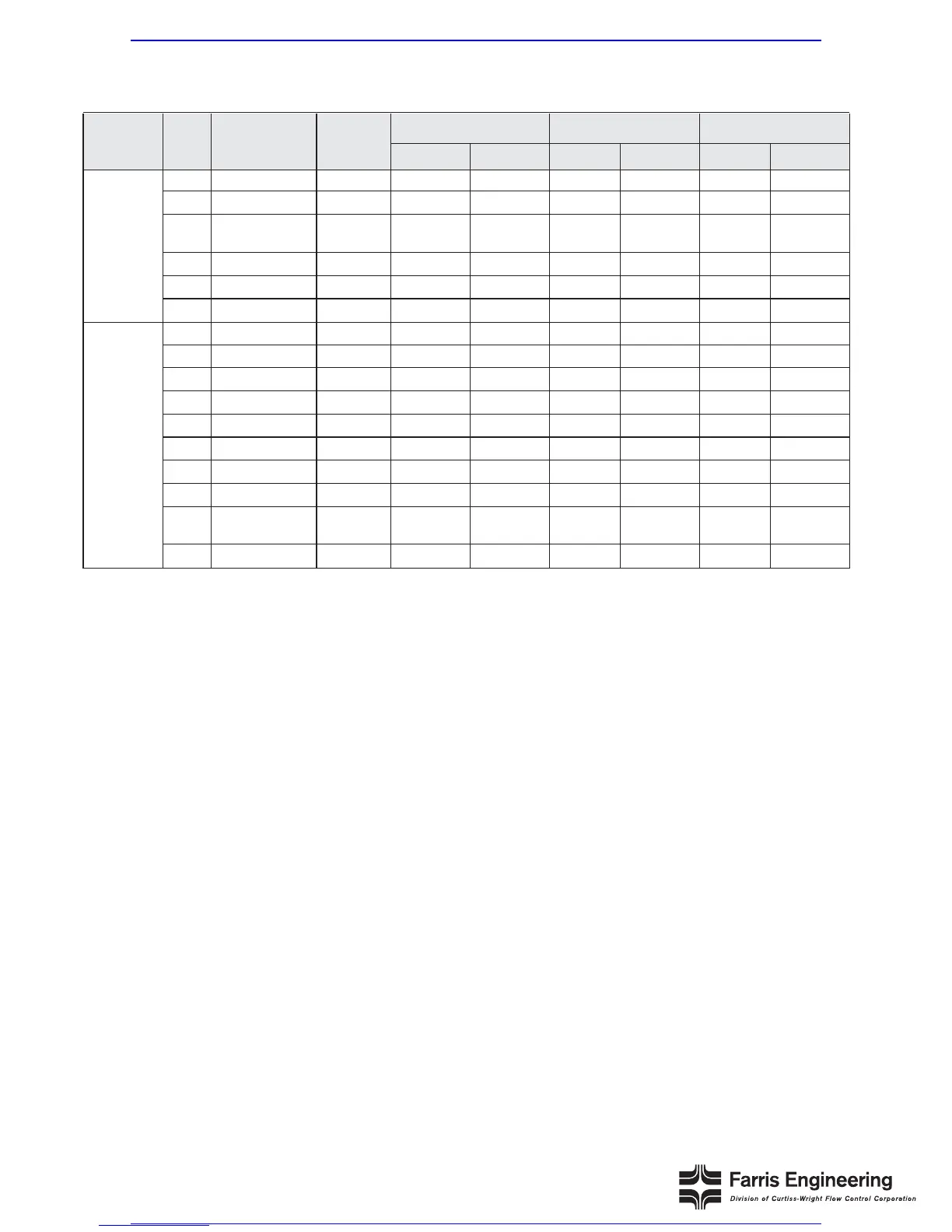

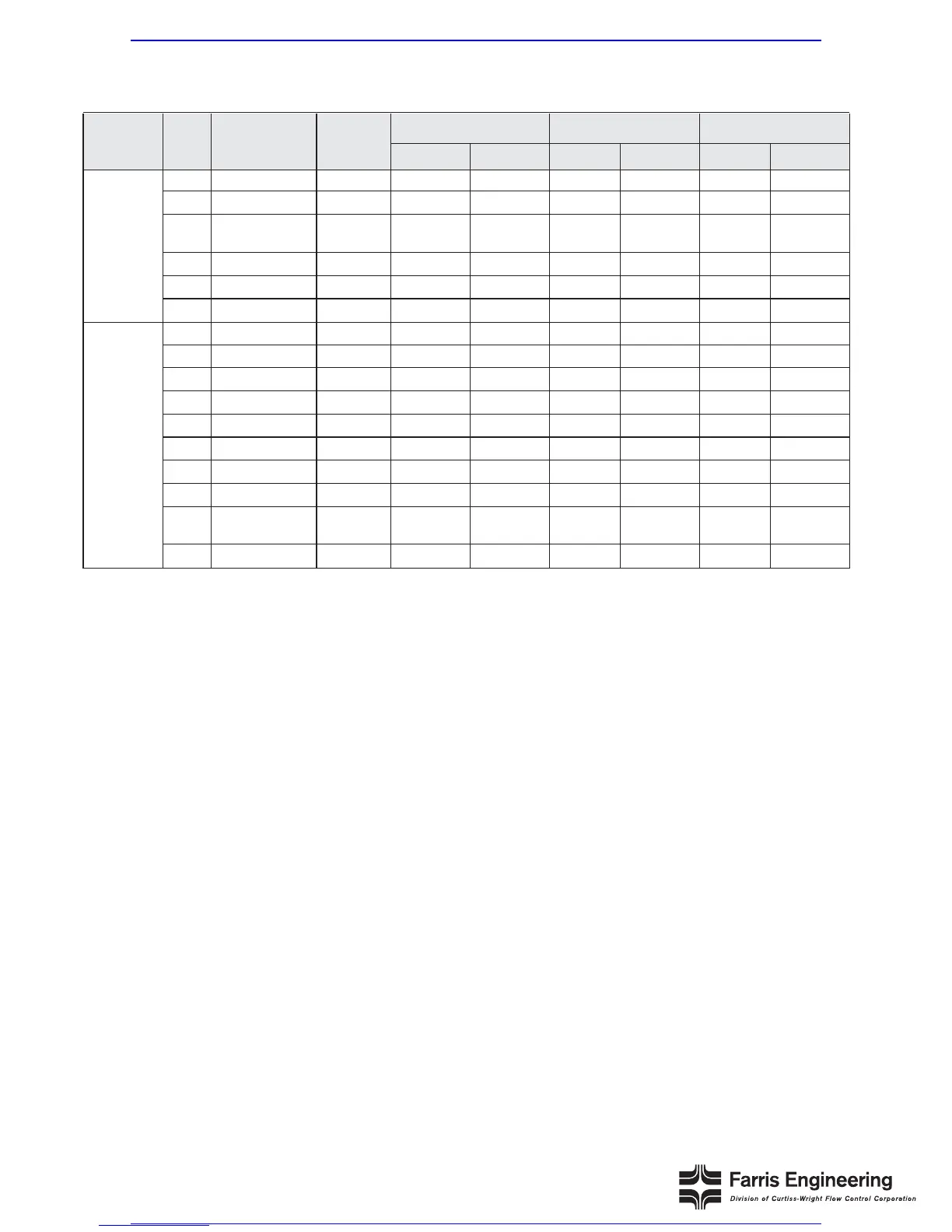

Accessories

Cap Construction: M70 Open Lever, M40 Packed Lever

General Notes:

1. Any part denoted with a dash is standard material. 2. S4 trim is suitable for cryogenic service.

Cap

Construction

Item

No.

Part

Name

Standard

Materials

316 St. St.

S4

S7

Monel

M1 & M2

M4

Hastelloy C

H1 & H2

H4

M70

Open

Lever

M40

Packed

Lever

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Test Lever

Cap, Open Lever

Stem Test

Washer

Stem Jam Nut

Button Head Rivet

Set Screw

Test Lever

Cap, Packed Lever

Stem Test Washer

Stem Jam Nut

Cam

Gland

Gland Nut

Packing Ring

Gland Nut Gasket

Groove Pin

Iron

Iron

St. St.

St. St.

Steel

Steel

Steel

Steel

St. St.

St. St.

St. St.

St. St.

St. St.

Graphite

Flexible

Graphite

Steel Plt’d

––

––

316

St. St.

316

St. St.

––

––

––

316

St. St.

316 St. St.

316 St. St.

316 St. St.

316 St. St.

316 St. St.

––

Teflon Coated

Ceramic Fiber

––

––

––

––

––

––

––

––

––

––

––

––

––

––

––

Teflon Coated

Ceramic Fiber

––

––

––

––

––

––

––

––

––

––

––

––

––

––

––

––

––

––

––

Monel

Monel

––

––

––

Monel

Monel

Monel

Monel

Monel

Monel

––

Teflon Coated

Ceramic Fiber

––

––

––

––

––

––

––

––

––

––

––

––

––

––

––

––

––

––

––

Hast. C

Hast. C

––

––

––

Hast. C

Hast. C

Hast. C

Hast. C

Hast. C

Hast. C

––

Teflon Coated

Ceramic Fiber

––

5

2. Disassembly of Valves

Dismantling

1. Place the valve at a suitable height. The work

surface should be clean, and strong enough to

handle the weight of the parts and the forces

