MSS

TM

Series

© Copyright 2022 Fluid Equipment Development Company | www.fedco-usa.com

- 43 -

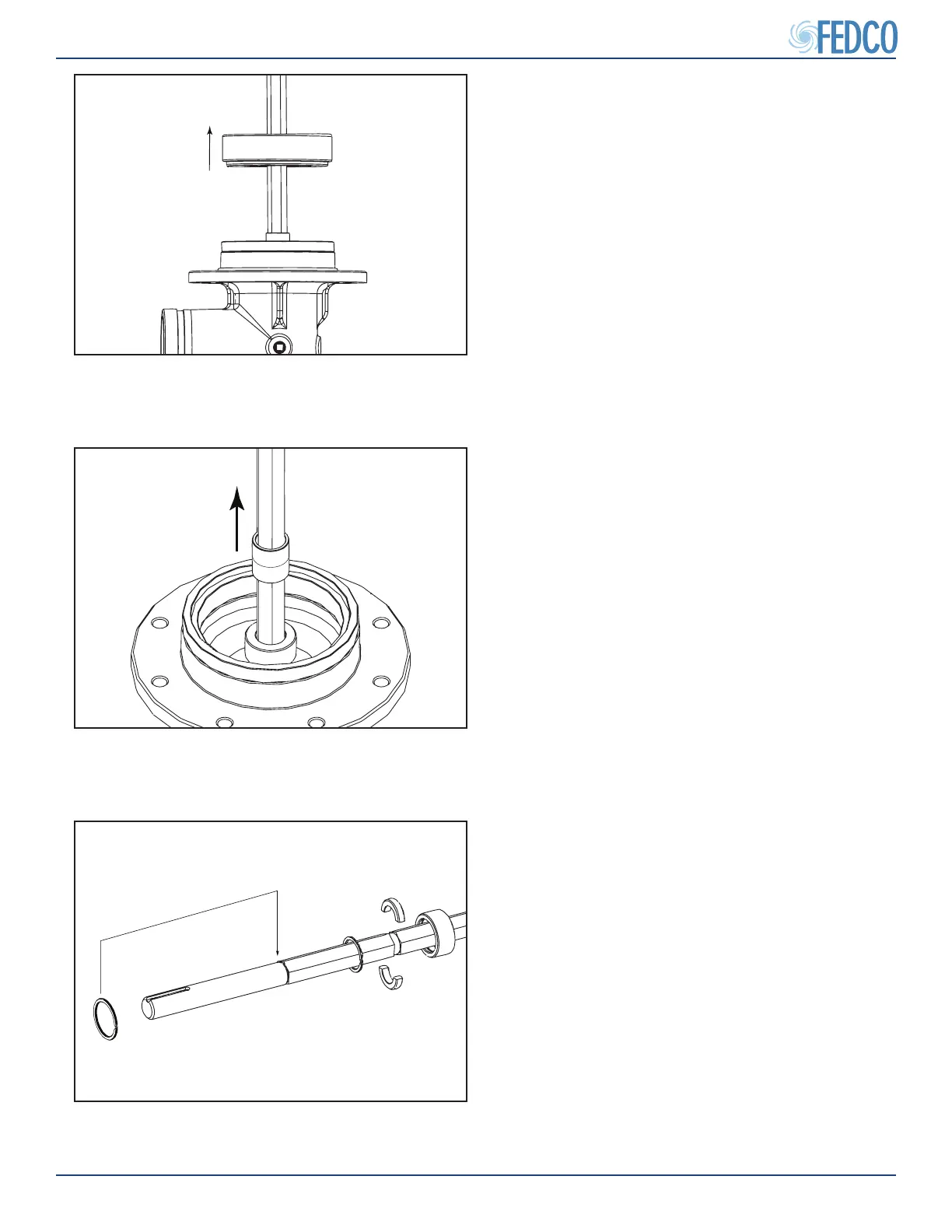

Figure 92 - Shaft Collar Installation

Stage Installation

NOTES: Continue supporting the weight of the

shaft to avoid damage to the mechanical seal.

1. Remove, inspect, and replace the shaft if

necessary.

a. Place the collar sleeve and the retaining

ring onto the pump shaft. Make sure the

collar sleeve’s cup side is facing towards

the motor coupling shaft end.

b. Place the split collar halves onto the pump

shaft and slide the collar sleeve over the

split collar halves.

c. Install the retaining ring into the split collar

sleeve.

d. Install the mechanical seal retaining ring

onto the pump shaft.

NOTES: Only remove pump shaft/ mechanical

seal if necessary.

