3. Refacing and Lapping

7

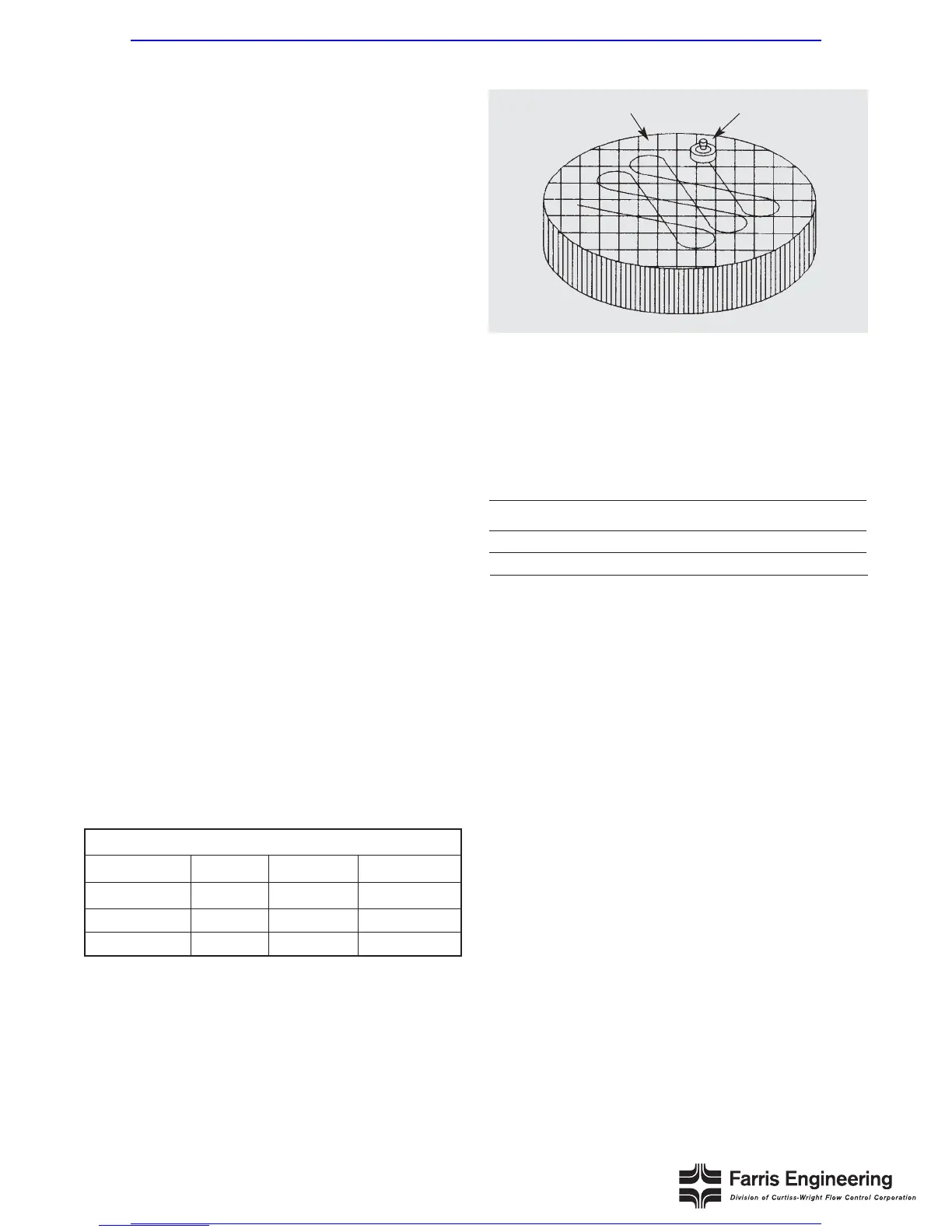

Figure 1.7

Table 1 Farris Lapping Compounds

Lapping Plate

Part

Body Refacing

(when necessary)

1. True up body by means of an indicator, ensuring

that body bore and outside diameter are concentric

with each other within 0.002” full indicator reading.

2. Machine a light cut across the seat until damaged

areas are removed. The seat should be machined

to the smoothest possible finish. Rigidity of the

cutting tool is critical.

3. Relap to a mirror finish.

4. Discard and replace the body when the minimum

requirement on dimension B, listed in Appendix A,

is not met.

5. Bodies on O-ring seat valves do not require

refacing. Contact surfaces should be cleaned of

any dirt or scale and lightly lapped.

Disc Relapping

(metal and Teflon discs)

1. The disc should not be refaced, only relapped.

2. Discard and replace the disc when disc thickness

becomes less than dimension A, listed in Appendix

A.

Lapping Compounds

The three grades of Farris Lapping Compounds are

prepared especially for the requirements of pressure

relief valves. These are the only compounds recom-

mended for achieving extreme valve tightness.

Lapping Procedures

(manual)

1. Use a cast iron lapping block or Pyrex lapping glass

which is known to have a perfectly flat face.

Pyrex Lapping Plates

Part No. Material Code Size Thickness

7688 164 1 1/2” 1/4”

7689 164 2 1/4” 3/8”

2. Select the appropriate lapping compound. When

lapping the disc, operate with a light figure eight

motion over entire block surface for complete

contact. See Figure 1.7. With this motion, the

complete surface of the part will be evenly lapped

and you will avoid wearing a groove in the block.

3. Lap disc until all blemishes and score marks have

been removed. As you execute the figure eight

motion, frequently lift disc away from the block to

get a fresh bite on the compound. Most important,

do not contaminate compounds with dirt. Keep the

lid on the lapping compound when not in use.

Use only clean applicators to transfer the lapping

compound from jar to lapping glass. Store lapping

blocks and lapping glass in clean, dust-free area.

4. Follow the same procedure for lapping body seat.

Place the body on a table and a lapping block on

the body. Be sure that lapping block does not tip

over the side of the body (this would cause round-

ing of the edges). Use a light, rapid figure eight

stroke, lifting the block from the body occasionally.

5. Carefully clean compound from all parts. Failure to

do this may foul seat and disc surfaces. When

reinstalling parts in the valve and assembling disc

in the guide, be careful not to scratch either surface.

6. Clean the lapping glass.

FARRIS LAPPING COMPOUNDS

PART NO. GRADE FINISH SIZE

18632X1(055) 3F Roughing 1/2-oz. tube

18633X1(075) 38-500 Medium 1/2-oz. tube

18634X1(105) 38-1200 Final 1/2-oz. tube

Loading...

Loading...