required during disassembly and assembly.

2. Mount valve vertically in a vise using the flats on

the valve body.

3. Remove wire seal. Unscrew cap by turning counter-

clockwise. (For packed and open lever cap con-

struction, refer to the section on Lifting Lever

Assemblies.) Remove the cap gasket.

4. Using a smooth jaw wrench, hold the spring

adjusting screw and remove the jam nut (spring

adjusting screw).

5. Measure the distance from the top of the spring

adjusting screw to the top of the bonnet, or count

the number of turns of the spring adjusting screw.

Use this measurement when reassembling the

valve to approximately duplicate the original set

pressure.

6. Remove the spring adjusting screw by turning

counterclockwise.

7. Thread a pipe into the outlet and turn the bonnet

counterclockwise, removing it from the body.

Alternatively, the bonnet can be held in a vise and

a wrench can be used on the body to loosen it.

8. Lift out the stem with spring and buttons attached.

Remove upper button, spring and lower button

from stem.

9. Remove the guide gasket.

10. Remove the body and trim assembly from the vise.

Place one hand on top of the guide and invert the

assembly, allowing the guide which contains the

disc holder and disc to drop free of the body. Turn

the guide upright and allow the disc holder to slide

out of the guide, being careful not to drop either

piece. Remove disc from disc holder and body

gasket from the body.

11. Clean all parts and threaded surfaces thoroughly.

Replace all gaskets.

12. Lap the body seat and disc surfaces. See Section

3 for lapping procedure and Appendix A for critical

dimensions.

Loading...

Loading...