B. PACKED LIFTING LEVER

There are several designs of packed cap constructions.

Refer to the appropriate section below for your particular cap

construction.

(a) Fig. 3.2

1 .Remove groove pin from lever and slide lever off the cam

2. Remove gland from gland nut. Unscrew gland nut from

bonnet and remove packing ring and cam. If any signs of

leakage exist, replace packing ring.

3. Break wire seal and unscrew cap from bonnet. Holding

the stem with pliers, remove stem jam nut and stem test

washer.

4. Reassemble in reverse order making sure the cam lobe is

pointing down. The stem test washer should be adjusted

to ensure the cam will make contact with the stem test

washer and lift the stem when the lever is actuated.

(b) Fig. 3.3

1 .Remove groove pin from lever and slide lever off the cam shaft.

2. Complete disassembly is only required if the packing ring is

to be replaced or intemal inspection is required. To remove

assembly, rotate the leve, down and unscrew the cap.

3. To complete disassembly, remove the gland packing ring

and retaining ring.

4. Pull the cam shaft from the cap. The cam can then be

removed through the bottom of the cap.

5. Remove the stem jam nut and stem test washer.

6. Reassemble in reverse order making sure the cam rests

beneath the stem test washer.

(c) Fig. 3.4

1. Remove lever jam nut and washer. Slide lever off the cam

shaft.

2. Follow steps 2 to 6 in section (b).

STEil JAIl NUT

STEil TEST WASNER

CAIISHArT

STEIl

GlAND

CRDDV-PlN

PACKING RING

CLAND NUT

TEST LEYER

BONNET

SPRING ADJUSTING SCREW

SEAL

CAP

CAP GASKET

Figure 3.2 Packed Lifting Lever (a)

STEM TEST -.sHEW

CAM mu

ST[W JAW WUT

!T[W ftST WASHER

CAP

CAW~

STEW

CAP CASK£T 111 i

~NN£T

./

CAP GAS«[T---:'" ~ i !-

_MET /" .

rm l£VtR \Q)

Figure 3.4 Packed Lifting Lever (c)

TEST l£VER ~

Figure 3.3 Packed Lifting Lever (b)

TELEDYNE FLUID SYSTEMS

Farris Engineering

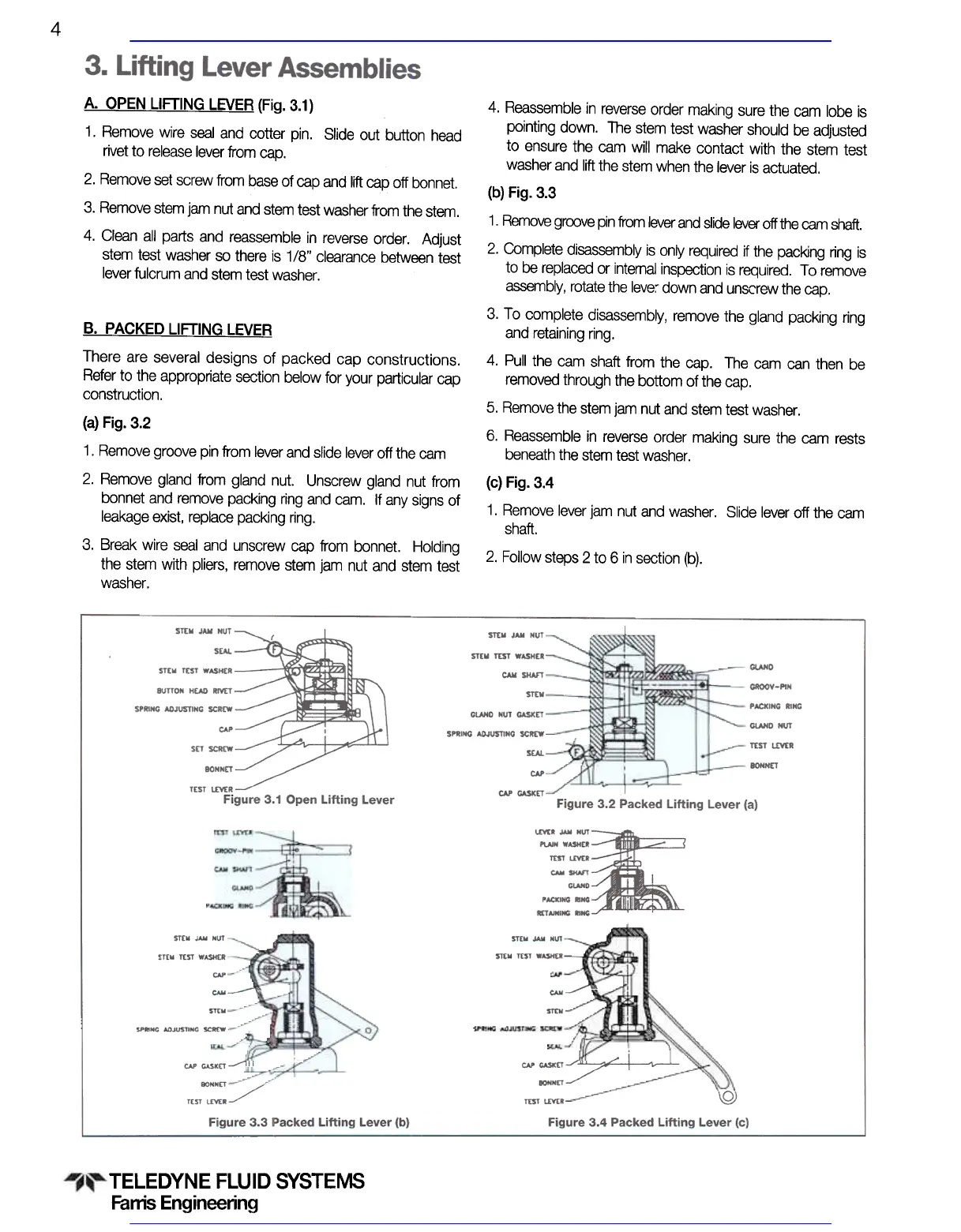

A. OPEN LIFTING LEVER (Fig. 3.1)

1. Remove wire seal and cotter pin. Slide out button head

rivet to release lever from cap.

2. Remove set screw from base of cap and lift cap off bonnet.

3. Remove stem jam nut and stem test washer from the stem.

4. Clean all parts and reassemble in reverse order. Adjust

stem test washer so there is 1/8" clearance between test

lever fulcrum and stem test washer.

Visit www.boighill.com to request a quote.

Visit www.boighill.com to request a quote.

Loading...

Loading...