G2 MANOEUVRES AND CONTROLS TO STABILIZE

THE VEHICLE

The outriggers rams prevent damaging stresses both to the frame and to the

vehicle suspensions on which the crane is mounted to and assure the stability

of the unit during load handling.

Be very careful when stabilizing the vehicle; make sure that no one is or tran-

sits in close proximity of the working area of the outriggers.

(!) ATTENTION (!)

The crane stability is maintained by the maximum extension of the outrigger

supports

, by the solidity of the base underneath the plates of the outrigger rams

and by the observance of the capacity plates. To check the maximum working

pressure see Paragraph D0.1 Technical data

Check that the outrigger rams are applied on a solid base; if necessary use

larger outrigger base plates (available on request) to avoid sinking.

When stabilization is complete the wheels of the vehicle must still be in contact

with the ground and the suspensions must not be fully unloaded.

Stabilize the crane so as to operate on a horizontal plane with a maximum

tolerance of 1,5 degrees.

Whil

e loading, it may be necessary to vertically adjust the outrigger rams to

prevent an overload on the outriggers, then stabilize again.

While unloading, the outrigger rams may not be perfectly in contact

with the ground because of a rise in the suspension; it is therefore

recommended to stabilize the vehicle during operation to avoid an

overturn.

G2.1 Supplementary beam; manual extension

of the outrigger supports

(!) ATTENTION (!)

To manoeuvre the supports hands must only grab the handles

placed on the outrigger rams.

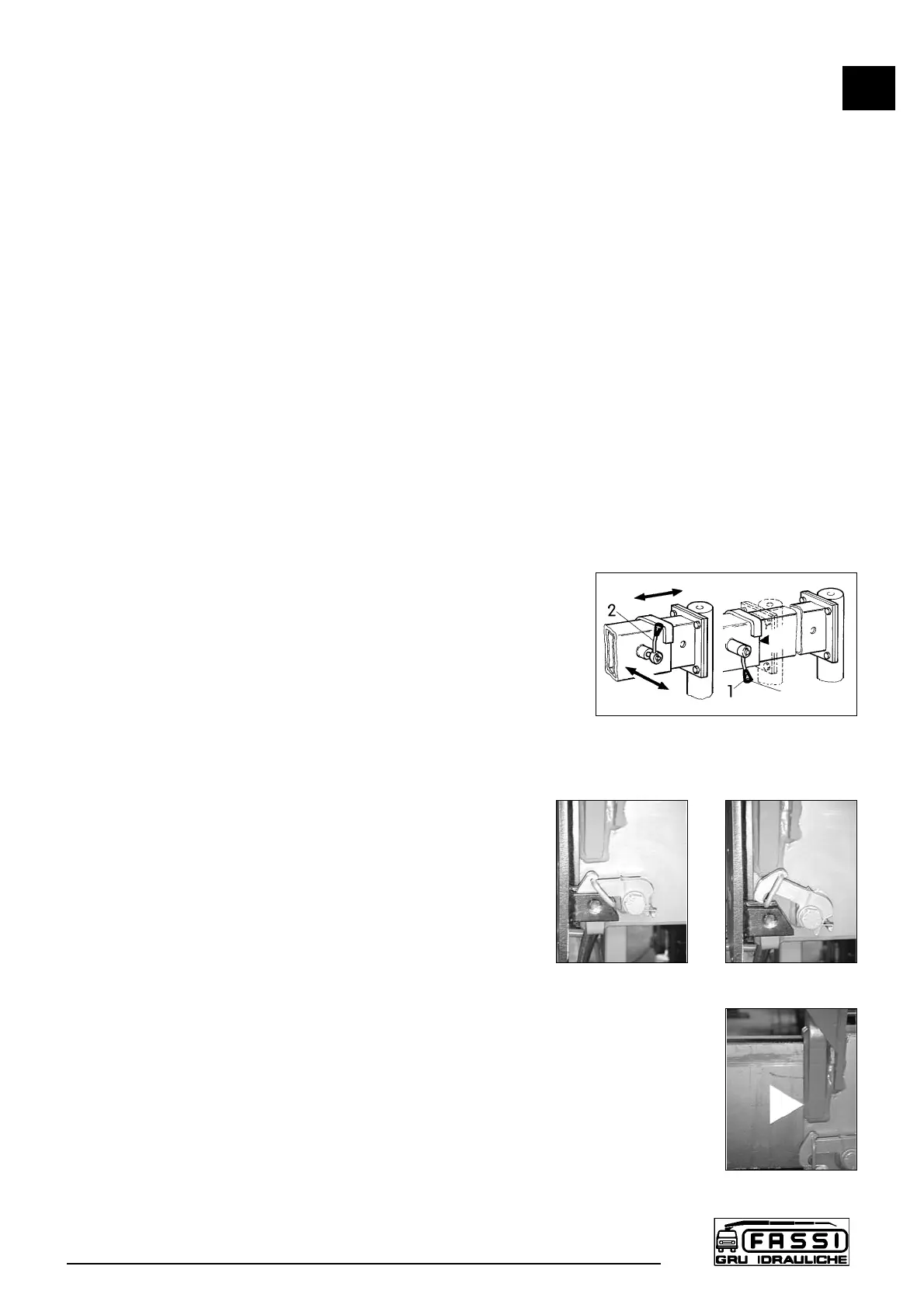

Position the lever B of the outrigger locking device from the

pos. 1 to the pos. 2 (released position) fig. 13.

