ECONCEPT TECH 25 A

12 EN

cod. 3540I301 - 05/2008 (Rev. 00)

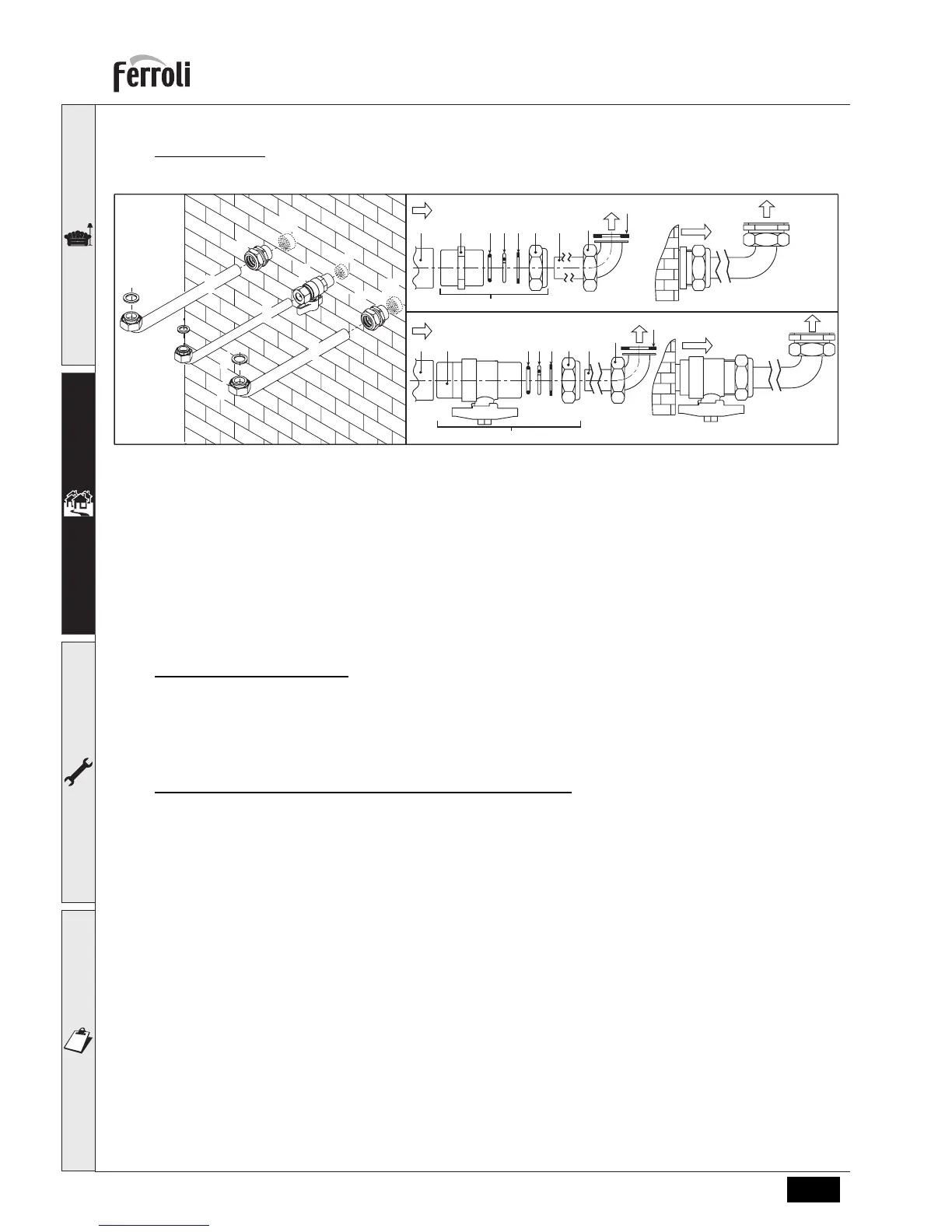

Connection kits

The connection kits shown in fig. 16 are supplied by request.

fig. 16 - Union connection kit

A = 3/4” fitting assembly for Ø18 pipe

B = 1/2” gas cock

c = Gas system connection pipe

d = Heating system connection pipe

e = 3/4” ring - Ø20 hole

f = 1/2” ring for Ø14 pipe

g = Ø24 seal

h = Ø18.5 seal

L = OT 58 nipple

M = O-ring

N = OT 58 stop collar

P = Copper washer

Q = OT58 fitting

R = Ball cock

S = Female sleeve

7 = Gas inlet

10 = System delivery

11 = System return

System water charcteristics

In the presence of water harder than 25° Fr (1°F = 10ppm CaCO

3

), the use of suitably treated water is advisable in order

to avoid possible scaling in the boiler. The treatment must not in any case reduce the hardness to values below 15°F

(Decree 236/88 for uses of water intended for human consumption). Water treatment is indispensable in the case of

very large systems or with frequent replenishing of water in the system. If partial or total emptying of the system be-

comes necessary in these cases, it is advisable to refill it with treated water.

Antifreeze system, antifreeze fluids, additives and inhibitors

The boiler is equipped with an antifreeze system that turns on the boiler in heating mode when the system delivery water

temperature falls under 6°C. The device will not come on if the electricity and/or gas supply to the unit are cut off. If it

becomes necessary, it is permissible to use antifreeze fluid, additives and inhibitors only if the manufacturer of these

fluids or additives guarantees they are suitable for this use and cause no damage to the heat exchanger or other com-

ponents and/or materials of the boiler unit and system. It is prohibited to use generic antifreeze fluid, additives or inhib-

itors that are not expressly suited for use in heating systems and compatible with the materials of the boiler unit and

system.

B

c

f

h

d

e

g

A

d

e

g

A

10

7

11

S QM N P

QPNL MS

R

D

C

F

E

G

H

A

B

Loading...

Loading...