5

4. Lapping Procedure

(For metal seats only; does not apply to a-ring seat seal valve)

1. The finish on the body seat and disc are critical to seat

tightness. After the parts have been cleaned both parts

should be lapped to remove all blemishes and score

marks. This can be done on an automatic lapping

machine or by hand using a cast iron lapping block or

Pyrex lapping glass which is known to have a perfectly

flat surface.

that has been lapped off from the body seat in order to

maintain the critical parts respective relationship.

5b. (1890/95/96M only) Remove the same thickness of

material from the bottom face of the guide as that has

been lapped off from the body seat.

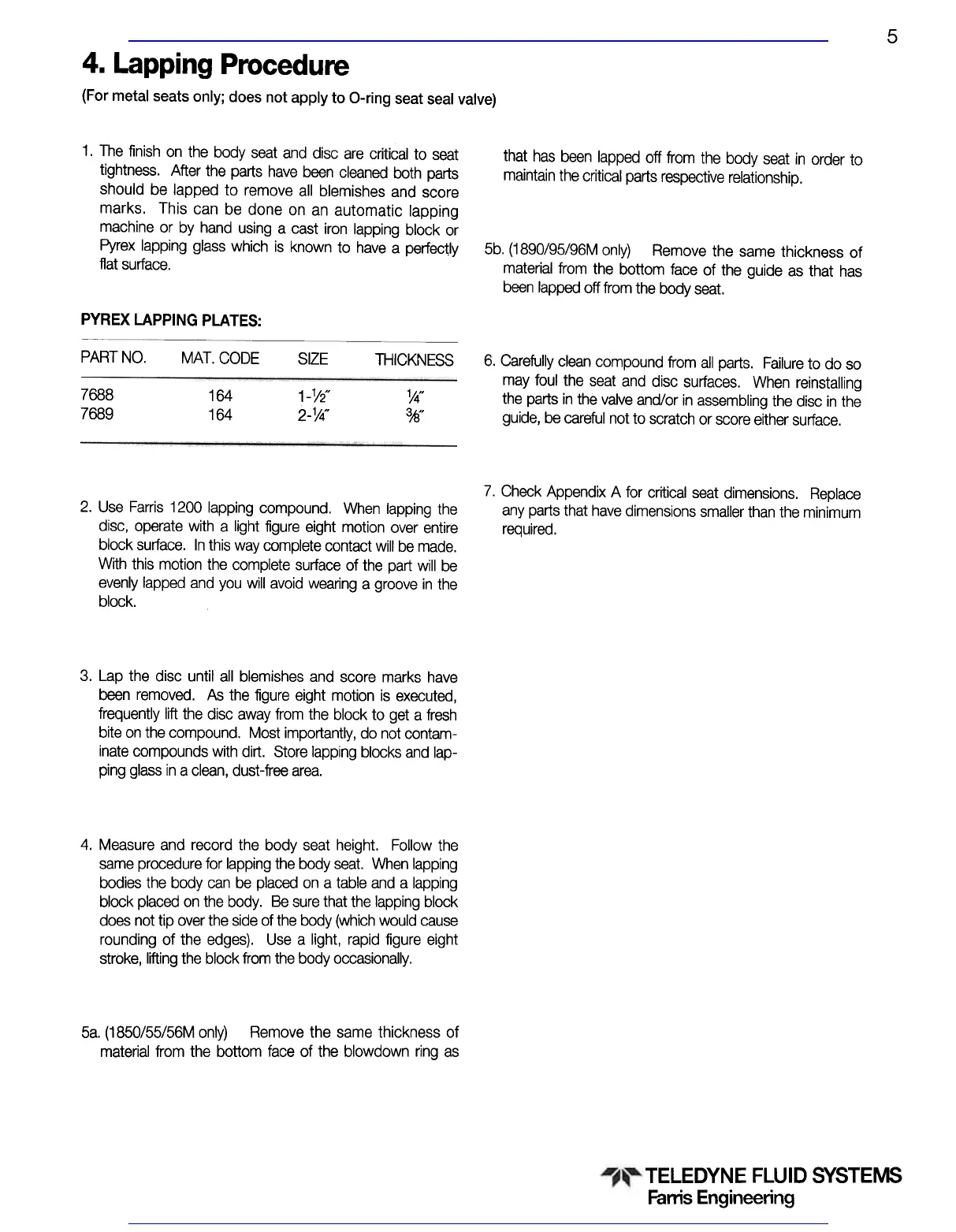

PYREX LAPPING PLATES:

PART NO.

MAT. CODE

SIZE

THICKNESS

6. Carefully clean compound from all parts. Failure to do so

may foul the seat and disc surfaces. When reinstalling

the parts in the valve and/or in assembling the disc in the

guide, be careful not to scratch or score either surface.

7688

7689

164

164

1-1;2'

2-1f4-

1;4"

%"

7. Check Appendix A for critical seat dimensions. Replace

any parts that have dimensions smaller than the minimum

required.

2. Use Farris 1200 lapping compound. When lapping the

disc, operate with a light figure eight motion over entire

block surface. In this way complete contact will be made.

With this motion the complete surface of the part will be

evenly lapped and you will avoid wearing a groove in the

block.

3. Lap the disc until all blemishes and score marks have

been removed. As the figure eight motion is executed,

frequently lift the disc away from the block to get a fresh

bite on the compound. Most importantly, do not contam-

inate compounds with dirt. Store lapping blocks and lap-

ping glass in a clean, dust-free area.

4. Measure and record the body seat height. Follow the

same procedure for lapping the body seat. When lapping

bodies the body can be placed on a table and a lapping

block placed on the body. Be sure that the lapping block

does not tip over the side of the body (which would cause

rounding of the edges). Use a light, rapid figure eight

stroke, lifting the block from the body occasionally.

5a. (1850/55/56M only) Remove the same thickness of

material from the bottom face of the blowdown ring as

TELEDYNE FLUID SYSTEMS

Farris Engineering

Visit www.boighill.com to request a quote.

Visit www.boighill.com to request a quote.

Loading...

Loading...