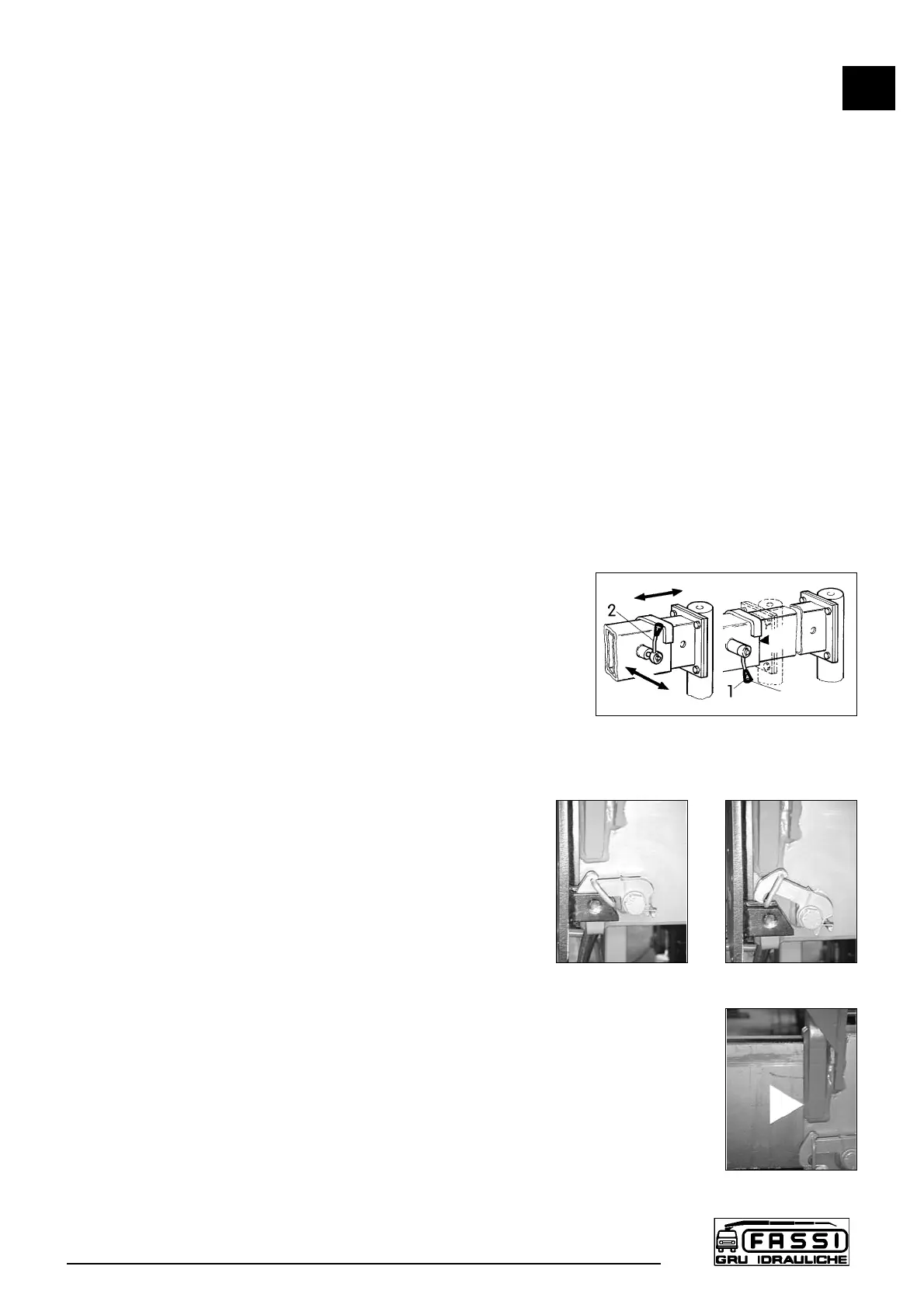

Put the lever A of the outrigger security check from the posi-

tion of the fig. 14 to the one of the fig. 14a.

Extend the outrigger support from the base and position the

lever B to the pos. 1.

Extend the outrigger support till the coupling of the pin of the

lever B.

By the same sequence, repeat the operations described to extend the other

support.

(!) ATTENTION (!)

The complete extension of the outrigger support is visually indicated by the yellow

triangle which is found at the end of the beam. (Fig.14b)

The outrigger support is locked in position by the security pin; this will ensure the

complete extension of the outrigger support and the impossibility of accidental

movements.

G2

SUPPLEMENTARY BEAMS

F 170A

19

fig. 13

fig. 14

fig. 14a

fig. 14b

Lever B

Loading...

Loading...