Do you have a question about the Festo CiA 402 and is the answer not in the manual?

Details the device profile CiA 402 for motor controllers, including supported device types and interface information.

Explains warning, caution, and other symbols used for hazard communication and information.

Details the CAN bus interface for CiA 402, including its integration and configuration.

Covers CANopen standards and how the motor controller implements them.

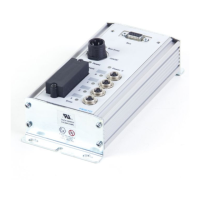

Explains the CANopen interface components, LED indicators, pin allocation, and cabling instructions.

Guides the configuration of CANopen participants using DIL switches for node ID and data rate.

Describes the process of configuring the CANopen master using EDS files.

Explains Service Data Objects (SDOs) for accessing and modifying motor controller parameters.

Details SDO sequences for reading/writing and lists SDO error messages.

Describes Process Data Objects (PDOs) for efficient, event-driven data transmission.

Lists and describes objects used for parameterizing Transmit and Receive PDOs.

Explains EMERGENCY messages for error reporting and SYNC messages for device synchronization.

Covers NMT services for controlling the motor controller's operational state and communication.

Details loading, saving, and managing parameter sets (current, default, application).

Explains the use of factor groups for converting application units to internal controller units.

Describes parameters related to the output stage, including enable logic and temperature monitoring.

Covers current regulation and motor adjustment parameters, with essential safety precautions.

Details parameters for the speed controller, including gain and time constants.

Explains the position controller, following error, and position reached functions.

Describes limiting the maximum peak current for motor operation in various modes.

Details reading digital inputs and setting digital outputs via the CAN bus.

Explains limit switch usage for reference positions and sampling actual positions.

Covers parameters for reading device type, firmware versions, and identity objects.

Explains how to configure error responses and manage error handling for motor controllers.

Introduces the compatibility_control object for maintaining compatibility with older CANopen implementations.

Illustrates the motor controller's state machine, showing statuses and transitions.

Explains the controlword's bits for triggering state transitions and actions like enabling operation.

Details the statusword bits that indicate the current device status and events.

Describes how to select and set the motor controller's operating mode (e.g., positioning, velocity, torque).

Explains the homing process for finding the initial position using various methods and parameters.

Details the Profile Position Mode, including target position, curve generator, and controller parameters.

Describes the Interpolated Position Mode for multi-axis synchronization and setpoint interpolation.

Covers speed-regulated operation, including ramp generation and speed controller parameters.

Explains how to configure speed ramps using acceleration and deceleration parameters.

Details torque-regulated operation, allowing external torque setpoints for path control.

Summarizes diagnostic messages, their codes, causes, and recommended actions.

Provides detailed instructions for clearing various faults and errors, categorized by error groups.

Lists error codes according to CiA 301/402, their corresponding messages, and reactions.

| Brand | Festo |

|---|---|

| Model | CiA 402 |

| Category | Control Unit |

| Language | English |