MSS

TM

Series

© Copyright 2022 Fluid Equipment Development Company | www.fedco-usa.com

- 44 -

Figure 95 - Starting Stage Installation

4. For:

MSS-15/20/30 Pumps:

Install the rst stage housing (diuser bowl)

onto the inlet ring. Note that the rst stage

housing (diuser) can be identied by the

lack of vanes on the bottom of the bowl.

MSS-50/70 Pumps:

Install the rst diuser bowl onto the inlet

ring.

NOTES: Verify diuser bushings have been

pre-installed before assembly.

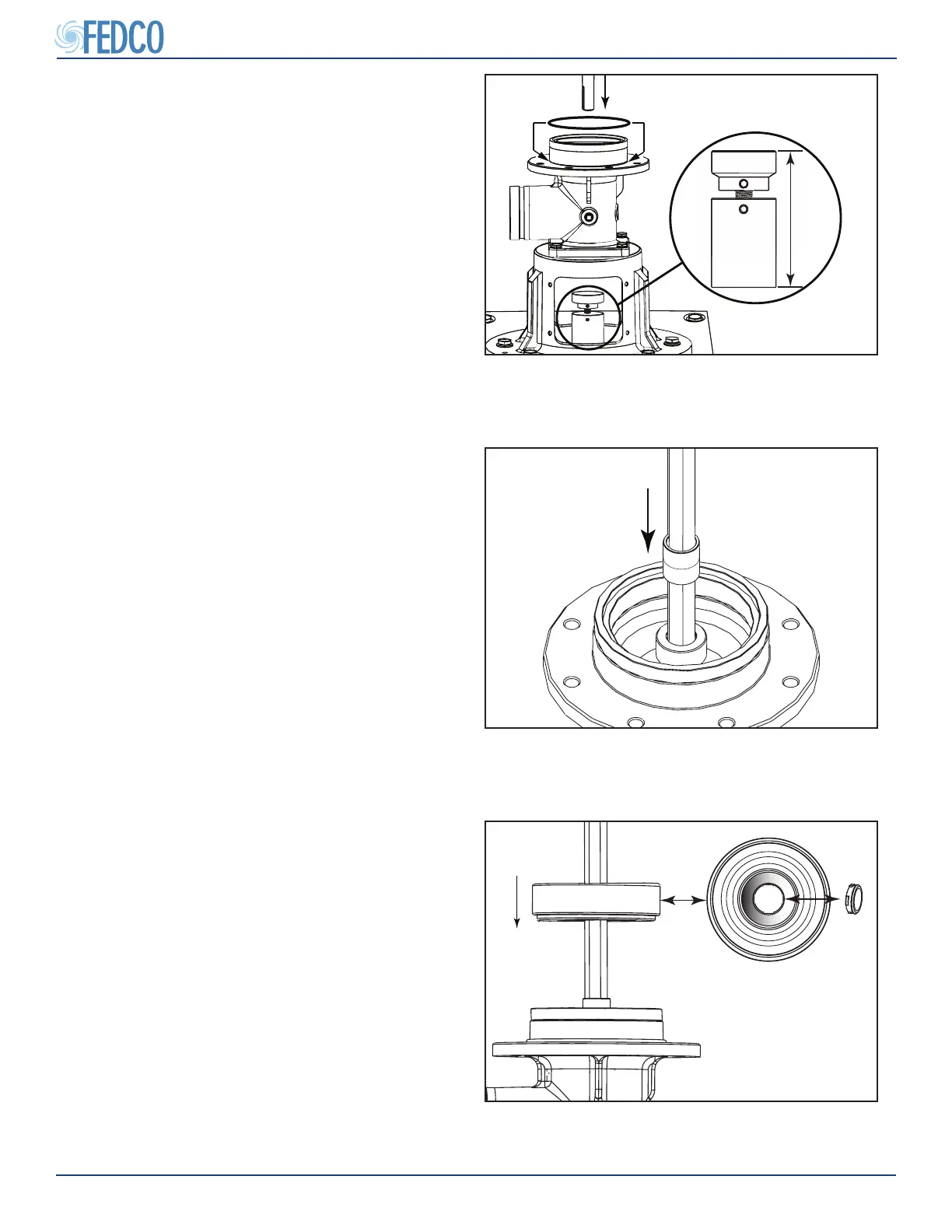

Figure 94 - First Stage Spacer Installation

3. Install the rst stage (start) spacer onto the

pump shaft until it comes into contact with

the shaft collar sleeve.