Figure 91 - First Stage Spacer Removal

7. Inspect the inlet ring for excessive wear.

NOTES: Remove the inlet ring and replace if

necessary. The inlet/ discharge rings are not

included in any eld service kits but can be pur-

chased separately.

8. Remove the rst stage (start) spacer.

NOTES: The rst stage spacer may be dimen-

sionally dierent from the stage spacers and

needs to be kept separately. On some installa-

tions, this start spacer may be engraved to help

distinguish it from standard stock spacers.

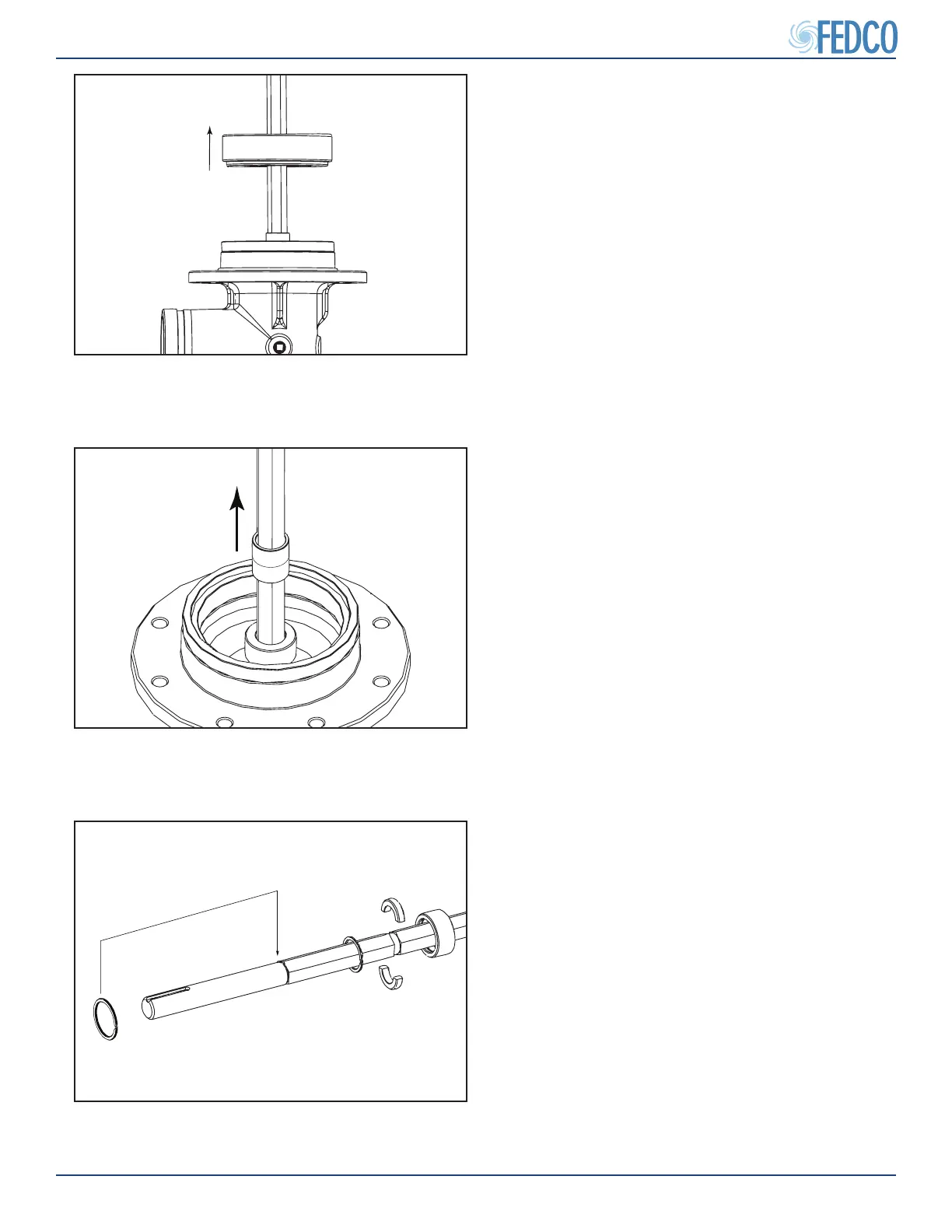

Figure 90 - Starting Stage Removal

6. Remove the rst stage housing (diuser

bowl).

NOTES: The rst stage housing (diuser) can

be identied by the lack of vanes on the bottom

of the bowl. Because this component is dier-

ent than the other diusers it should be kept in

a separate location.

NOTES: The shaft will no longer be supported

by stages and will fall over or cause damage to

the bushing and seal if not supported.

Pump Overhaul Continued

Loading...

Loading...