5. Setting & Testing4. Assembly

8

1. Refer to Figure 1.2 for construction details, and

Figures 1.5 and 1.6 for open lever and packed

lever cap construction details.

2. Verify that all parts required are grouped for assem-

bly. Visually inspect all parts, paying close attention

so that the body and disc seats are clear of imper-

fections and all parts are clean. Special attention

should also be given to the guide, checking for any

dirt or scale in exit holes and undercuts, and making

sure that guide surface is in good condition.

3. All threaded surfaces should be lubricated with

Bostik Never-Seez or equivalent. Sealing surfaces,

such as body and cap gasket, should be lightly

coated with a sealant such as Rectorseal pipe

thread sealant. Use Bostik Never-Seez or equiva-

lent on valves for steam service.

Sliding and bearing surfaces such as disc holder/

guide and disc-to-disc holder contact surfaces

should be left clean and assembled without lubricants.

4. Place disc in disc holder, making sure V-notch is

facing the stem radius. Insert assembly into guide.

Install body and lower guide gasket on the body.

5. Hold guide/disc holder assembly horizontally in

your left hand and insert body, being careful not to

damage disc or body seating surfaces.

6. Mount body/guide assembly vertically in a vise,

gripping body securely by the flats. Install guide

gasket on top of guide flange.

7. Place spring and spring buttons onto stem assembly

and insert into disc holder. Hold in place in vertical

position.

8. Place bonnet over assembled parts and screw

down handtight onto the body. For C and D orifices,

torque the bonnet to the body to 140-160 ft. lbs. For

E, F, and G orifices, torque should be 180-200 ft. lbs.

9. Thread the jam nut onto the spring adjusting screw.

Place spring adjusting screw over stem and into

bonnet. Hand tighten spring adjusting screw until it

contacts spring and lightly compresses it. Compress

spring to the same point as in disassembly, if same

set pressure is required. Install cap gasket.

10. Test the valve according to the procedure described

in Section 5. After testing, install the appropriate

cap or lever assembly.

Testing Procedures

Testing consists of adjusting the valve set pressure,

performing a seat leakage test and a backpressure

test. The set pressure test is always performed first.

Set Pressure Test

1. Set pressure testing must always be performed

using the appropriate test fluid shown in Table 2.

2. Mount valve on test stand, making a note of set

pressure and cold differential test pressure (CDTP).

The valve will be set at the CDTP.

3. Hold the stem tightly and tighten (clockwise) spring

adjusting screw to increase the set pressure. Make

sure stem does not rotate while tightening the

adjusting screw as this can damage seat and disc.

4. Slowly raise test drum pressure and observe the

opening (set) pressure. The set pressure on air and

steam is the point at which it makes an audible

pop. For water, the set pressure is the first continu-

ous flow of liquid that forms a stream approximately

1/16” thick perpendicular to the outlet.

5. If necessary, reduce test drum pressure 25% below

the opening pressure and adjust the spring adjusting

screw. Repeat until the valve opens at the required

pressure, designated as the cold differential test

pressure (CDTP). The set pressure tolerance is

equal to +/-3% of set pressure.

CAUTION: Never adjust the spring when the

pressure under the valve is near its popping point as

the body seat and disc may score and/or gall. Always

lower the pressure in the test vessel at least 25%

below popping pressure before making adjustments.

This will put a loading on the seating surfaces and

prevent rotation and damage.

6. Lock the jam nut in place and pop valve once more

to ensure set pressure adjustment was not disturbed.

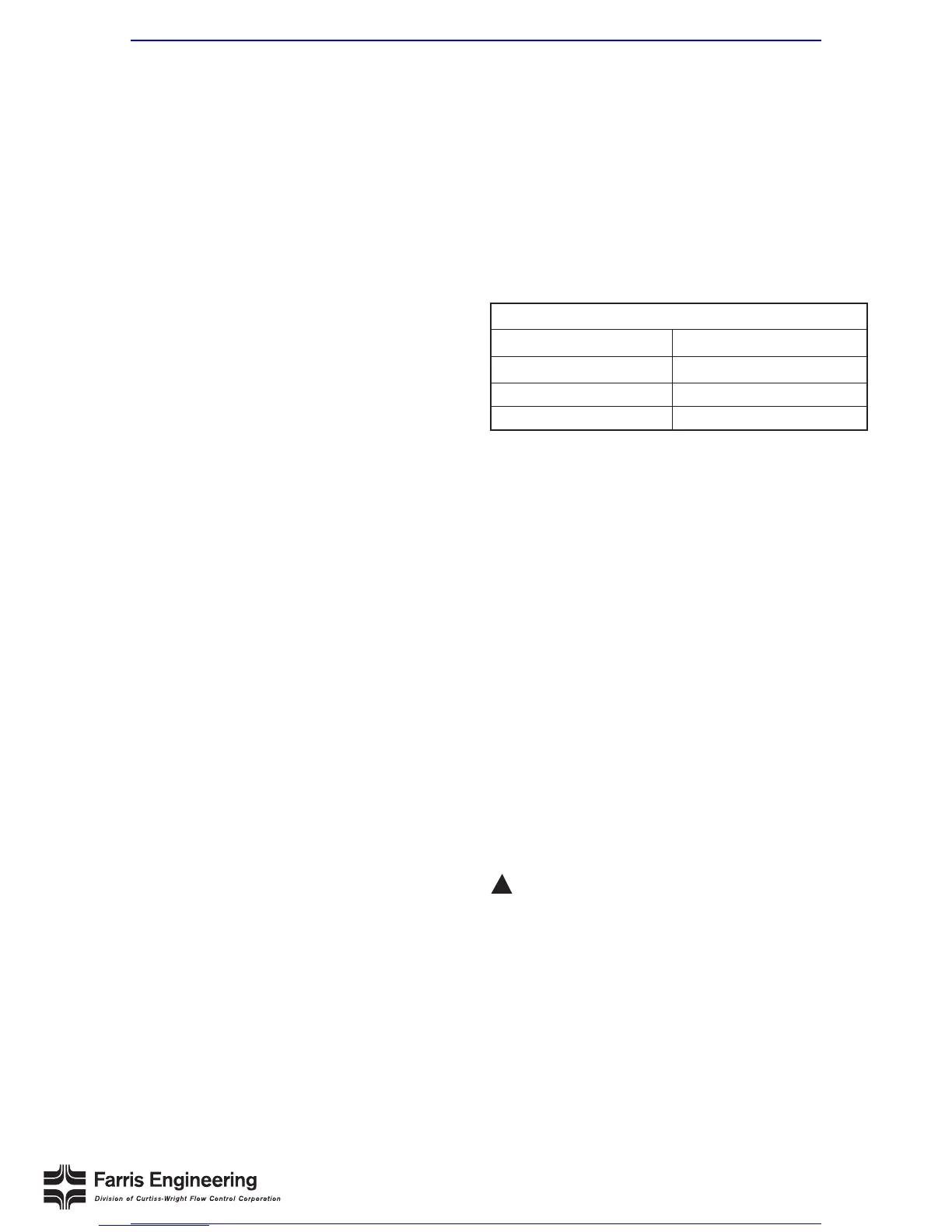

PRESSURE RELIEF VALVE TEST FLUIDS

Service Fluid Test Fluid

Air, gas & vapor Air or gas

Steam Steam*

Liquid Water

Table 2

*air may be used for ASME Code Section VIII valves.

!

Loading...

Loading...