NOTES: The start spacer must contact the col-

lar sleeve as shown. If the collar sleeve’s cup

side if facing up, it is on upside down.

NOTES: The rst stage spacer is dimension-

ally dierent from the stage spacers. On some

installations, this start spacer may be engraved

to help distinguish it from standard stock spac-

ers.

NOTES: MSS-50/70 stage components may

dier in size/ shape.

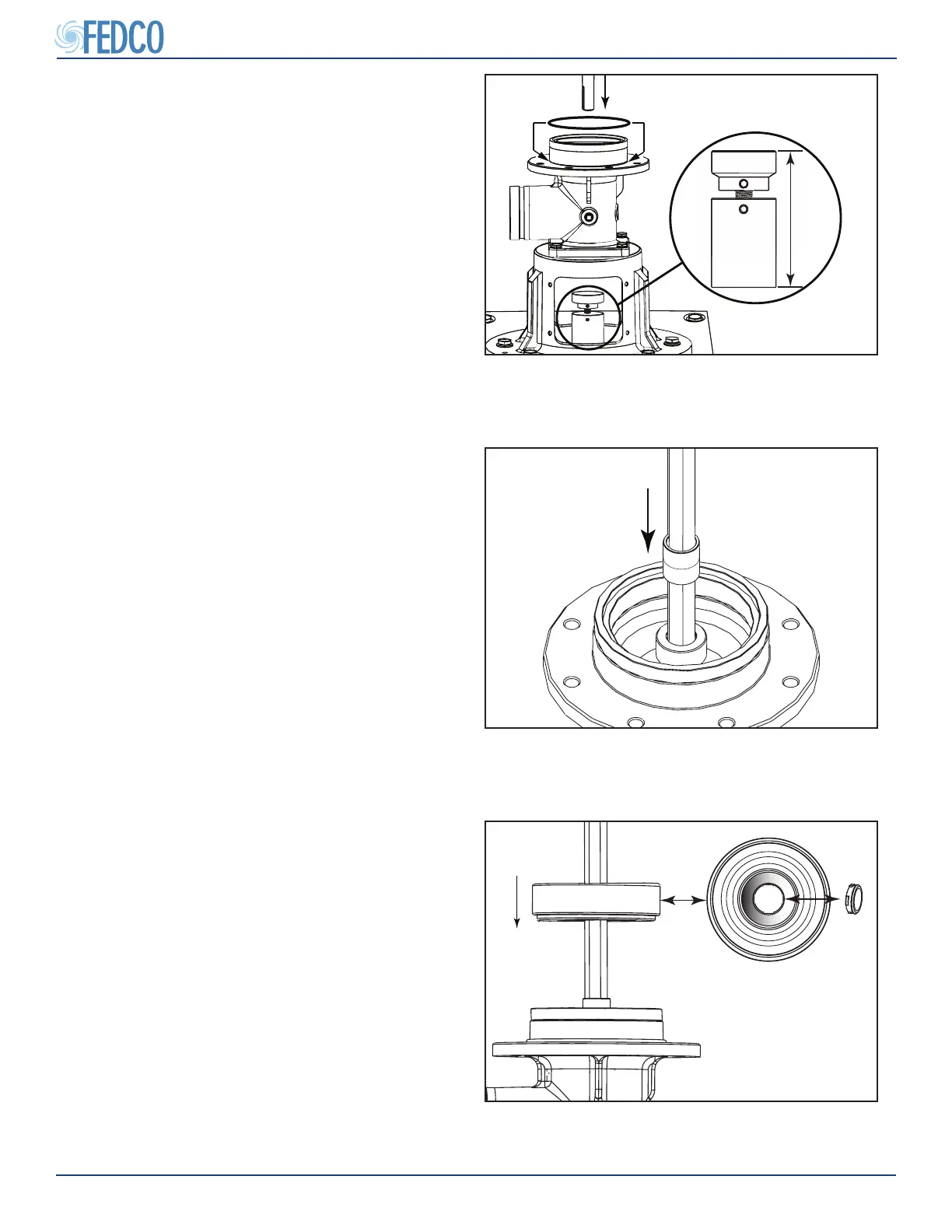

Figure 93 - Shaft Installation

e. Slowly lower the pump shaft into the inlet

until the pump shaft end rests on the gage

block.

2. Lubricate and install the inlet O-ring.

NOTES: Gauge block height should be preset

from the stage removal section. Verify height

before building. Contact FEDCO eld service

for gauge block height if unknown. The pump

serial number must be provided.

Pump Overhaul Continued

Loading...

Loading...